Question: 1.) Develop a forecast for Year 4 using the most appropriate method. 2.) Determine if seasonality is a meaningful factor and make appropriate adjustments if

1.) Develop a forecast for Year 4 using the most appropriate method.

1.) Develop a forecast for Year 4 using the most appropriate method.

2.) Determine if seasonality is a meaningful factor and make appropriate adjustments if warranted.

3.) Determine an Economic Order Quantity for Pharr's distributor.

4.) Using the seasonality factors, assess if it achieves service to its customers. If not, what adjustments can be made to ensure that customers have a supply of products on hand?

5.) Determine the Economic Order Quantities for each of the ingredients of the Far Stars candy, being sure to account for the quantity discounts offered by suppliers.

6.) Identify at least 5 issues that arise from the order policies of Pharr and its distributer have with regard to quality and supply chain management.

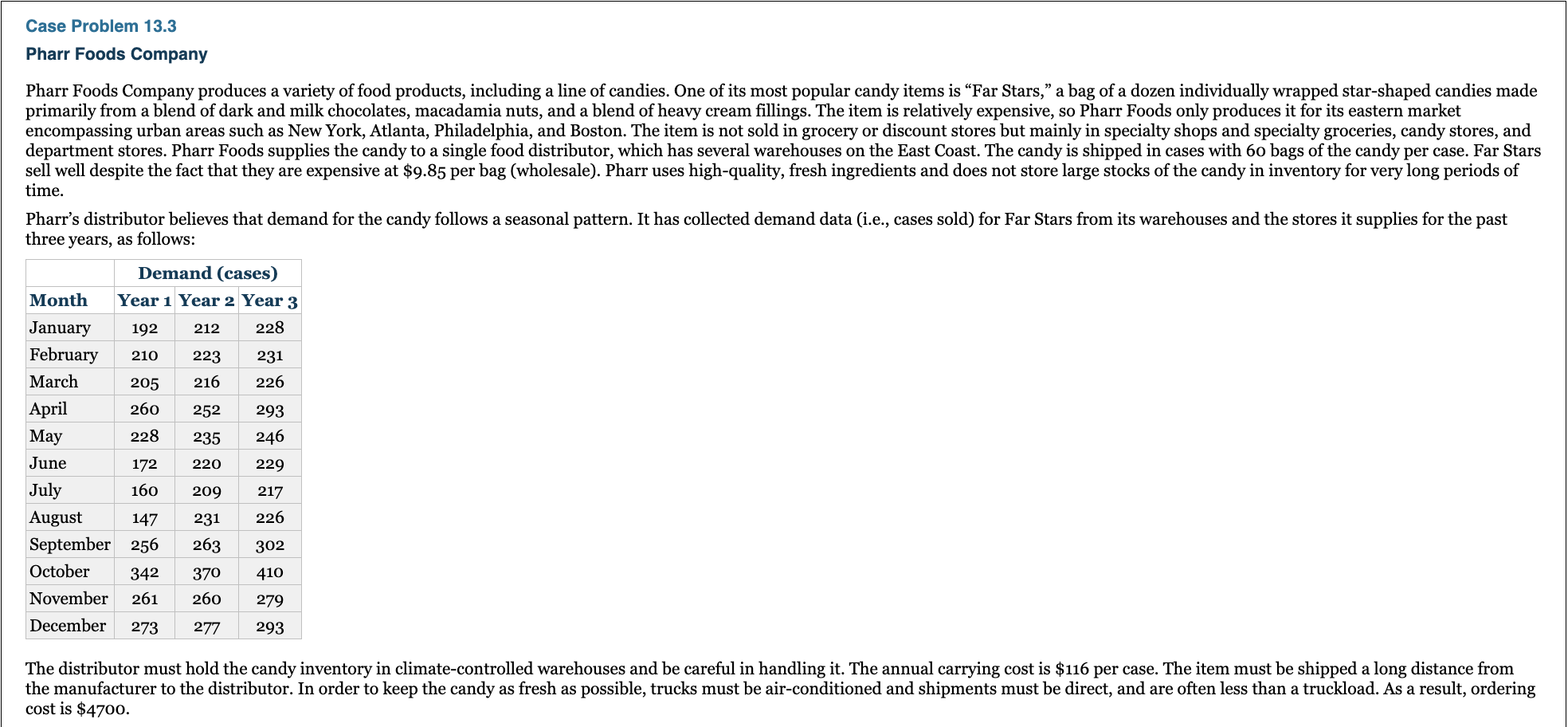

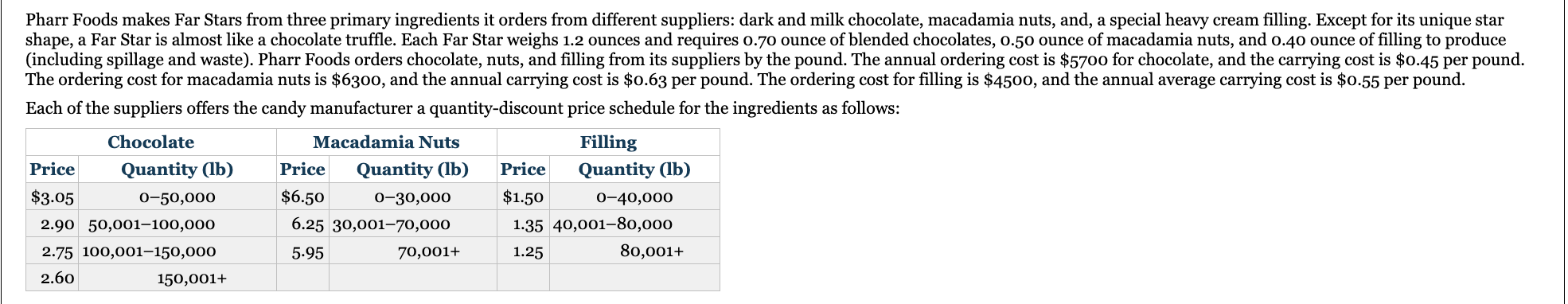

Pharr Foods Company Pharr Foods Company produces a variety of food products, including a line of candies. One of its most popular candy items is "Far Stars," a bag of a dozen individually wrapped star-shaped candies made primarily from a blend of dark and milk chocolates, macadamia nuts, and a blend of heavy cream fillings. The item is relatively expensive, so Pharr Foods only produces it for its eastern market encompassing urban areas such as New York, Atlanta, Philadelphia, and Boston. The item is not sold in grocery or discount stores but mainly in specialty shops and specialty groceries, candy stores, and department stores. Pharr Foods supplies the candy to a single food distributor, which has several warehouses on the East Coast. The candy is shipped in cases with 60 bags of the candy per case. Far Stars sell well despite the fact that they are expensive at $9.85 per bag (wholesale). Pharr uses high-quality, fresh ingredients and does not store large stocks of the candy in inventory for very long periods of time. Pharr's distributor believes that demand for the candy follows a seasonal pattern. It has collected demand data (i.e., cases sold) for Far Stars from its warehouses and the stores it supplies for the past three years, as follows: The distributor must hold the candy inventory in climate-controlled warehouses and be careful in handling it. The annual carrying cost is $116 per case. The item must be shipped a long distance from the manufacturer to the distributor. In order to keep the candy as fresh as possible, trucks must be air-conditioned and shipments must be direct, and are often less than a truckload. As a result, ordering cost is $4700. Pharr Foods makes Far Stars from three primary ingredients it orders from different suppliers: dark and milk chocolate, macadamia nuts, and, a special heavy cream filling. Except for its unique star shape, a Far Star is almost like a chocolate truffle. Each Far Star weighs 1.2 ounces and requires 0.70 ounce of blended chocolates, o.50 ounce of macadamia nuts, and o.40 ounce of filling to produce (including spillage and waste). Pharr Foods orders chocolate, nuts, and filling from its suppliers by the pound. The annual ordering cost is $5700 for chocolate, and the carrying cost is $0.45 per pound. The ordering cost for macadamia nuts is $6300, and the annual carrying cost is $0.63 per pound. The ordering cost for filling is $4500, and the annual average carrying cost is $0.55 per pound. Each of the suppliers offers the candy manufacturer a quantity-discount price schedule for the ingredients as follows

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts