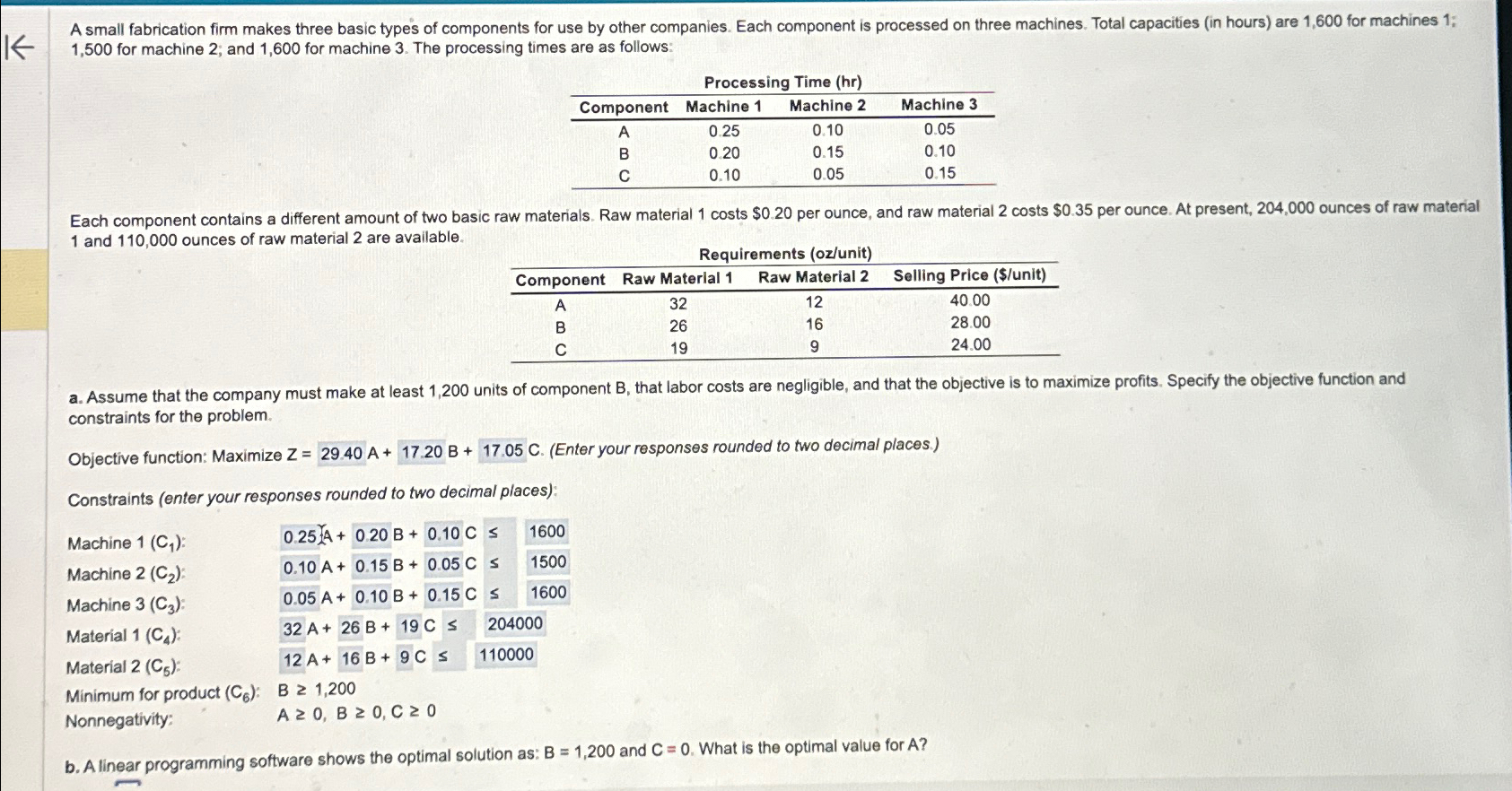

Question: 1 , 5 0 0 for machine 2 ; and 1 , 6 0 0 for machine 3 . The processing times are as follows:

for machine ; and for machine The processing times are as follows:

Processing Time hr

tableComponentMachine Machine Machine ABC

and ounces of raw material are available.

Requirements ozunit

tableRequirements ozunitComponentRaw Materlal Raw Material Selling Price $unitABC

constraints for the problem.

Objective function: Maximize Enter your responses rounded to two decimal places.

Constraints enter your responses rounded to two decimal places:

Machine :

Machine :

Machine :

Material :

table

Material :

Minimum for product :

Nonnegativity:

b A linear programming software shows the optimal solution as: and What is the optimal value for

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock