Question: 1. 2. 3. 4. The supervisor at the Precision Machine Shop wants to determine the staffing policy that minimizes total operating costs. The average arrival

1.

2.

3.

4.

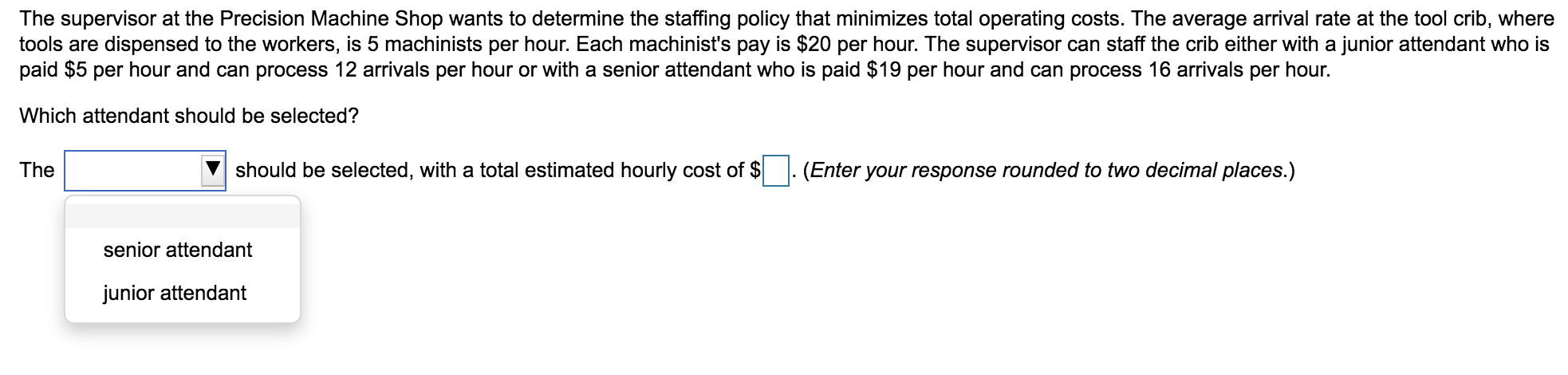

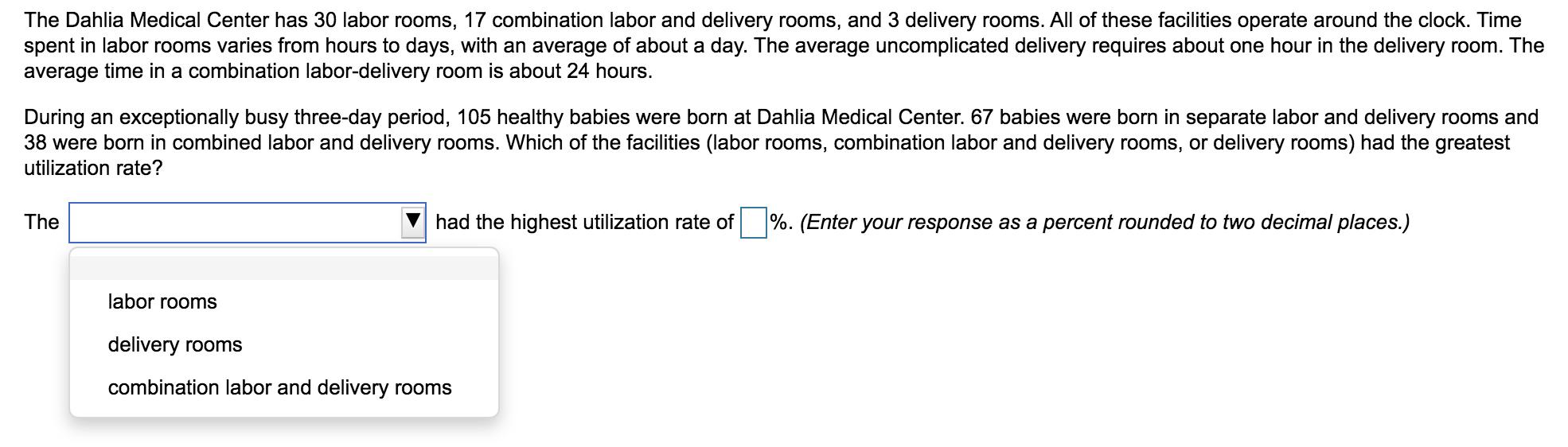

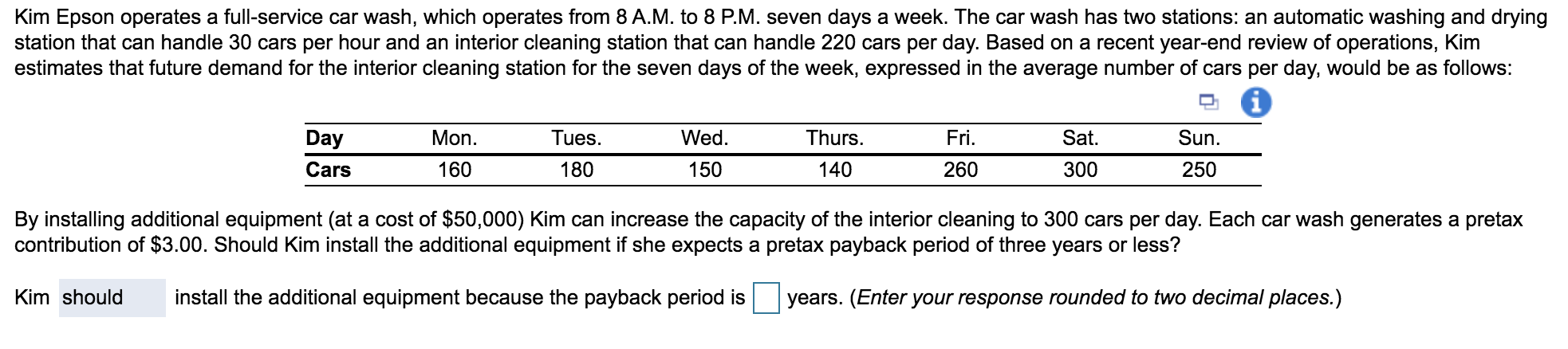

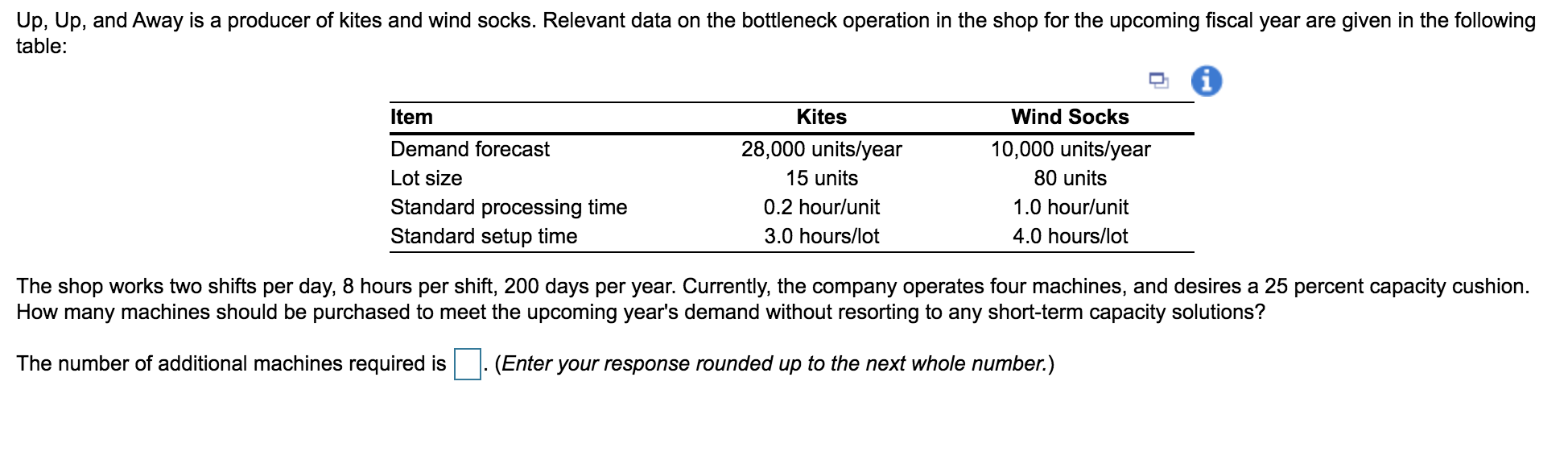

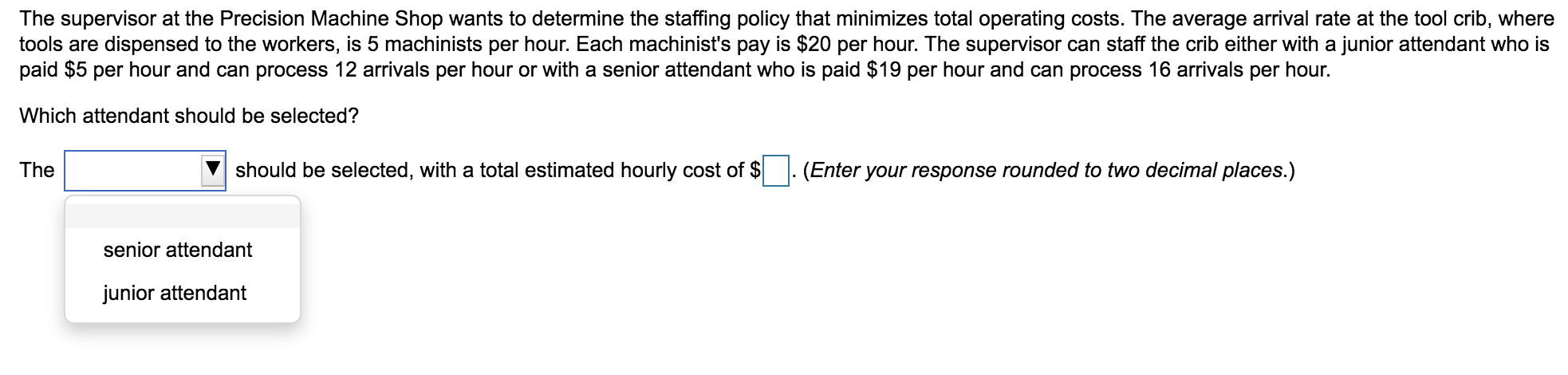

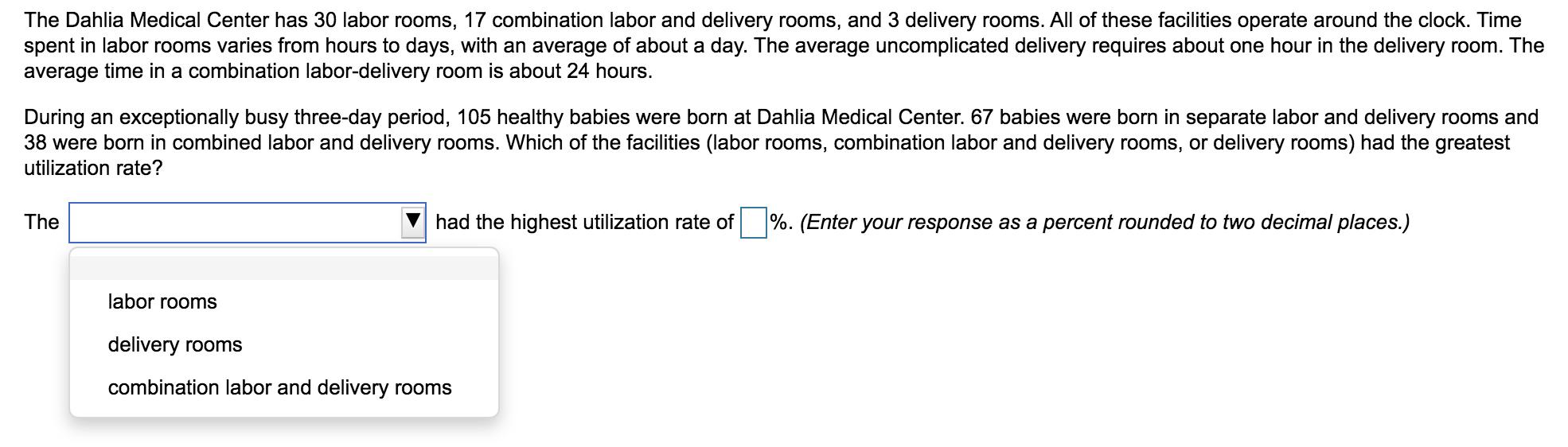

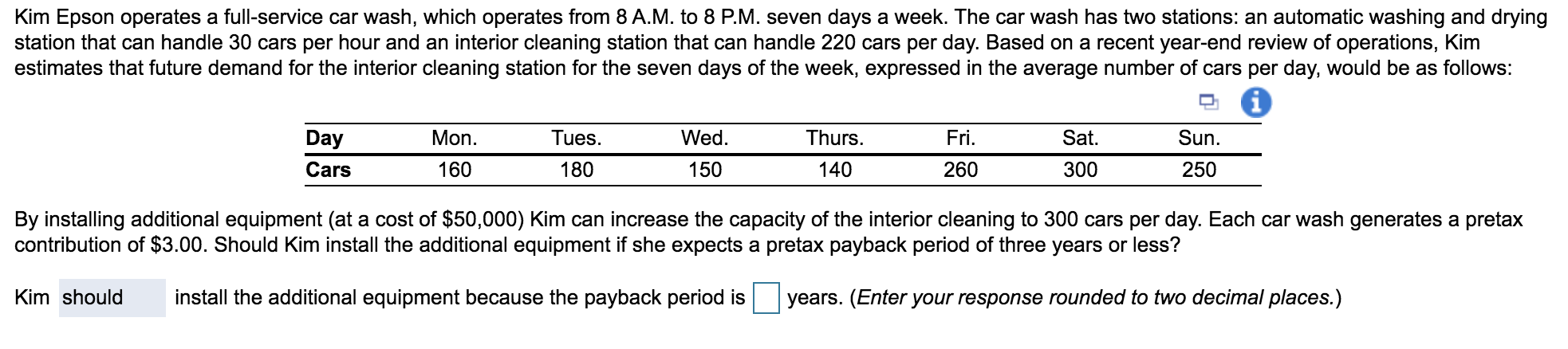

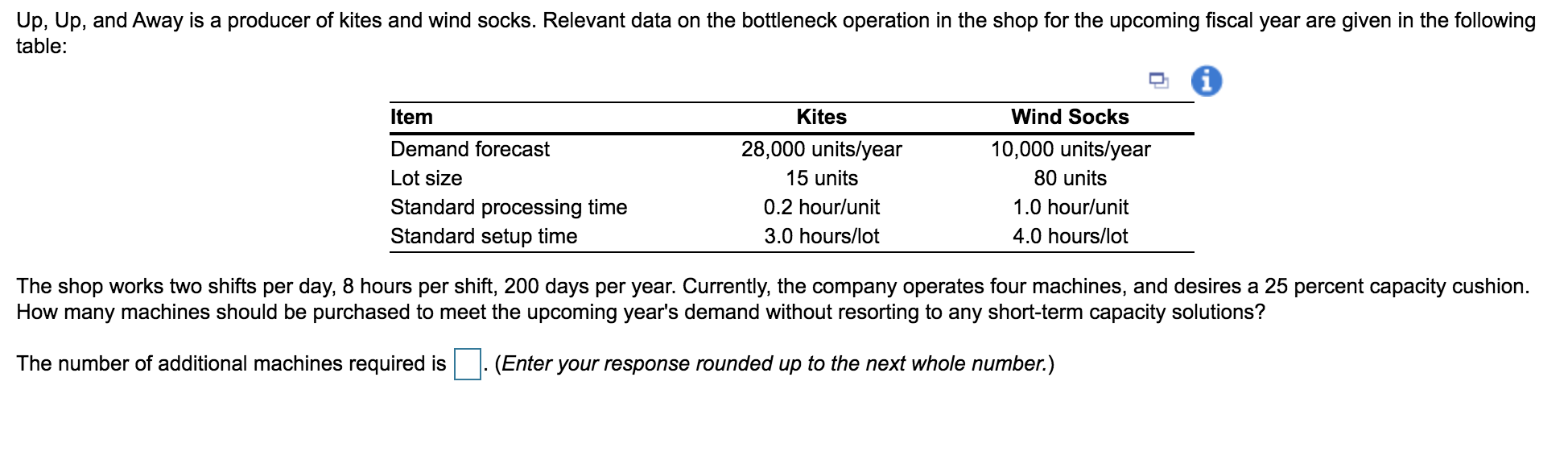

The supervisor at the Precision Machine Shop wants to determine the staffing policy that minimizes total operating costs. The average arrival rate at the tool crib, where tools are dispensed to the workers, is 5 machinists per hour. Each machinist's pay is $20 per hour. The supervisor can staff the crib either with a junior attendant who is paid $5 per hour and can process 12 arrivals per hour or with a senior attendant who is paid $19 per hour and can process 16 arrivals per hour. Which attendant should be selected? The V should be selected, with a total estimated hourly cost of $ . (Enter your response rounded to two decimal places.) senior attendant junior attendant The Dahlia Medical Center has 30 labor rooms, 17 combination labor and delivery rooms, and 3 delivery rooms. All of these facilities operate around the clock. Time spent in labor rooms varies from hours to days, with an average of about a day. The average uncomplicated delivery requires about one hour in the delivery room. The average time in a combination labor-delivery room is about 24 hours. During an exceptionally busy three-day period, 105 healthy babies were born at Dahlia Medical Center. 67 babies were born in separate labor and delivery rooms and 38 were born in combined labor and delivery rooms. Which of the facilities (labor rooms, combination labor and delivery rooms, or delivery rooms) had the greatest utilization rate? The V had the highest utilization rate of %. (Enter your response as a percent rounded to two decimal places.) labor rooms delivery rooms combination labor and delivery rooms Kim Epson operates a full-service car wash, which operates from 8 A.M. to 8 P.M. seven days a week. The car wash has two stations: an automatic washing and drying station that can handle 30 cars per hour and an interior cleaning station that can handle 220 cars per day. Based on a recent year-end review of operations, Kim estimates that future demand for the interior cleaning station for the seven days of the week, expressed in the average number of cars per day, would be as follows: Day Cars Mon. 160 Tues. 180 Wed. 150 Thurs. 140 Fri 260 Sat 300 Sun. 250 By installing additional equipment (at a cost of $50,000) Kim can increase the capacity of the interior cleaning to 300 cars per day. Each car wash generates a pretax contribution of $3.00. Should Kim install the additional equipment if she expects a pretax payback period of three years or less? Kim should install the additional equipment because the payback period is years. (Enter your response rounded to two decimal places.) Up, Up, and Away is a producer of kites and wind socks. Relevant data on the bottleneck operation in the shop for the upcoming fiscal year are given in the following table: a Item Kites Wind Socks Demand forecast 28,000 units/year 10,000 units/year Lot size 15 units 80 units Standard processing time 0.2 hour/unit 1.0 hour/unit Standard setup time 3.0 hours/lot 4.0 hours/lot The shop works two shifts per day, 8 hours per shift, 200 days per year. Currently, the company operates four machines, and desires a 25 percent capacity cushion. How many machines should be purchased to meet the upcoming year's demand without resorting to any short-term capacity solutions? The number of additional machines required is . (Enter your response rounded up to the next whole number.)