Question: 1 5 3 points 0 1 : 1 9 : 0 6 In a food processing facility, a supervisor notices that a worker frequently waits

points

::

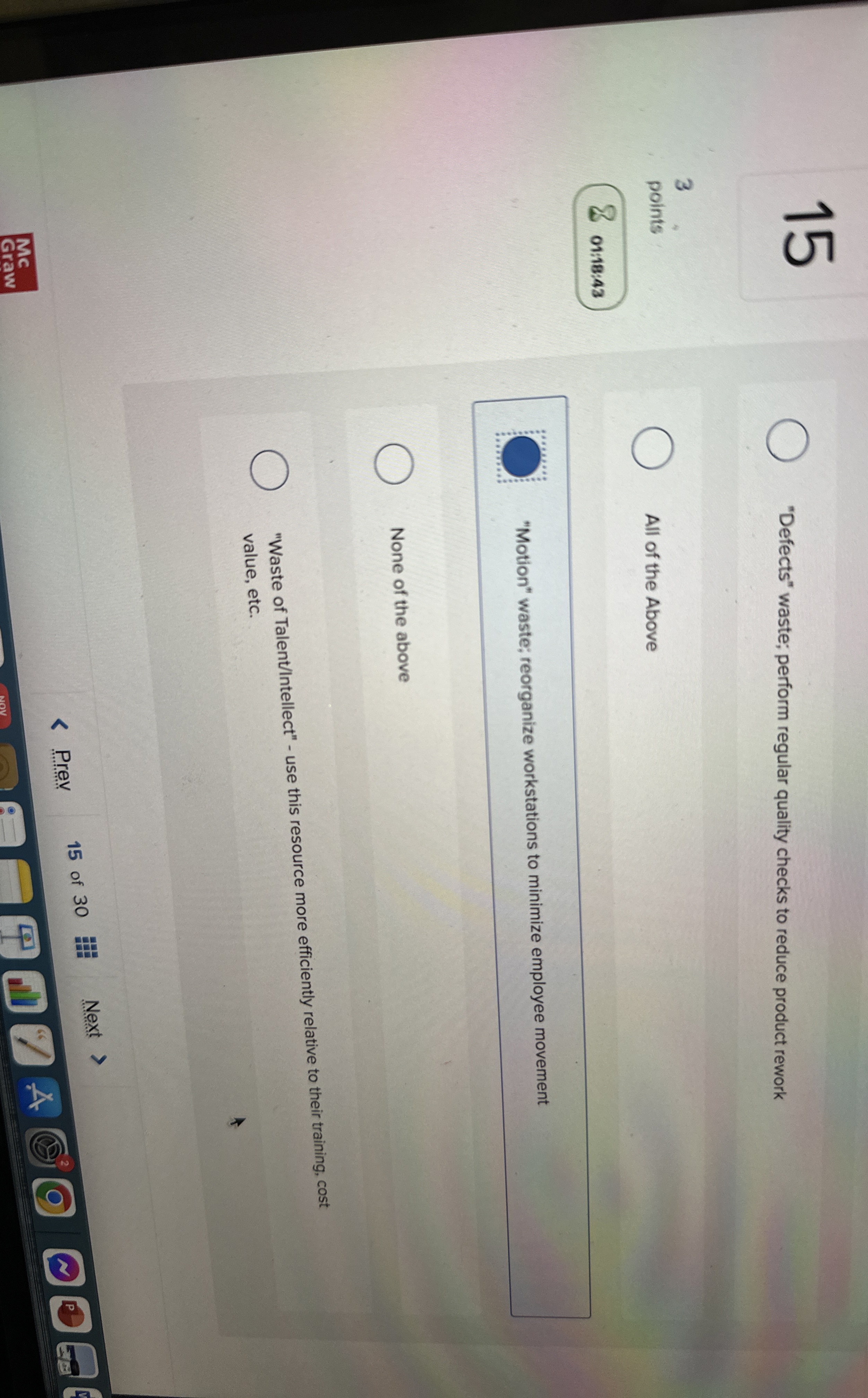

In a food processing facility, a supervisor notices that a worker frequently waits for the machine to be setup or adjusted before continuing their operating tasks. This often results in massive idle time, which disrupts workflow efficiency and delays downstream activities.

Which of the following describes the type of waste this scenario exemplifies, and what would be the most effective initial step to address this waste?

Multiple Choice

"Inventory" waste; reduce excess raw material storage to decrease idle time

"Defects" waste; perform regular quality checks to reduce product rework

All of the Above

Me

fraw

Prev

of

Next

"Defects" waste; perform regular quality checks to reduce product rework

points

::

All of the Above

"Motion" waste; reorganize workstations to minimize employee movement

None of the above

"Waste of TalentIntellect use this resource more efficiently relative to their training, cost value, etc.

Prev

of

Next

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock