iProtect produces covers for all makes and models of iPads. iProtect sells 1,500,000 units each year at

Question:

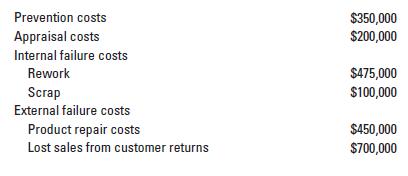

iProtect produces covers for all makes and models of iPads. iProtect sells 1,500,000 units each year at a price of $30 per unit and a contribution margin of 35%. A survey of iProtect’s customers over the past 12 months indicates that customers were very satisfied with the products, but a disturbing number of customers were disappointed because the products they purchased did not fit their iPads properly. They then had to hassle with returns and replacements. iProtect’s managers want to modify their production processes to develop products that more closely match their specifications because the quality control currently in place to prevent ill-fitting products from reaching customers is not working very well. The current costs of quality are as follows:

The controller and Quality Control manager have determined that the following additional costs will be required to modify the production process.

CAD Design improvement:..............................................................$110,000

Calibration improvement to match specifications:.....................$220,000

Required

1. Which costs-of-quality category are managers focusing on? Why?

2. If the improvements result in a 50% decrease in customer replacement cost and a 50% decrease in customer returns, what is the impact on the overall COQ and the company’s operating income? What should iProtect do? Explain.

3. Calculate prevention, appraisal, internal failure, and external failure costs as a percentage of total quality costs and as a percentage of sales before and after the change in the production process. Comment briefly on your results.

Step by Step Answer:

Horngrens Cost Accounting A Managerial Emphasis

ISBN: 9780135628478

17th Edition

Authors: Srikant M. Datar, Madhav V. Rajan