Question: 1 . 2 Two models ( Model 1 and Model 2 ) of a product are to be produced on an assembly line. Because of

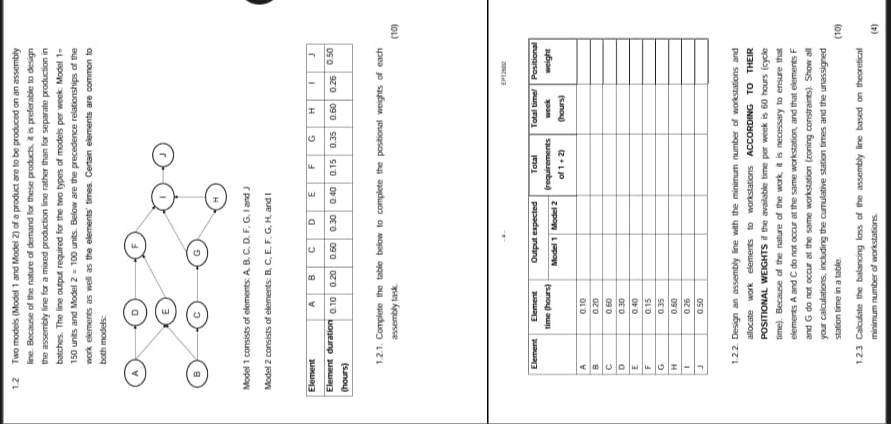

Two models Model and Model of a product are to be produced on an assembly line. Because of the nature of demand for these products, it is preferable to design the assembly line for a mixed production line rather than for separate production in batches. The line output required for the two types of models per woek: Model units and Model units. Below are the precedence relationships of the work elements as well as the elements' times. Certain elements are common to both models: Model consists of elements: A B C D F G I and J Model consists of elements: B C E F G H and I Complete the table below to complete the positional weights of each assembly lask.Element time hoursTotal requirements of Total timel week hoursPositional weight Design an assembly line with the minimum number of workstations and allocate work elements to workstations ACCORDING TO THEIR POSIMONAL WEIGHTS if the available time per week is hours cycle time Because of the nature of the work, it is necessary to ensure that elements A and C do not occur at the same workstation, and that elements F and G do not occur at the same workstation zoning constraints Show all your calculations, including the curnulative station times and the unassigned station time in a table. Calculate the balancing loss of the assembly line based on theoretical minimum number of workstations.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock