Question: Consider the following production process for manufacturing biscuits. The first step of the process is mixing, where all of the ingredients are combined in the

Consider the following production process for manufacturing biscuits. The first step of the process is mixing, where all of the ingredients are combined in the correct proportion to form dough. In the next step of the process, the dough is formed into sheets and cut into pieces in preparation for baking. The cut dough is then baked into biscuits and subsequently must be cooled. The final step of the process is packaging the biscuits for the consumer.

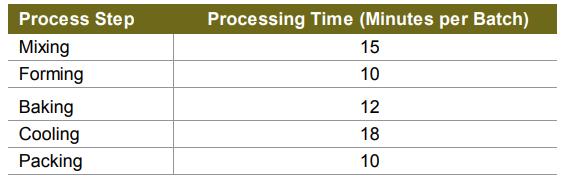

The following table summarizes the production process along with the processing times at each step of the process. The process is highly automated, so assume that this is a machine-paced process with one machine available at each step.

a. What is the capacity of the baking process step (in batches per hour)?

b. What is the bottleneck of the manufacturing process?

c. Assuming unlimited demand, what is the process flow rate (in batches per hour)?

d. Assuming unlimited demand, what is the utilization of the mixing process step?

e. If demand is 3 per hour, what is the utilization of the packing step?

f. If demand is 3 per hour, what is the cycle time (minutes) of the process?

g. If the manufacturing process is currently full of work-in-process inventory, how long would it take to complete 50 batches of biscuits?

Process Step Processing Time (Minutes per Batch) 15 Mixing 10 Forming 12 Baking 18 Cooling 10 Packing

Step by Step Solution

3.35 Rating (164 Votes )

There are 3 Steps involved in it

a 5 batches per hour Since there is only one machine at each process step the capacity is the recipr... View full answer

Get step-by-step solutions from verified subject matter experts