Ride Gear Limited, based in Ontario. manufactures after-market accessories for motorcycles, such as fairings, hand guards. seats,

Question:

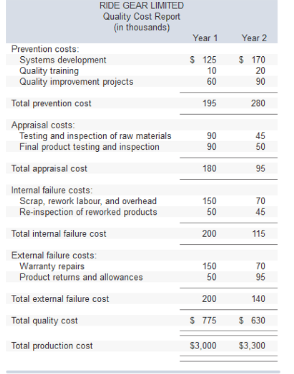

Ride Gear Limited, based in Ontario. manufactures after-market accessories for motorcycles, such as fairings, hand guards. seats, and cargo carriers In its early years of operation. Ride Gear had a reputation for outstanding product quality. which is a key determinant of success in this industry Competition has become extremely intense in recent years. and Ride Gear has lost market share to companies based in China In a recent survey of product quality conducted by a leading motorcycle magazine. Ride Gear slipped to fifth place among the top 10 accessory manufacturers In response to the disappointing results from the market survey. the president of Ride Gear. Dave Rankin. decided to take action in an effort to improve product quality. One of his first steps was to set up a quality improvement team to identify key areas where changes were most needed Rankin remembered from his managerial accounting course in university that high quality of conformance is the overall objective and that different types of quality costs can interact to improve quality. However. beyond these basic details. Rankin's recollection of quality costs was limited. so he appointed Gale Smith to lead the quality improvement team and make the changes needed to allow Ride Gear to better compete. Smith's quality improvement program has now been in operation for two years. The company's most recent quality cost report is shown below.

Required:

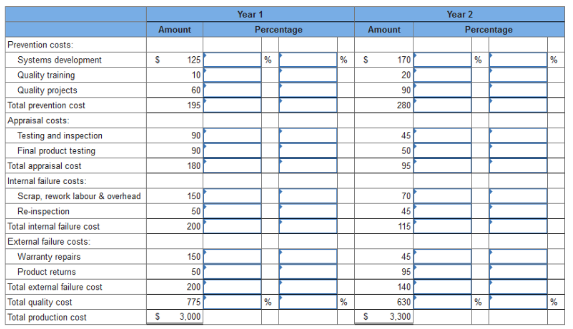

1. Prepare percentage analysis of the company's quality cost report with percentage figures in two ways: first, as a percentage of total production cost: and second. as a percentage of the total quality cost if Ride Gear's quality improvement program has been successful. (Round your answers to 1 decimal place.)

2. Based on the analysis performed in (requirement 1) above, has Smith?s quality improvement program been successful to date?

Yes

No

Vector Mechanics for Engineers Statics and Dynamics

ISBN: 978-0073212227

8th Edition

Authors: Ferdinand Beer, E. Russell Johnston, Jr., Elliot Eisenberg, William Clausen, David Mazurek, Phillip Cornwell