It was the spring, and Shane Eten had just won a ($20,000) sustainability award at the highly

Question:

It was the spring, and Shane Eten had just won a \($20,000\) sustainability award at the highly competitive Rice University Business Plan Competition. Shane was already thinking about how he would use the \($20,000.\) This wasn’t the first time his idea, Feed Resource Recovery (feed), had won or placed well in a business plan competition—he’d finished second at the Babson College, second at the University of Colorado, and second at the UC–Berkeley competitions. Although the prize money and services in kind were helpful, Shane knew that he couldn’t successfully launch his business on prize money alone. Shane estimated that he would need \($150,000–$250,000\) to build the anaerobic digester prototype and much more money after that to scale production and sell the system across the country. Where would he get the money?

Based on his success in the business plan competitions and through strong personal networking, Shane had talked to several venture capitalists, and they all expressed strong interest in the business. Potential investors seemed to be coming out of the woodwork, but still Shane was uneasy. How much of the company would he have to give up if he was going to secure their investments? Even from his preliminary conversations with the venture capitalists, he knew that the valuation2 of the company was only going to be part of the problem. He was discouraged by the grim prospect of having to jump through hoops, answering the venture capitalists’ endless list of questions.

He figured it would take at least six months of battling back and forth over equity and shares during which time the venture capitalists would be looking over his shoulder, and all this before a prototype was ever built. Furthermore, several of the venture capitalists were saying, “This is a great idea, come back when you have a prototype built,” so Shane wasn’t even sure if they were really interested or just talking. But what other choice did he have? How could he raise the substantial amount of funding that he would require to assemble a team and build a working prototype? And how could he accomplish all of this without giving up all rights to his idea? The task was daunting, and the answers were scarce.

From Athlete to Entrepreneur: The History of Shane Eten

Shane Eten was born in Philadelphia and lived in a number of places while his father attended medical school. The family eventually settled in Cape Cod, Massachusetts, where his father and mother started a family‐owned medical practice. Living near the sea inspired Shane’s father.

My father built a sailboat in our back yard. He started when I was in sixth grade. He told me he was going to build a sailboat and sail it around the world. He was probably a little crazy, but he actually built a thirty‐six foot trimaran.3 For as long as Shane could remember, his father had a dream of building the sailboat. He would wake Shane up early in the morning on weekends and make him help work on the boat, sometimes working 12‐hour days. After several years of effort, they successfully launched it and saw it sail.

Although at the time I really hated working on that boat, looking back I realize that it was a very important part of my childhood because it taught me the importance of hard work and taking a dream you have and making it reality.

Like many boys, Shane was more interested in playing sports than school. He always enjoyed the team aspect and the competitive nature that came with athletics. His goal was to play Division I basketball in college. Hampered by knee injuries but still wanting to pursue his dream of playing college basketball, Shane chose to attend Trinity College, a Division III school, and play ball there. Unfortunately, his knees never fully recovered from a series of knee surgeries, so Shane never had a chance to play in college.

At Trinity, Shane majored in psychology. Although he enjoyed studying psychology, Shane didn’t want to pursue a career in the field, but he didn’t know exactly what he wanted.

I really didn’t enjoy school and to continue down the psychology career path would require me going back to school almost immediately. I like getting out there and getting my hands dirty with real work. In the field of psychology, I would have been doing a lot of research and theoretical education‐based work. I wasn’t ready for that. I wanted to get out in the world and make something happen.

After graduating from Trinity, Shane went on many interviews and eventually found a job working for an up‐and‐coming computer company, Angstrom Microsystems. Angstrom Microsystems built supercomputers from off‐the‐shelf components and Linux software. Shane loved working for this fast‐growing entrepreneurial company because his job was never the same day‐to‐day. He had the opportunity to work with many different aspects of the business. His original job was working with vendors. Then he moved his way up to product development, and finally he settled in customer account management. While Shane was with Angstrom, the company grew from \($500,000\) to \($15\) million in sales in his first eight months. With the hands‐on experience he gained and the opportunity of being able to see how so many aspects of a company worked, Shane realized:

Entrepreneurship is fun and, most importantly, competitive.

There’s a real science to starting a company. It was at this time that I first started thinking about building my own company.

Unfortunately, Angstrom’s success was short‐lived as the market took a turn for the worse when one of Angstrom’s largest customers stopped growing. The CFO of Angstrom left for a position at a candle company. He called Shane and convinced him to come along for the ride. The position that Shane had been offered was 180 degrees different from his job at Angstrom and an opportunity to test his abilities in a new way. Although Shane liked the tech industry, he decided to give it a shot. So at age 24 he started as a manager of a candle manufacturing plant.

It was a drastic change. Laurence Candle Company was a 60‐year‐old, third‐generation company, and I was managing people mostly older than me—some who had been working there for 30 years.

He was forced to get on the floor and get dirty learning the process of making candles.

The Laurence Candle Company was struggling because its product was very similar to another established brand, Yankee Candle. The company needed new ideas so Shane raised his hand and asked if they would give him a shot at designing a new line of candles. After doing a bunch of market research and going to trade shows to see what was out there, he launched a new line of candles made from a new type of wax made out of soy. Soy wax was environmentally friendly because the wax was made from an all‐natural crop; it was considered renewable and therefore sustainable. The soy wax candle line took off. Not only was soy cheaper than traditional paraffin wax, but also it could be sold as all‐natural for 30%–40% more than traditional candles. Sales jumped instantly. It saved the company.

There was a new consumer emerging at this time, and if you could say that it was all‐natural, then you could say that it was sustainable or noble. This new brand of customer was willing to pay a premium for environmentally friendly products.

Shane put in 60‐ to 70‐hour workweeks developing the line of soy candles. He also started research on adding biodegradable plastic wrappers to the candles. It was at this point that Shane knew if he was going to put in this much time and effort toward an idea, the next time it would be for himself and his own company.

Working for small companies, Shane had learned a lot about how the business world worked, but he knew that he needed a stronger foundation in accounting and working with numbers. If he was going to be successful in starting and managing his own ventures, he was going to have to go back for an MBA. At 28 years of age, he decided it was time to go back to school. Soon after he applied, Shane was accepted to Babson College.

The CleanTech Industry

Shane entered Babson with a goal of finding an idea to launch his own business. He was intrigued with opportunities in the Clean Technology space, especially around combating global warming.

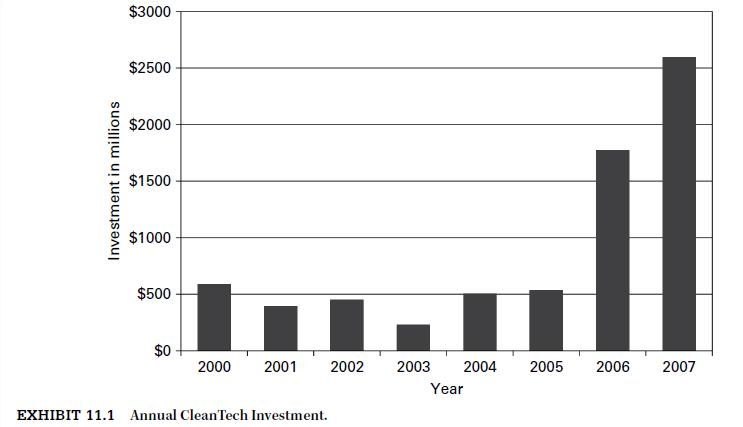

Investment and growth in the CleanTech industry exploded in 2007, passing the record set in 2006 in the first three quarters.4 Exhibit 11.1 shows an explosive upward investment trend.5 The increased growth and investment in the CleanTech industry has been brought on not only by the large price increases in gas and other fossil fuels but also by the raised awareness of global warming by prominent figures such as former Vice President Al Gore. Gore’s work with the United Nations Intergovernmental Panel on Climate Change, his winning the Nobel Peace Prize, and his involvement in the Academy Award–

winning documentary An Inconvenient Truth have brought to light the serious issues of climate change and global warming.

These works have also brought legitimacy and an increased interest in the CleanTech industry. Taken at face value, the surprisingly entertaining An Inconvenient Truth provides an idealistic, persuasive, and compelling dissection of the perils of global warming.

Frightening and timely, the smartly organized documentary is an urgent plea for responsibility and action as well as an impassioned call to heed the ominous warnings of science.6 Gore’s words resonated with Shane. As Gore stated:

But along with the danger we face from global warming, this crisis also brings unprecedented opportunities. What are the

opportunities such a crisis also offers? They include not just new jobs and new profits, although there will be plenty of both, we can build clean engines, we can harness the sun and the wind; we can stop wasting energy; we can use our planet’s plentiful coal resources without heating the planet.

The procrastinators and deniers would have us believe this will be expensive. But in recent years, dozens of companies have cut emissions of heat‐trapping gases while saving money. Some of the world’s largest companies are moving aggressively to capture the enormous economic opportunities offered by a clean energy future.

But there’s something even more precious to be gained if we do the right thing. The climate crisis also offers us the chance to experience what very few generations in history have had the privilege of knowing: a generational mission; the exhilaration of a compelling moral purpose; a shared and unifying cause; the thrill of being forced by circumstances to put aside the pettiness and conflict that so often stifle the restless human need for transcendence; the opportunity to rise.7 Consumers and the public in general are expecting companies to be more ecofriendly; they want to see real efforts made toward carbon reduction and recycling. This has encouraged companies to race toward new technologies to capture a piece of this new market.

One example of the efforts that mainstream companies are making is Google’s recent pledge to become a carbon neutral company.

Google today announced a new strategic initiative to develop electricity from renewable energy sources that will be cheaper than electricity produced from coal. The newly created initiative, known as RE

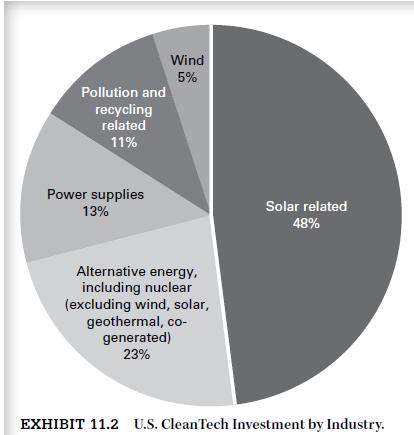

practices, the company has invested large amounts of money in green technologies. For example, Walmart installed solar power in 22 of its super centers, which accounts for roughly 1% of the U.S. super centers. Walmart has also made other green commitments promising to decrease its carbon footprint. It has pledged to eventually run off 100% of renewable energy sources. In the short run, company officials say they will adapt old stores to be 25% more efficient and new stores 30% more efficient.9 The increased interest in clean technology has attracted many investors. Exhibit 11.2 shows the distribution of investment in the CleanTech industry by subcategory.10 With the wealth of interest by angel investors and venture capitalists alike, many new companies have hit the ground running and have found success. This explains the high interest that Shane has received from these investors. The CleanTech Venture Network estimated that over 240 CleanTech companies could be positioned for a liquidity event between 2007 and 2009.11 A small niche within the CleanTech sector known as waste conversion technologies is beginning to catch on. One such example is Converted Organics Inc. Converted Organics, based in Boston, is a development‐stage company dedicated to producing a valuable all‐natural, organic soil additive through food waste recycling. Started in 2003, Converted Organics Inc.

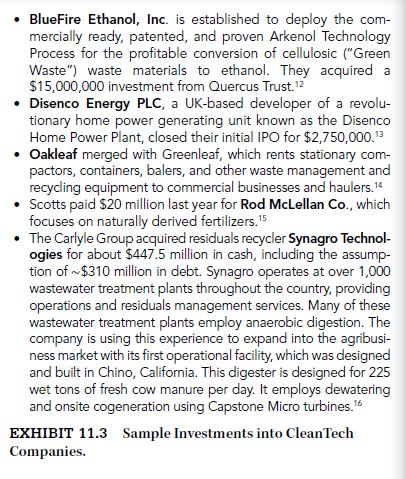

is a five‐employee operation that has just recently gone public raising \($9.9\) million in an IPO and has a market capitalization of \($14.3\) million.17 Other examples of recent transactions involving waste conversion providers are noted in Exhibit 11.3.

Roots of Feed Idea

At Babson, the entrepreneurship professors stress the importance of opportunity and an entrepreneur’s fit to that opportunity.

So Shane thought he should leverage his past experience

and start his own candle line. However, copyright laws and low profit margins discouraged him. Next, he looked at biodegradable packaging lines.

When I had an idea, I would do research for maybe three weeks, and see who else was out there, if the product was feasible, and who the customers were. I would usually find a really big obstacle. Or I just found a company that does this or a big brand that does this or someone that tried to start it and it didn’t work. And when I got to biodegradable plastic, I realized there was no way to compost it, so it wasn’t as environmentally friendly as I had first imagined. But during this search, I came across composting technology.

This seemed like a big idea and a big opportunity. The key with composting that makes it so unique is that someone is getting paid for their raw materials, which is basically trash. Companies paid to have trash hauled away, so that meant composters could get their raw material for free or even be paid to take it away.

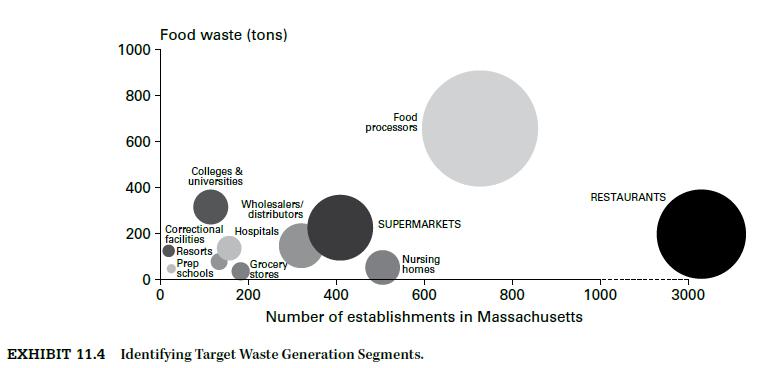

Shane started doing research into the composting industry and was intrigued by waste conversion technology. He looked at gasification, 18 plasma arc,19 aerobic composting,20 and finally anaerobic digestion.21 Anaerobic digestion caught his eye. Anaerobic digestion was a relatively proven and cheap technology, and it seemed the most viable option. Next Shane began to look at the waste stream market. He wanted to know who the largest waste producers were, what kind of waste they produced, and what the competition looked like in those industries. He looked at households and small restaurants and found that in most cases they would not generate enough waste to justify an onsite digester, and the cost of transporting the waste to a central location would be prohibitive. After further research, Shane found that the food waste produced by processing plants and supermarkets turned out to be the most promising. This was because they both were producing large amounts of food waste, and the volume was concentrated in a single location (see Exhibit 11.4).

Babson is great because there are tons of ideas floating around. The professors give us the tools to analyze whether an idea is an opportunity. You start with a problem, and if there’s a problem, there’s potentially an opportunity. So you have a bunch of students running around with two‐page summaries on their ideas, sharing their thoughts, and seeking feedback during breaks from class. The school also has a “Rocket Pitch”

event where you get three minutes to convince the audience that your idea has real potential. It takes a lot of work to learn how to pitch your concept in three minutes, but that process really helps you understand the issues around the idea.

Shane’s two‐page opportunity was about the company he wanted to start, which he called Biospan. He would build a large anaerobic digester that would be at a centralized plant, and he would collect food waste from restaurants, grocery stores, and even homes to feed the digester and produce compost and biogas. The basic idea made sense—taking waste and producing a usable by‐product. Shane decided that this idea was worth investing time and effort to really understand it. Shane applied to Babson’s Entrepreneur Intensity Track (EIT)22 program with the idea of launching this business.

Through the EIT program, Shane met with a venture capitalist who asked him tough questions like “How are you going to get six million dollars to build a big plant, and how are you going to keep Waste Management from doing it bigger and better than you?” Six million dollars was a lot of money, and Shane didn’t like the idea of competing with a company like Waste Management who did \($13\) billion in revenue each year.

By asking the right questions, Shane also realized that a large centralized plant was inefficient. Transporting the waste to the plant and then sending the energy back to users added costs, used energy (gasoline for dump trucks), and wasn’t as “Green”

as a decentralized unit located where the waste was produced.

Shane then began to look at the industry and who might gain the greatest benefit from a mobile anaerobic system. Food processors, like large pig and chicken farms, already were starting

to use anaerobic digestion systems. After more research, Shane found that grocery stores looked like the best option. They already were sorting their waste and sending it to composters, and the volume was low enough to discourage large players from entering. This seemed like a great marketplace for his decentralized systems.

You didn’t have to ask them to change their habits. They were already sorting their waste, and the system could be implemented on location without disrupting their day‐today operation.

Shane wanted to get into the industry as efficiently as possible, so he started to look for existing anaerobic systems that he could adapt to his target. He couldn’t find any systems that could handle high solid content; they were mostly set up for human or animal waste. Furthermore, those companies building these systems were targeting larger scale, centralized plants, not smaller, decentralized systems that Shane envisioned. Many people, mainly the business professionals in anaerobic digestion, were saying that decentralized systems would be too small to be effective. In Europe, they were already using anaerobic digestion for food waste but only on a large scale. From the previous business models and the waste industry’s frame of mind, the onsite model was not seen as profitable, but with the increases in energy prices and raised awareness in green tech, it started to make more sense. Shane believed if the technology could be produced, the idea would be easy to market in a food retail industry where the profit margins were razor thin and competition fierce.

The Product

The feed system, known as the R2, would utilize anaerobic digestion (AD), a clean, safe, and proven technology, to turn biodegradable waste into fuel (biogas) for a distributed electricity generation unit. AD is the breakdown of organic material by microorganisms in the absence of oxygen. Although this process occurs naturally in landfills, AD usually refers to an artificially accelerated operation that processes organic waste to produce biogas and a stable solid residue. People have been turning waste into biogas for hundreds of years, and many developing countries rely on small‐scale AD systems for cooking.

AD has grown rapidly in Europe, mostly in large centralized plants using advanced technologies. The R2 is a combination of the cheap, compact systems of India and China and the largescale, expensive, and technologically sophisticated systems of Europe: a fully automated system that enables the customers to process waste and generate energy onsite without changing current waste disposal behavior.

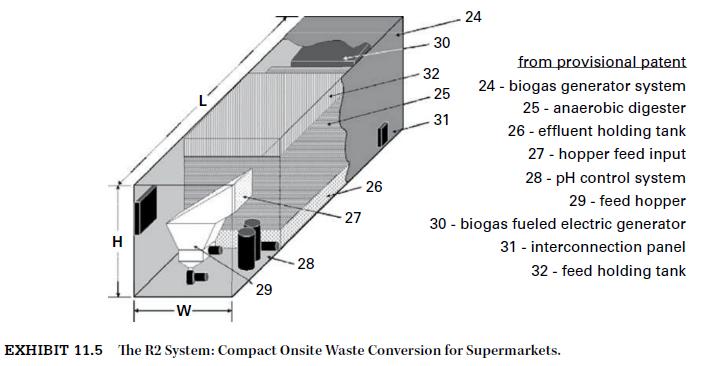

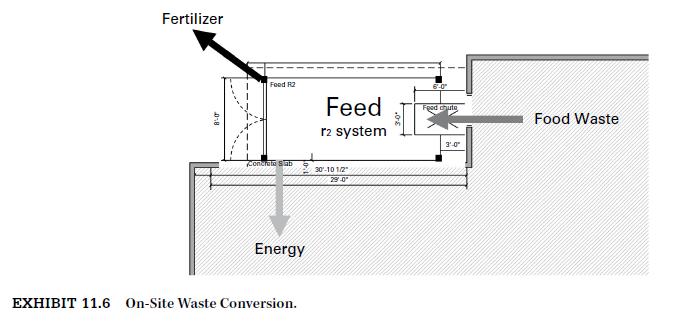

The decentralized nature of our system meant that you could place the R2 (see Exhibit 11.5) at the back of the store right in the same space that the organic waste dumpster currently occupied. It was critical to our potential customers that this system didn’t require more space or alter the footprint of the current store (see Exhibit 11.6).

The automation is made possible by the integrated control technology that operates the patented pH‐balancing unit to continually optimize system performance. Other novel and patented ideas that differentiate the system include an integrated biogas

generator unit, a gravity‐fed system that increases efficiency while reducing cost and complexity, a multi‐tank system for system reliability and flexibility, and pH balancing of the waste stream to handle diverse waste. Other than biogas, the R2 produces nutrient‐rich compost that could potentially be sold to farmers. The projected price that the grocery store would pay for its R2 was around \($300,000.

Lots\) of Interest Craig Benson, a professor at Babson, told Shane that the best way to attract investors was to go and talk to the biggest customer you could find. “If you can find a customer for your product, investors will be more than willing to get on board,”

Craig noted. Shane started to make as many connections as possible.

He called several grocery store chains in the Northeast, including Stop and Shop, Shaw’s, Walmart, and Whole Foods, but it was always hard get in front of anyone very high up in the ranks. He was always sent to someone who, even if interested, had no power to do anything about it. How could he get in front of the right person?

The success of feed in business plan competitions was also bringing a great deal of interest to his anaerobic digester idea.

Many of the venture capitalists and investors that were present at the competitions were serious about its investment possibilities.

During the Rice Business Plan Competition in the spring when feed won the sustainability award, Dow Chemical Venture Group showed an especially strong interest and said they could introduce Shane to Walmart. The Dow group flew Shane to their headquarters and put him on the phone with top executives at Walmart. Shane said the conversation went something like this:

Does it have a 24‐month payback time? I said no and they basically hung up.

The problem was that Dow and most of the venture capitalists were looking for quick returns and proven ready technology.

That meant that Shane had to figure out how to get customer payback down to two years. Moreover, once the investors realized that the final product was still in the distant future, they were reluctant to invest the time and resources needed. This meant that Shane needed to build a prototype before the venture capitalists would be interested. Shane started looking elsewhere for the needed capital.

Through the grapevine Shane heard about a Massachusetts Technology Collaborative (MTC) grant for onsite energy providers.

To be eligible you needed to meet a set power output and find a buyer for the electricity that would sign on to the project.

The MTC grant would then pay a certain amount of money for each kilowatt you could generate from the green energy method.

Shane had a connection through a friend of the family at Ring Brothers grocery store, a small local grocery store on Cape Cod.

Ring Brothers agreed to sign on as the company sponsor and feed won the grant for \($195,000.

The\) grant required that feed first run a feasibility study before it could actually start to build the prototype, and the grant provided \($20,000\) for the research study. So Shane took a look at how much actual food waste Ring Brothers produced and found that they weren’t producing enough waste to make the system feasible for the required energy output of 50 kw that was needed for the grant. Without the proper energy production output, they were forced to tell MTC that they were not going to be eligible for the \($195,000\) grant.

Team Building

Based on his experience with Ring Brothers and the knowledge that he needed to build a prototype, Shane realized that he didn’t have the skill set to do this venture on his own. He needed some technical expertise on the founding team. Shane knew that he would need an engineer to run the actual research and production of the first prototype. He needed someone who could take over a large part of the company and have the ability to get things done without supervision. A friend of Shane’s who worked at Raytheon told him that he worked with a young engineer who fit the profile that Shane was looking for.

Ryan Begin specialized in product development at Raytheon, where he led a multidisciplinary team of engineers in the integration of advanced missile defense hardware. Although Ryan enjoyed the big paycheck, he was looking for something different. Before Raytheon, Ryan had worked on multiple renewable energy—products through Clarkson University and other private organizations.

I wanted to get out of the large corporation and saw the feed concept as really interesting. It was in the green space, where I had done some work before. But most importantly, I could be on the ground floor of something potentially huge.

When they met, Shane knew that he had found the business partner he was looking for and that Ryan would be a strong addition to the team.

Ryan has the unique ability to get his hands dirty in putting the prototype together, but at the same time he is also very smart and brings a lot of expertise to the table. He has a great work ethic, and he’s the kind of guy that works so hard and is so driven that he makes you feel guilty if you’re not working just as hard.

After their initial meeting, Ryan began to run some of the numbers Shane had presented him regarding the biogas and electricity production of the suggested system. Although he found that many of numbers were on the high end of possibility, they still were within the range of having some real potential.

I could see that some of Shane’s projections were off by a lot, but the potential was there. Also the fact that he already had interested customers and investors reaffirmed my feelings that this could be a great opportunity for me.

Ryan was leaving a high‐paying job at Raytheon with stability and benefits for a job with a new company and little or no salary.

I had a choice to make, I could continue to take the safe route with Raytheon, or I could put it all on the line to test my skills and have the chance to do something big and exciting. I didn’t feel like I was doing any real engineering at Raytheon.

Being able to lead product development within the renewable energy field was very appealing to me. I could also see that Shane had real business savvy and really believed strongly in his idea and had what it would take to sell it.

To entice and reward Ryan, Shane agreed to take him on as a co‐founder and to give him some founder’s shares. After some back and forth on the amount of stock Ryan would receive in the company, they settled on 20% of the founder’s shares and the goal of paying a salary once they had raised a significant amount of investment.

Next Steps

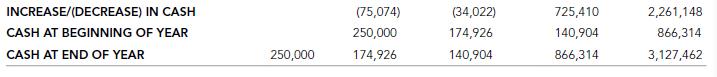

With the start of a team and a strong customer interest, Shane and Ryan knew they had to build a functioning prototype.

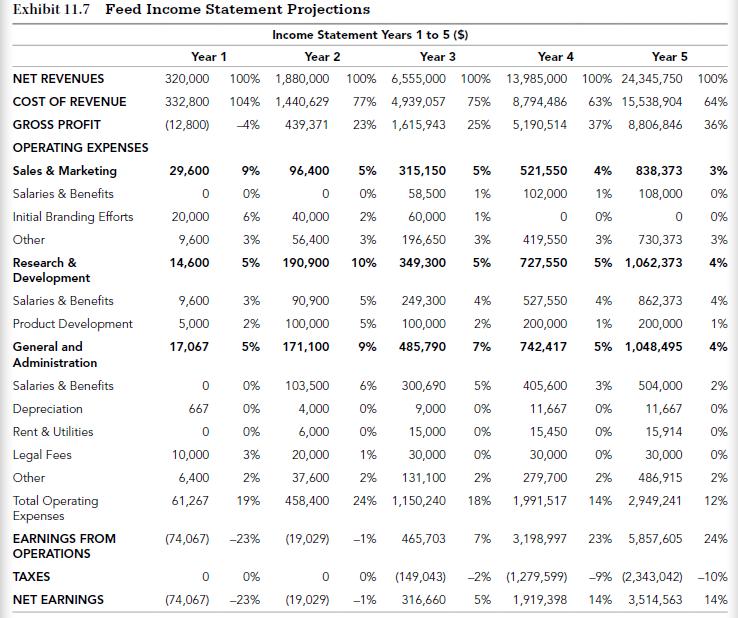

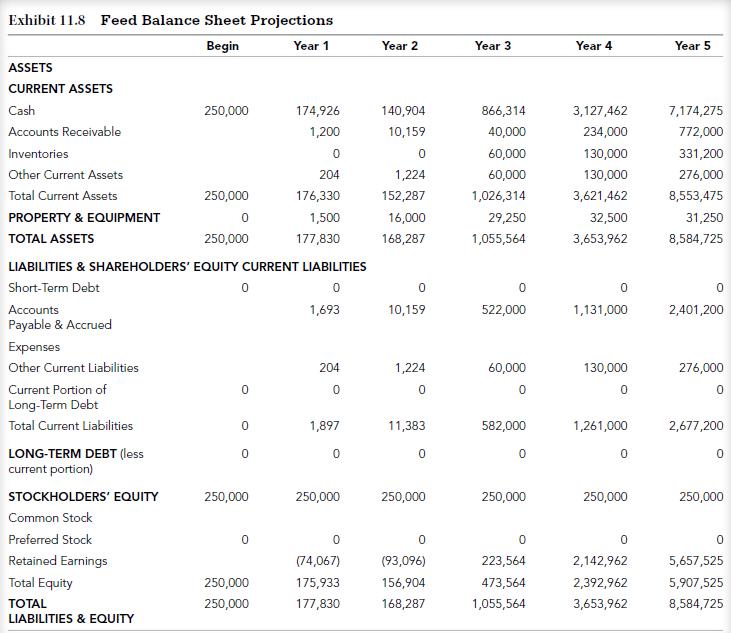

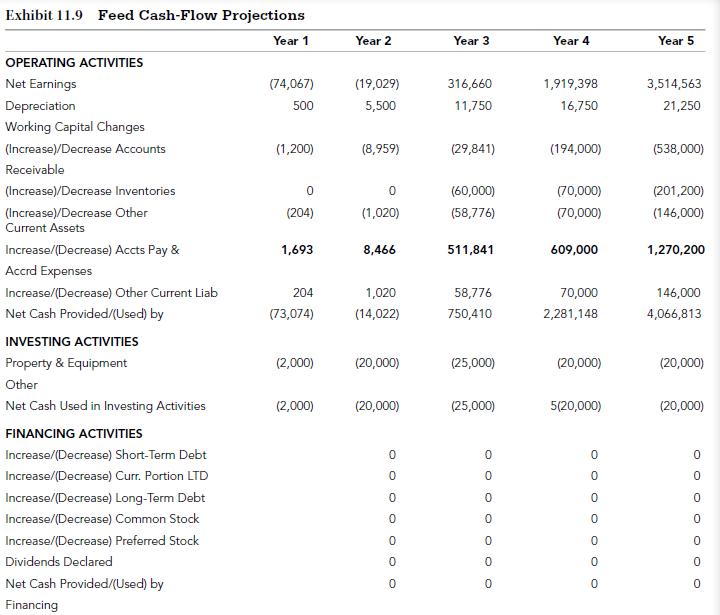

They had run some preliminary numbers and put together some pro forma financials (see Exhibits 11.7–11.9 for pro forma financials). They showed that feed needed investment now. Where could they get the \($250,000\) dollars needed to build the prototype (see Exhibit 11.8)? Although most venture capitalists wouldn’t invest at this stage, there were a few who might—but at what valuation and how long would it take to close the deal? Shane also could raise the money through family and friends, but this would take time as well.

Shane and Ryan were anxious to get started, but they knew if they couldn’t build a prototype, feed would never get off the ground.

Discussion Questions

1. Is feed an opportunity?

2. Where can Shane raise the necessary money to build the prototype?

3. What are the implications on valuation for the different sources?

Step by Step Answer: