Question: 04 (25%. Non linear Programming): welded plate girders are widely used in highway and railway bridges. It has been determined that the lifecycle cost of

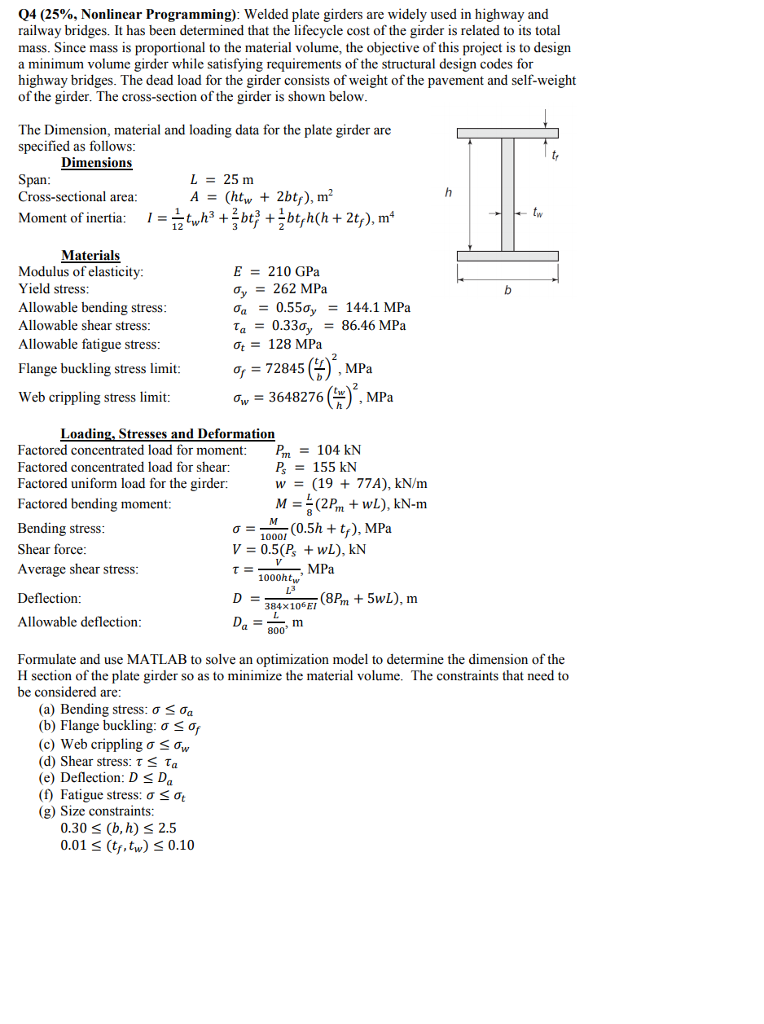

04 (25%. Non linear Programming): welded plate girders are widely used in highway and railway bridges. It has been determined that the lifecycle cost of the girder is related to its total mass. Since mass is proportional to the material volume, the objective of this project is to design a minimum volume girder while satisfying requirements of the structural design codes for highway bridges. The dead load for the girder consists of weight of the pavement and self-weight of the girder. The cross-section of the girder is shown below The Dimension, material and loading data for the plate girder are specified as follows Dimensions L25 m pan Cross-sectional area: Moment of inertia I- 12 Materials Modulus of elasticity: Yield stress: Allowable bending stress Allowable shear stress: Allowable fatigue stress: Flange buckling stress limit: E , 210 GPa 262 MPa = 0.55Jy = 144.1 MPa Ta - 0.33a86.46 MPa t128 MPa or = 72845 (). MPa Web crippling stress limit: 3648276 (te)", MPa Loading, Stresses and Deformation 104 kN Factored concentrated load for moment Factored concentrate Factored uniform load for the girder: Factored bending moment Bending stress Shear force Average shear stress P 155 kN w(19 + 77A), kN/m d load for shear: 710007(0.5h + tj). MPa V = 0.5(B + WL), KN MPa 1000htw Deflection: 84x106EI Om Allowable deflection (7 800 Formulate and use MATLAB to solve an optimization model to determine the dimension of the H section of the plate girder so as to minimize the material volume. The constraints that need to be considered are: (a) Bending stress: (b) Flange buckling: (c) Web crippling (d) Shear stress: (e) Deflection: D s Da (f) Fatigue stress: Oz (g) Size constraints: 0.30 S (b, h) S 2.5 0.01 S (tftw) S 0.10 04 (25%. Non linear Programming): welded plate girders are widely used in highway and railway bridges. It has been determined that the lifecycle cost of the girder is related to its total mass. Since mass is proportional to the material volume, the objective of this project is to design a minimum volume girder while satisfying requirements of the structural design codes for highway bridges. The dead load for the girder consists of weight of the pavement and self-weight of the girder. The cross-section of the girder is shown below The Dimension, material and loading data for the plate girder are specified as follows Dimensions L25 m pan Cross-sectional area: Moment of inertia I- 12 Materials Modulus of elasticity: Yield stress: Allowable bending stress Allowable shear stress: Allowable fatigue stress: Flange buckling stress limit: E , 210 GPa 262 MPa = 0.55Jy = 144.1 MPa Ta - 0.33a86.46 MPa t128 MPa or = 72845 (). MPa Web crippling stress limit: 3648276 (te)", MPa Loading, Stresses and Deformation 104 kN Factored concentrated load for moment Factored concentrate Factored uniform load for the girder: Factored bending moment Bending stress Shear force Average shear stress P 155 kN w(19 + 77A), kN/m d load for shear: 710007(0.5h + tj). MPa V = 0.5(B + WL), KN MPa 1000htw Deflection: 84x106EI Om Allowable deflection (7 800 Formulate and use MATLAB to solve an optimization model to determine the dimension of the H section of the plate girder so as to minimize the material volume. The constraints that need to be considered are: (a) Bending stress: (b) Flange buckling: (c) Web crippling (d) Shear stress: (e) Deflection: D s Da (f) Fatigue stress: Oz (g) Size constraints: 0.30 S (b, h) S 2.5 0.01 S (tftw) S 0.10

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts