Question: The horizontal settler calculation in Example 13-7 was done for a settler diameter of (mathrm{D}_{mathrm{s}}=1.023 mathrm{~m}) with the dispersion band assumed to be at the

The horizontal settler calculation in Example 13-7 was done for a settler diameter of \(\mathrm{D}_{\mathrm{s}}=1.023 \mathrm{~m}\) with the dispersion band assumed to be at the center of the circle. The conclusion was that there was likely to be a limited amount of interference due to flow. Repeat the calculation of \(\mathrm{Re}_{\text {settler }}\) and determine whether interference is likely if the interface of the dispersion band is \(0.1 \mathrm{~m}\) below the center of the circle.

Example 13-7

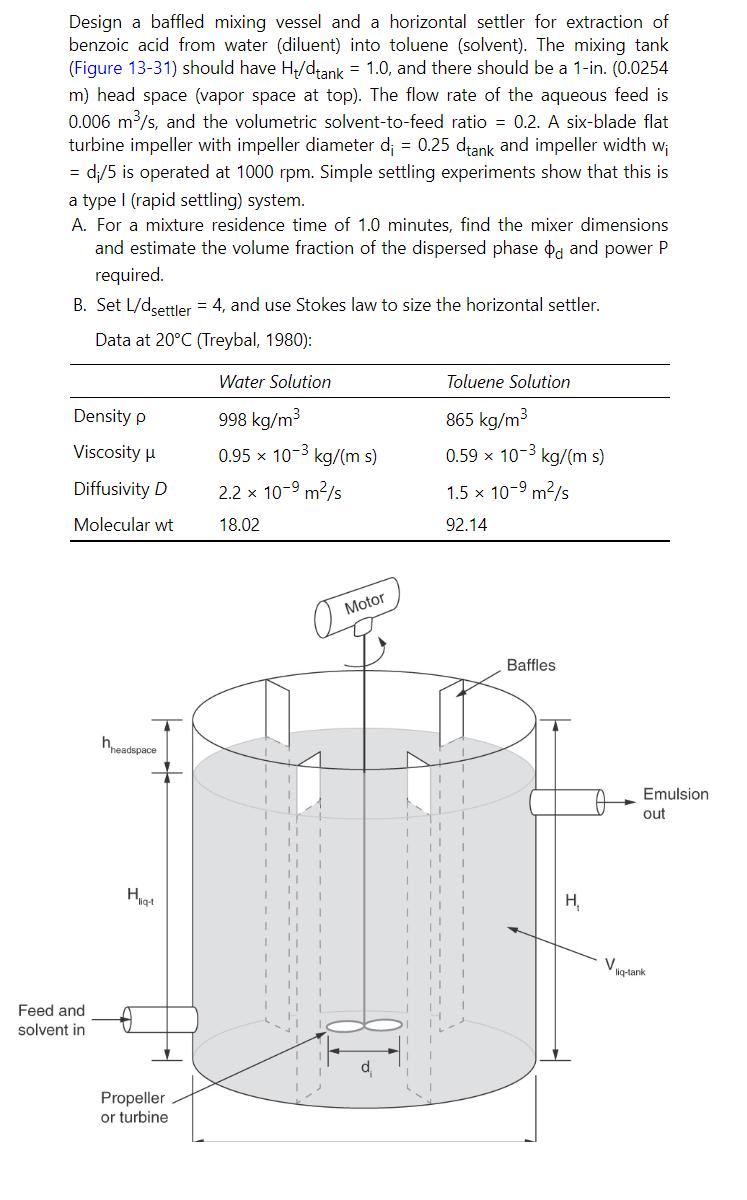

Design a baffled mixing vessel and a horizontal settler for extraction of benzoic acid from water (diluent) into toluene (solvent). The mixing tank (Figure 13-31) should have H/dtank = 1.0, and there should be a 1-in. (0.0254 m) head space (vapor space at top). The flow rate of the aqueous feed is 0.006 m/s, and the volumetric solvent-to-feed ratio = 0.2. A six-blade flat turbine impeller with impeller diameter d; = 0.25 dank and impeller width w =d/5 is operated at 1000 rpm. Simple settling experiments show that this is a type I (rapid settling) system. A. For a mixture residence time of 1.0 minutes, find the mixer dimensions and estimate the volume fraction of the dispersed phase and power P required. B. Set L/dsettler = 4, and use Stokes law to size the horizontal settler. Data at 20C (Treybal, 1980): Water Solution Density p 998 kg/m Viscosity 0.95 x 10-3 kg/(ms) Diffusivity D 22 x 10-9 m/s Molecular wt 18.02 Feed and solvent in hheadspace liq-t Motor Propeller or turbine d Toluene Solution 865 kg/m 0.59 x 10-3 kg/(ms) 1.5 x 10-9 m/s 92.14 Baffles H Vig liq-tank Emulsion out

Step by Step Solution

3.51 Rating (154 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts