What are the benefits of the cellular layout to Airline Manufacturing? Airline Manufacturing is a 275,000 ft

Question:

What are the benefits of the cellular layout to Airline Manufacturing?

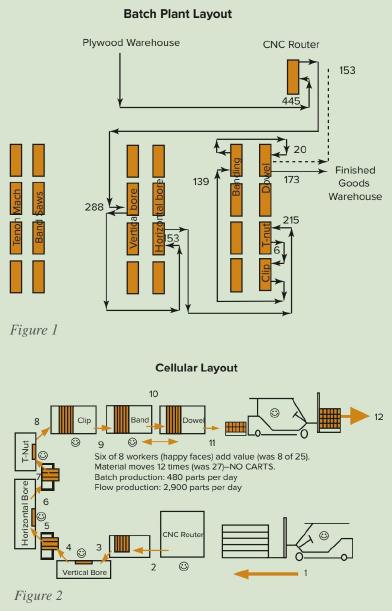

Airline Manufacturing is a 275,000 ft2, 100-employee wood component manufacturer supplying upholsterers (e.g., sofa manufacturers), and is located in Columbus, Mississippi. When Judy Dunaway took the helm of the company following her father in 2000, the company had used a batch production system for 40 years. However, the threat of competition led her to start TIT/lean manufacturing. High-run (quantity) products were identified and grouped together if their required sequences of operations were identical. The machines required for each group were located close together in a dedicated cell (flow line). As a result, the amount of WIP inventory has been cut by more than half, the number of material-handling carts has been reduced from 3,000 to 1,000, and the number of material handlers has been reduced by half. Also, manufacturing lead time is down from four weeks to less than a week.

A high-run product is part #146-3843. Consider the production of a 2,900-unit customer order. Before the layout change, batches of approximately 1,000 units were transported from the warehouse to the CNC router, and from there batches of approximately 380 units were carried, when ready, from one machine to another by two workers using heavy carts. See the batch plant layout diagram in Figure 1. These workers returned the empty carts to the originating machine. After the final operation, dowel, the finished product was transported in batches of approximately 380 units to the finished goods warehouse using forklifts. The total worker-feet of movement using the forklifts (including the return to their origin) was approximately 5,300.

After the layout change, the only transport is by forklifts bringing in and taking out the product. The total worker-feet of movement using the forklifts has remained at approximately 5,300. However, the amount of machine-to-machine material handling has been greatly reduced because the machines are located close to each other. See the cellular layout, Figure 2. Due to elimination of delays waiting for material handling, the company can now make the 2,900-unit customer order in one day whereas it used to take six days.

Step by Step Answer:

Operations Management

ISBN: 9781259270154

6th Canadian Edition

Authors: William J Stevenson, Mehran Hojati, James Cao