Question: You are a newly minted design engineer working with a bridge design firm. As a part of your training you are instructed to design a

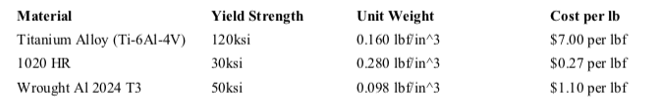

You are a newly minted design engineer working with a bridge design firm. As a part of your training you are instructed to design a girder for a new bridge project. You are given the vehicle load, weight per unit length, and the dimensions of the cross-section of the girder. You are asked to determine, for three materials, the maximum length cross-section of the girder. You are asked to determine, for three materials, the maximum length of the girder that that will maintain a safety factor, n d , of 3. The safety factor is calculated as follows

Nd = ? rs / ? von

where ? von is the von Mises Stress.

Structure of Report

Draw and properly label a Free Body Diagram (include arrows indicate where external forces are transmitted and how they transmitted)

List the Number of Known's and Unknown?s (assume the external forces and moments are known)

Write the Equations of Equilibrium (Sum of the Force, Sum of Moments)

Draw the shear and bending moment diagrams.

Find the location along the beam where the shear force and bending moments are maximized.

Identify the critical locations along the cross-section.

Calculate the State of Stress at these critical locations.

Calculate the Von Mises stress at these critical locations.

Identify where Von Mises stress is highest.

Check for safety.

Determine the optimal length for the three materials.

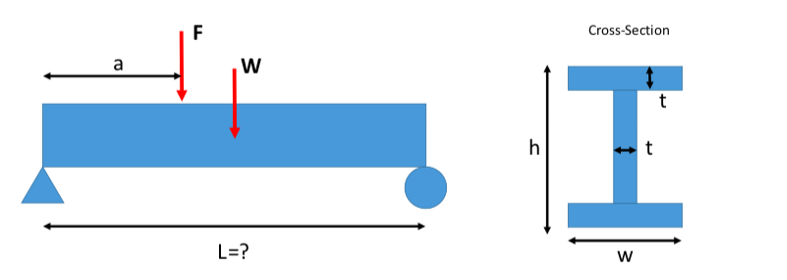

Figure 2 - Schematic of a 1-Beam girder. Weight is assumed to a single concentrated force at the middle of the bridge. The vehicle load travels across the bridge from zero to L meters.

Beam Dimensions h = 382mm, w = 328mm, t = 32.6mm, l x = 100510cm 4

Vehicle Load F = 100KN

Note: Material properties are given in English units. Do the math and answers in Metric units.

a F ,W L=? h Cross-Section HI W Material Titanium Alloy (Ti-6Al-4V) 1020 HR Wrought Al 2024 T3 Yield Strength 120ksi 30ksi 50ksi Unit Weight 0.160 lbfin^3 0.280 lbf in^3 0.098 lbfin^3 Cost per lb $7.00 per lbf $0.27 per lbf $1.10 per lbf

Step by Step Solution

3.54 Rating (154 Votes )

There are 3 Steps involved in it

To solve this problem follow these detailed steps Step 1 Draw the Free Body Diagram FBD Support Forces Since the beam is simply supported it has a pin ... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (2 attachments)

608fceaa7bfd3_21297.pdf

180 KBs PDF File

608fceaa7bfd3_21297.docx

120 KBs Word File