Question: 1. A foundry has received an order for 20 custom-designed castings. The casting process costs $1,200 per unit. If a casting is not sold, it

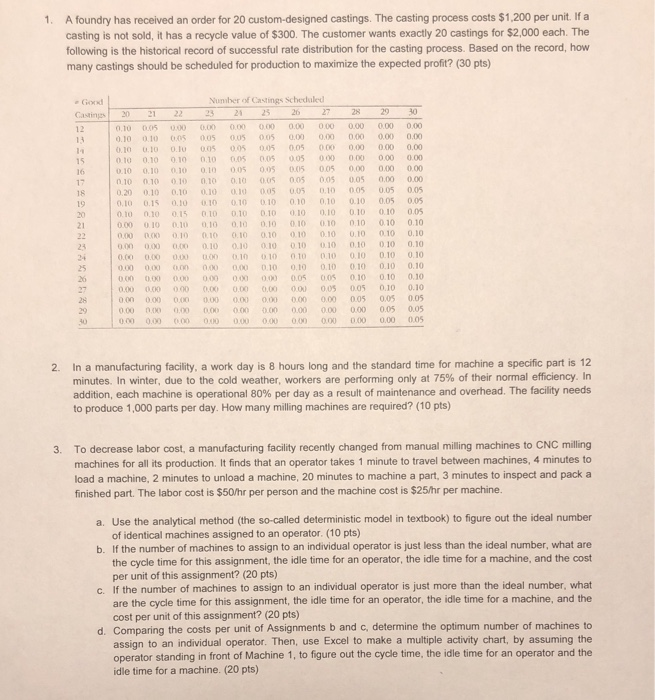

1. A foundry has received an order for 20 custom-designed castings. The casting process costs $1,200 per unit. If a casting is not sold, it has a recycle value of $300. The customer wants exactly 20 castings for $2,000 each. The following is the historical record of successful rate distribution for the casting process. Based on the record, how many castings should be scheduled for production to maximize the expected profit? (30 pts) Casting 20 21 22 100 01010 to 1 0.10 010 0.10 010 1 0 11.10 10 10 0.20 010 0.10 00015 0.00 0.10 0.15 10 0 0 10 0.00 0.00 0. 0000 0 0 0 00 0 0000 0 000 000 0 00 0 0 Number of Castings scheduled 23 24 25 26 27 28 29 30 0 000 000 000 000 000 0 00 000 000 000 0.00 0.00 00 000 000 000 000 0 0 00 00 00 0.00 0.00 0.00 010005 0.05 0.05 0.00 0.00 0.00 10 10 105 106 005 00 0.00 0.00 0.10 0 0 05 005 0.10 005 0.05 0.05 0 110010 010 0.10 0.05 0.05 010 010 0.10 0.10 0.10 0.10 0.10 0.05 0 00 00 00 010 10 10 10 10 10 10 0.10 100 100 100 100 100 100 10 0.10 0 0 1000 10010010 0.10 0 0.0 0.0 0.0 0.0 0.10 00 00 00 0.10 0.10 0000 00005 005 0.10 0.10 0 00 005 0.05 0.05 000 000 000 000 0.05 005 0 0 0 0 000 0.05 2. In a manufacturing facility, a work day is 8 hours long and the standard time for machine a specific part is 12 minutes. In winter, due to the cold weather, workers are performing only at 75% of their normal efficiency. In addition, each machine is operational 80% per day as a result of maintenance and overhead. The facility needs to produce 1,000 parts per day. How many milling machines are required? (10 pts) 3. To decrease labor cost, a manufacturing facility recently changed from manual milling machines to CNC milling machines for all its production. It finds that an operator takes 1 minute to travel between machines, 4 minutes to load a machine, 2 minutes to unload a machine, 20 minutes to machine a part, 3 minutes to inspect and pack a finished part. The labor cost is $50/hr per person and the machine cost is $25/hr per machine. a. Use the analytical method (the so-called deterministic model in textbook) to figure out the ideal number of identical machines assigned to an operator. (10 pts) b. If the number of machines to assign to an individual operator is just less than the ideal number, what are the cycle time for this assignment, the idle time for an operator, the idle time for a machine, and the cost per unit of this assignment? (20 pts) c. If the number of machines to assign to an individual operator is just more than the ideal number, what are the cycle time for this assignment, the idle time for an operator, the idle time for a machine, and the cost per unit of this assignment? (20 pts) d. Comparing the costs per unit of Assignments b and c, determine the optimum number of machines to assign to an individual operator. Then, use Excel to make a multiple activity chart, by assuming the operator standing in front of Machine 1, to figure out the cycle time, the idle time for an operator and the idle time for a machine. (20 pts) 1. A foundry has received an order for 20 custom-designed castings. The casting process costs $1,200 per unit. If a casting is not sold, it has a recycle value of $300. The customer wants exactly 20 castings for $2,000 each. The following is the historical record of successful rate distribution for the casting process. Based on the record, how many castings should be scheduled for production to maximize the expected profit? (30 pts) Casting 20 21 22 100 01010 to 1 0.10 010 0.10 010 1 0 11.10 10 10 0.20 010 0.10 00015 0.00 0.10 0.15 10 0 0 10 0.00 0.00 0. 0000 0 0 0 00 0 0000 0 000 000 0 00 0 0 Number of Castings scheduled 23 24 25 26 27 28 29 30 0 000 000 000 000 000 0 00 000 000 000 0.00 0.00 00 000 000 000 000 0 0 00 00 00 0.00 0.00 0.00 010005 0.05 0.05 0.00 0.00 0.00 10 10 105 106 005 00 0.00 0.00 0.10 0 0 05 005 0.10 005 0.05 0.05 0 110010 010 0.10 0.05 0.05 010 010 0.10 0.10 0.10 0.10 0.10 0.05 0 00 00 00 010 10 10 10 10 10 10 0.10 100 100 100 100 100 100 10 0.10 0 0 1000 10010010 0.10 0 0.0 0.0 0.0 0.0 0.10 00 00 00 0.10 0.10 0000 00005 005 0.10 0.10 0 00 005 0.05 0.05 000 000 000 000 0.05 005 0 0 0 0 000 0.05 2. In a manufacturing facility, a work day is 8 hours long and the standard time for machine a specific part is 12 minutes. In winter, due to the cold weather, workers are performing only at 75% of their normal efficiency. In addition, each machine is operational 80% per day as a result of maintenance and overhead. The facility needs to produce 1,000 parts per day. How many milling machines are required? (10 pts) 3. To decrease labor cost, a manufacturing facility recently changed from manual milling machines to CNC milling machines for all its production. It finds that an operator takes 1 minute to travel between machines, 4 minutes to load a machine, 2 minutes to unload a machine, 20 minutes to machine a part, 3 minutes to inspect and pack a finished part. The labor cost is $50/hr per person and the machine cost is $25/hr per machine. a. Use the analytical method (the so-called deterministic model in textbook) to figure out the ideal number of identical machines assigned to an operator. (10 pts) b. If the number of machines to assign to an individual operator is just less than the ideal number, what are the cycle time for this assignment, the idle time for an operator, the idle time for a machine, and the cost per unit of this assignment? (20 pts) c. If the number of machines to assign to an individual operator is just more than the ideal number, what are the cycle time for this assignment, the idle time for an operator, the idle time for a machine, and the cost per unit of this assignment? (20 pts) d. Comparing the costs per unit of Assignments b and c, determine the optimum number of machines to assign to an individual operator. Then, use Excel to make a multiple activity chart, by assuming the operator standing in front of Machine 1, to figure out the cycle time, the idle time for an operator and the idle time for a machine. (20 pts)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts