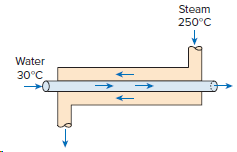

In an industrial facility a counter-flow double-pipe heat exchanger uses superheated steam at a temperature of 250°C

Question:

(a) The heat exchanger area required to maintain the exit temperature of the water to a minimum of 70°C,

(b) What would be the required heat exchanger area in case of parallel flow arrangement?

Fantastic news! We've Found the answer you've been seeking!

Step by Step Answer:

Related Book For

Fundamentals of Thermal-Fluid Sciences

ISBN: 978-0078027680

5th edition

Authors: Yunus A. Cengel, Robert H. Turner, John M. Cimbala

Question Posted: