Increased global competition has spurred most firms to take a hard look at their costs and become

Question:

Increased global competition has spurred most firms to take a hard look at their costs and become “lean and mean.” Rochco, a large industrial complex, has seen offshore competition erode its market share. This industrial site of over 100 functional departments (some cost centers and others profit centers) has over the past few years undergone several restructuring and labor reduction programs in order to make the firm more cost competitive.

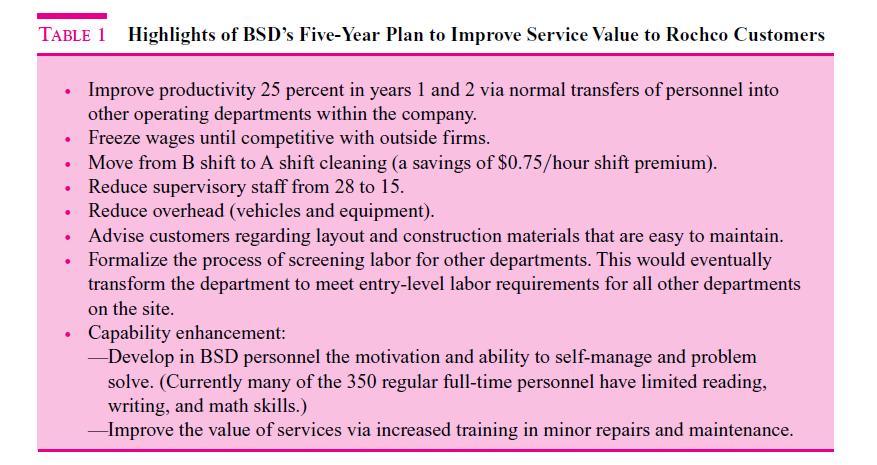

Five years ago, the many service groups supporting Rochco’s manufacturing operations were broken up into well-defined business centers. Top management encouraged all divisions to take over more decentralized decision making and mandated that the service groups provide value to the firm over outside contractors or be shut down. Dennis Flynn, manager of the building services department (BSD), was asked by Jim Corrado, general manager of Rochco operations, to describe how he would take his unit from its then-dismal position vis-à-vis outside cleaning contractors to being the cleaning service of choice for its customers. An aggressive five-year plan was developed, with break-even to be achieved in the third year. This was not an easy task considering that BSD’s costs exceeded competitors’ prices by 53 percent. Table 1 outlines the major points of the business plan.

The majority of Rochco properties are cleaned daily by BSD, which runs as a cost center allocating its expenses at full cost based on the hours of service consumed by site customers. Over 80 percent of BSD’s cost is labor (not uncommon for a cleaning service). However, BSD’s wage rates have historically been higher than competitors’ due to Rochco’s policy of paying in the upper bracket of local industry to attract good people. Flynn’s operating budget two years ago was $17 million.

Labor turnover is higher in BSD than the Rochco average (20 percent versus 5 percent annually).

The primary reason is that BSD is one of the few departments to hire labor from outside the company.

The manufacturing departments tend to recruit personnel from BSD before looking externally, for two reasons: BSD provides basic safety training and Rochco culture orientation to its people, and BSD people have been screened, inspiring confidence from hiring departments that they are good, reliable employees. The manufacturing departments also use BSD employees to fill in when normal production employees are on vacation.

Last year BSD reduced its fully absorbed costs to less than 29 percent over market prices, ahead of the forecast of 37 percent. BSD’s costs are now $15 million annually. There is more pressure than ever on all Rochco managers to reduce costs. In June,

J. William Laurri, a manufacturing manager and one of BSD’s largest customers, told Flynn that he was seriously considering going outside for cleaning services based on price. Laurri manages another cost center with challenging cost reduction goals and represents 50 percent of BSD’s customer base. Flynn is concerned that the loss of Laurri will irreparably damage BSD’s progress toward its five-year break-even goal and raise costs to other departments to such an extent that most of his customers will switch to contract cleaners. Although BSD is still uncompetitive at full cost, it is almost competitive (within 2 percent) on a direct cost basis.

Required:

a. Describe the cost accounting and control issues that are driving Flynn, Corrado, and Laurri.

b. Dennis Flynn is confident that his cost-cutting program will succeed by the target date if BSD keeps its current accounts. Should he discount BSD’s services in order to keep Laurri?

c. Should Jim Corrado insist that managers of the operating units continue to use BSD’s services? What are the pros and cons of such an order?

Step by Step Answer:

Accounting For Decision Making And Control

ISBN: 9780078136726

7th Edition

Authors: Jerold Zimmerman