Question: ITI Technology designs and manufactures solid- state computer chips. In one of the production departments, employees fabricate a six- inch circular wafer by laying down

ITI Technology designs and manufactures solid- state computer chips. In one of the production departments, employees fabricate a six- inch circular wafer by laying down successive layers of silicon and then etching the circuits into the layers. Each wafer contains 100 separate solid- state computer chips. After a wafer is manufactured, the 100 chips are cut out of the wafer, tested, mounted into protective covers, and attached to electrical leads. Then a final quality control test is performed.

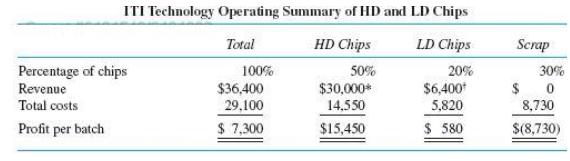

The initial testing process consists of successive stages of heating and cooling the chips and testing how they work. If 99 percent of a chip’s circuits work properly after the testing, it is classified as a high- density (HD) chip. If between 75 percent and 99 percent of a chip’s circuits work properly, it is classified as a low- density (LD) chip. If fewer than 75 percent of the circuits work, it is discarded. Twenty wafers are manufactured in a batch. On average, 50 percent of each batch are HD, 20 percent are LD, and 30 percent are discarded. HD chips are sold to defense contractors and LD chips to consumer electronics firms. Chips sold to defense contractors require different mountings, packaging, and distribution channels than chips sold to consumer electronics firms. HD chips sell for $ 30 each and LD chips sell for $ 16 each.

Each batch of 20 wafers costs $ 29,100: $ 8,000 to produce, test, and sort, and $ 21,100 for mounting, attaching leads, and final inspection and distribution costs ($ 14,500 for HD chips and $ 6,600 for LD chips). The $ 29,100 total cost per batch consists of direct labor, direct materials, and variable overhead.

The cost of scrap is charged to a plantwide overhead account, which is then allocated directly to the lines of business based on profits in each LOB.

Required:

a. Critically evaluate ITI’s method of accounting for HD and LD chips.

b. What suggestions would you offer ITI’s management?

ITI Technology Operating Summary of HD and LD Chips Total HD Chips LD Chips Scrap Percentage of chips Revenue 20% $6,400* 5,820 100% 50% 30% $36,400 29,100 $30,000* 14,550 Total costs 8,730 Profit per batch $ 7,300 $15,450 $ 580 $(8,730)

Step by Step Solution

3.59 Rating (160 Votes )

There are 3 Steps involved in it

a The major problem with ITIs accounting method is that they are allocating both joint and separable ... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (1 attachment)

364-B-M-A-D-M (1931).docx

120 KBs Word File