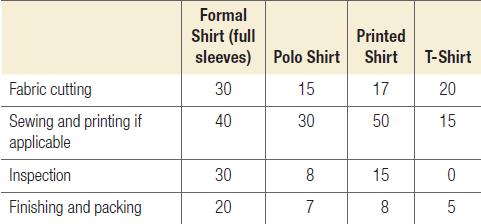

Question: Returning to Problem 5, if weekly demand for the four shirts is formal shirt = 5 units, polo shirt = 25 units, printed shirt =

Returning to Problem 5, if weekly demand for the four shirts is formal shirt = 5 units, polo shirt = 25 units, printed shirt = 10 units, and T-shirt = 82 units, which activity is the bottleneck now, and is the factory capable of producing all the shirts demanded? How many additional number of T-shirts will the factory be able to produce? Will there be any change in the bottleneck?

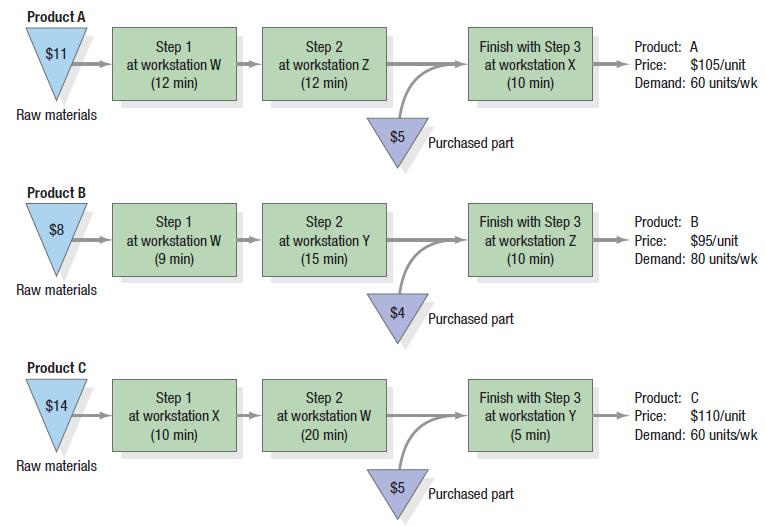

weekly demand, and processing times) and process sequences are shown in Figure 6.13. Raw materials and purchased parts (shown as a per-unit consumption rate) are represented by inverted triangles. YPI is able to make and sell up to the limit of its demand per week with no penalties incurred for not meeting the full demand. Each workstation is staffed by one highly skilled worker who is dedicated to work on that workstation alone and is paid $15 per hour. The plant operates one 8-hour shift per day and operates on a 5-day workweek (i.e., 40 hours of production per person per week). Overhead costs are $9,000/ week. Which of the four workstations, W, X, Y, or Z, has the highest aggregate workload, and thus serves as the bottleneck for YPI?

Data from problem 5

A garment tailoring company in Shanghai specializes in four types of shirts, namely formal shirts, polo shirts, printed shirts, and T-shirts. The following table shows how long it takes to process each shirt through each required activity. Note that all times are in minutes. The factory is open 8 hours a day, 6 days a week.

If the factory makes only T-shirts during summer to meet high demand, what would be its production capacity? If weekly demand for the four shirts is formal shirt = 20 units, polo shirt = 15 units, printed shirt = 10 units, and T-shirt = 72 units, which activity is the bottleneck, and is it capable of producing all the shirts demanded?

Product A $11 Raw materials Product B $8 Raw materials Product C $14 Raw materials Step 1 at workstation W (12 min) Step 1 at workstation W (9 min) Step 1 at workstation X (10 min) Step 2 at workstation Z (12 min) Step 2 at workstation Y (15 min) Step 2 at workstation W (20 min) $5 Finish with Step 3 at workstation X (10 min) Purchased part Finish with Step 3 at workstation Z (10 min) $4 Purchased part Finish with Step 3 at workstation Y (5 min) $5 Purchased part Product: A Price: $105/unit Demand: 60 units/wk Product: B Price: $95/unit Demand: 80 units/wk Product: C Price: $110/unit Demand: 60 units/wk

Step by Step Solution

3.45 Rating (152 Votes )

There are 3 Steps involved in it

To find the bottleneck in the production process and whether the factory is capable of meeting the demand for the shirts we need to calculate the total processing time for each type of shirt and the c... View full answer

Get step-by-step solutions from verified subject matter experts