Question: 1. Exercise problem 1.37 from Introduction to Chemical Processes: Principles, analysis and synthesis by Regina M. Murphy 2. Natural gas usually contains some H2S, a

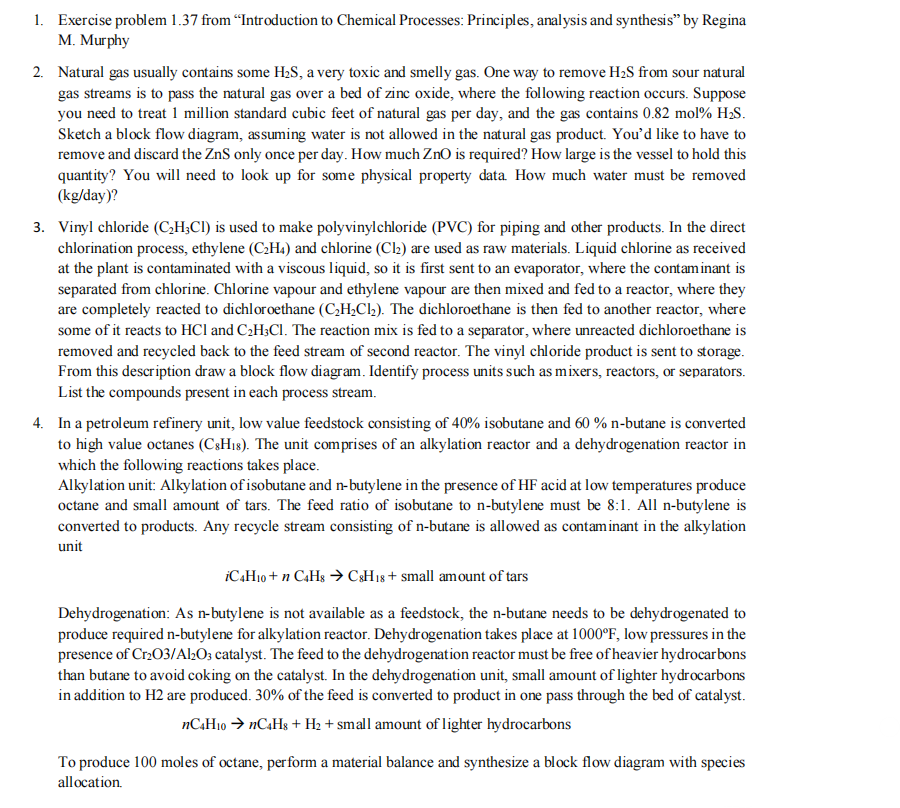

1. Exercise problem 1.37 from Introduction to Chemical Processes: Principles, analysis and synthesis by Regina M. Murphy 2. Natural gas usually contains some H2S, a very toxic and smelly gas. One way to remove H2S from sour natural gas streams is to pass the natural gas over a bed of zinc oxide, where the following reaction occurs. Suppose you need to treat 1 million standard cubic feet of natural gas per day, and the gas contains 0.82 mol% H2S. Sketch a block flow diagram, assuming water is not allowed in the natural gas product. You'd like to have to remove and discard the ZnS only once per day. How much ZnO is required? How large is the vessel to hold this quantity? You will need to look up for some physical property data. How much water must be removed (kg/day)? 3. Vinyl chloride (C_H_CI) is used to make polyvinylchloride (PVC) for piping and other products. In the direct chlorination process, ethylene (CH) and chlorine (Cl2) are used as raw materials. Liquid chlorine as received at the plant is contaminated with a viscous liquid, so it is first sent to an evaporator, where the contaminant is separated from chlorine. Chlorine vapour and ethylene vapour are then mixed and fed to a reactor, where they are completely reacted to dichloroethane (CH2Cl2). The dichloroethane is then fed to another reactor, where some of it reacts to HCl and C2H3C1. The reaction mix is fed to a separator, where unreacted dichloroethane is removed and recycled back to the feed stream of second reactor. The vinyl chloride product is sent to storage. From this description draw a block flow diagram. Identify process units such as mixers, reactors, or separators. List the compounds present in each process stream. 4. In a petroleum refinery unit, low value feedstock consisting of 40% isobutane and 60 % n-butane is converted to high value octanes (C3H18). The unit comprises of an alkylation reactor and a dehydrogenation reactor in which the following reactions takes place. Alkylation unit: Alkylation of isobutane and n-butylene in the presence of HF acid at low temperatures produce octane and small amount of tars. The feed ratio of isobutane to n-butylene must be 8:1. All n-butylene is converted to products. Any recycle stream consisting of n-butane is allowed as contaminant in the alkylation unit iC_H10 +n CHp CH18 + small amount of tars Dehydrogenation: As n-butylene is not available as a feedstock, the n-butane needs to be dehydrogenated to produce required n-butylene for alkylation reactor. Dehydrogenation takes place at 1000F, low pressures in the presence of Cr2O3/Al2O3 catalyst. The feed to the dehydrogenation reactor must be free of heavier hydrocarbons than butane to avoid coking on the catalyst. In the dehydrogenation unit, small amount of lighter hydrocarbons in addition to H2 are produced. 30% of the feed is converted to product in one pass through the bed of catalyst. nC.H10 CHp + H2 + small amount of lighter hydrocarbons a To produce 100 moles of octane, perform a material balance and synthesize a block flow diagram with species allocation

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts