Nautique Boat Company, headquartered on a 200-acre campus with two lakes, is the leading manufacturer of waterskiing,

Question:

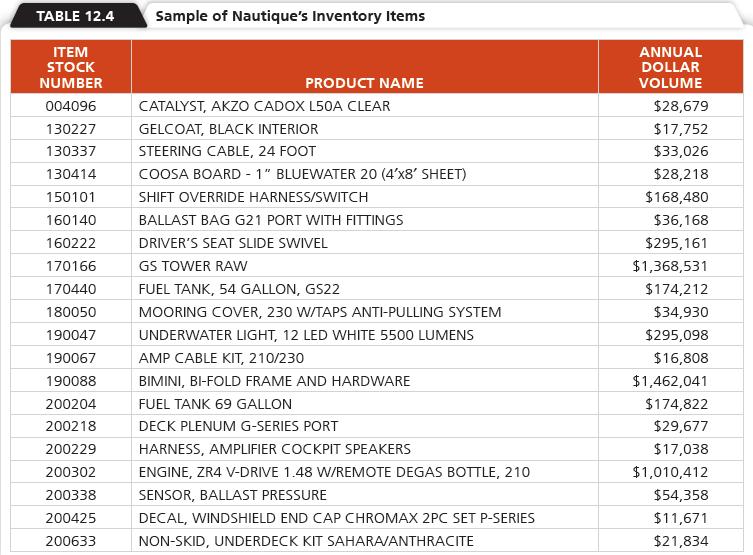

Nautique Boat Company, headquartered on a 200-acre campus with two lakes, is the leading manufacturer of waterskiing, wakeboarding, and wake-surfing boats in the U.S. Since the 1962 introduction of its now iconic $80,000 Ski Nautique line, the company has expanded with new products every year, most recently with its top-of-the line $300,000 Paragon P23. Known for setting industry standards in quality and innovation (see the Global Company Profile on Nautique’s new product development that opens Chapter 5), the firm takes inventory control very seriously. It holds $10–$11 million in inventory at any given time, plus another $2 million in spare parts to support customer needs for boats no longer in production. There are a total of 2,600 SKUs in inventory for ongoing production (about 1,000–1,200 per boat) and past customer support. Managing the massive warehouse, full from floor to 16-foothigh storage racks, is the responsibility of Materials and Supply Chain Manager Drew Pope. Drew, a young engineer who bought his first Nautique as a teen and spent four years rebuilding it, uses the ABC method to categorize his wide range of parts, their lead times, and their storage locations. Drew’s top SKUs in terms of annual dollar volume are: engines ($43 million), fiberglass/resins/composites ($13 million), towers ($12 million), audio systems ($8 million), Biminis and mooring covers ($6 million), navigation equipment ($5 million), plastics ($5 million), electronics/wiring ($5 million), nonskid decking ($4 million), and seat foam ($3 million). Nautique’s continuing stream of innovative and special ordered boats adds complexity to the inventory challenge, but with tight controls and cycle counts each Friday, Drew manages to turn inventory 18–19 times per year. As a result, Nautique has been able to obtain an inventory accuracy level of 99.7% of dollar value. Table 12.4 provides a sampling of the 2,600 SKUS used in active production. Bulk goods, such as fiberglass, resins, and brackets, are all vendor-managed inventory (VMI), replenished at least twice a week.

Discussion Questions

1. Conduct an ABC analysis on the 20 SKUs listed in Table 12.4.

2. Why would Nautique use vendor-managed inventory for some of its SKUs?

3. Should Nautique consider vertically integrating suppliers of the top annual dollar volume inventory items? What are the advantages and disadvantages of this decision? (For example, Nautique’s parent company has purchased Performance Custom Marine (PCM) engines.)

4. How could Nautique reduce the number of SKUs it manages?

Step by Step Answer:

Operations Management Sustainability And Supply Chain Management

ISBN: 9780137476442

14th Edition

Authors: Jay Heizer, Barry Render, Chuck Munson