Question: Revisit the worked example earlier in the chapter that analyzed a journey in terms of value-added time (actually going somewhere) and non-value-added time (the time

Revisit the worked example earlier in the chapter that analyzed a journey in terms of value-added time (actually going somewhere) and non-value-added time (the time spent queueing, etc.).

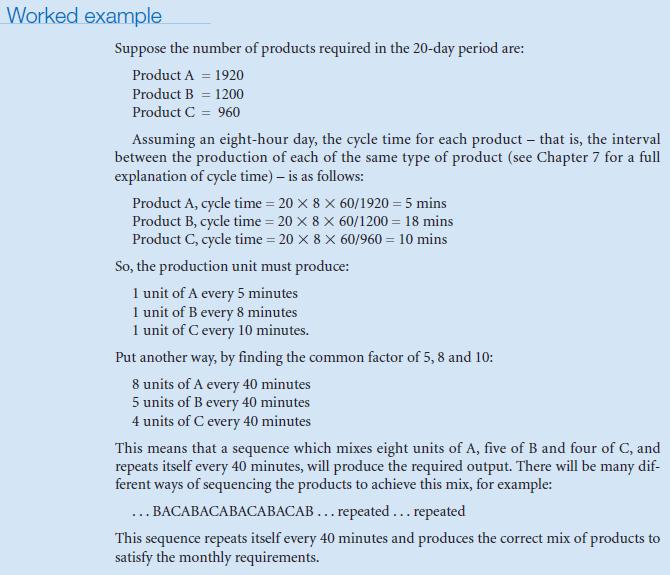

Worked example Suppose the number of products required in the 20-day period are: Product A = 1920 Product B = 1200 Product C = 960 Assuming an eight-hour day, the cycle time for each product that is, the interval between the production of each of the same type of product (see Chapter 7 for a full explanation of cycle time) - is as follows: Product A, cycle time=20 X 8 X 60/1920 = 5 mins Product B, cycle time=20 x 8 x 60/1200 = 18 mins Product C, cycle time=20 X 8 X 60/960 = 10 mins So, the production unit must produce: 1 unit of A every 5 minutes 1 unit of B every 8 minutes 1 unit of C every 10 minutes. Put another way, by finding the common factor of 5, 8 and 10: 8 units of A every 40 minutes 5 units of B every 40 minutes 4 units of C every 40 minutes This means that a sequence which mixes eight units of A, five of B and four of C, and repeats itself every 40 minutes, will produce the required output. There will be many dif- ferent ways of sequencing the products to achieve this mix, for example: ...BACABACABACABACAB... repeated... repeated This sequence repeats itself every 40 minutes and produces the correct mix of products to satisfy the monthly requirements.

Step by Step Solution

3.35 Rating (155 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts