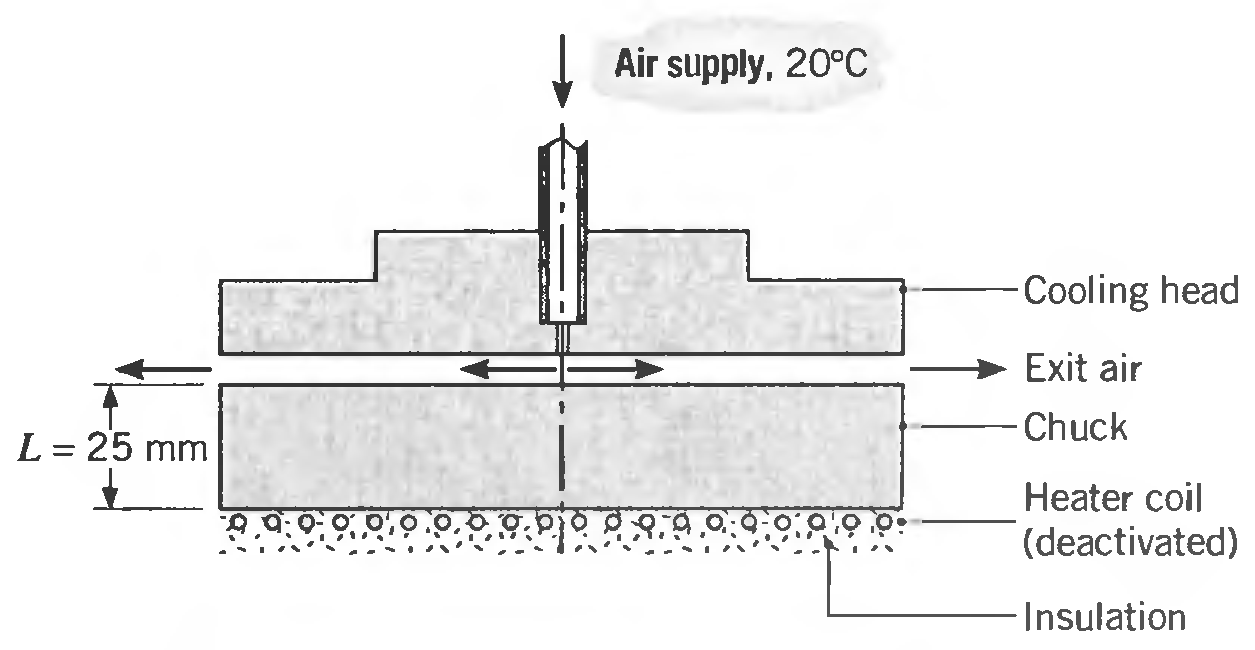

Question: Referring to the semiconductor processing tool of Problem 5.13, it is desired at some point in the manufacturing cycle to cool the chuck, which is

Referring to the semiconductor processing tool of Problem 5.13, it is desired at some point in the manufacturing cycle to cool the chuck, which is made of aluminum alloy 2024. The proposed cooling scheme passes air at 20°C between the air-supply head and the chuck surface.

(a) If the chuck is initially at a uniform temperature of 100°C, calculate the time required for its lower surface to reach 25°C, assuming a uniform convection coefficient of 50 W/m2 ∙ K at the head-chuck interface.

(b) Generate a plot of the time-to-cool as a function of the convection coefficient for the range 10 < h < 2000 W/m2 ∙ K. If the lower limit represents a free convection condition without any head present, comment on the effectiveness of the head design as a method for cooling the chuck.

Air supply, 20C Cooling head Exit air Chuck L = 25 mm Heater coil (deactivated) -Insulation

Step by Step Solution

3.27 Rating (168 Votes )

There are 3 Steps involved in it

KNOWN The chuck of a semiconductor processing tool initially at a uniform temperature of T 100C is c... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (1 attachment)

8-E-M-E-H-M-T (397).docx

120 KBs Word File