Question: 1. Formulate DOFASCO's problem as an LP problem. State all your assumptions. DOFASCO - FUEL MANAGEMENT The Works Manager at Dominion Foundries and Steel (DOFASCO)

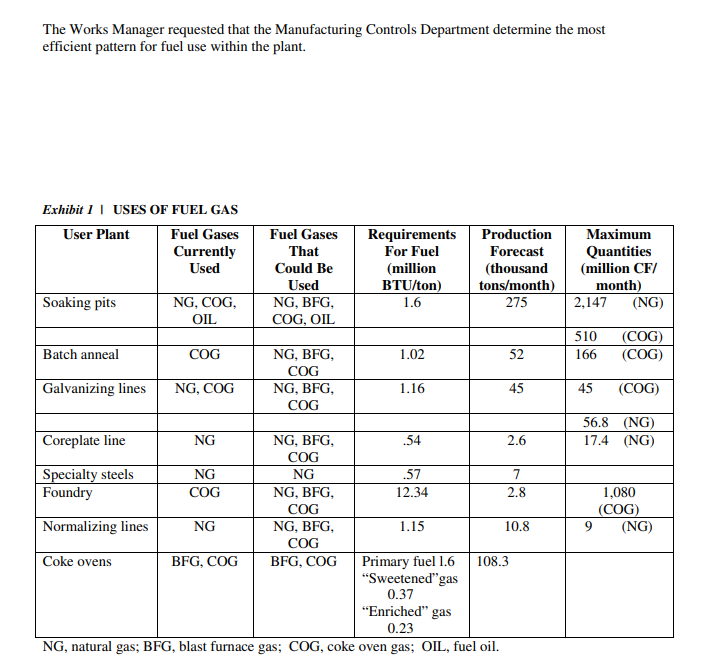

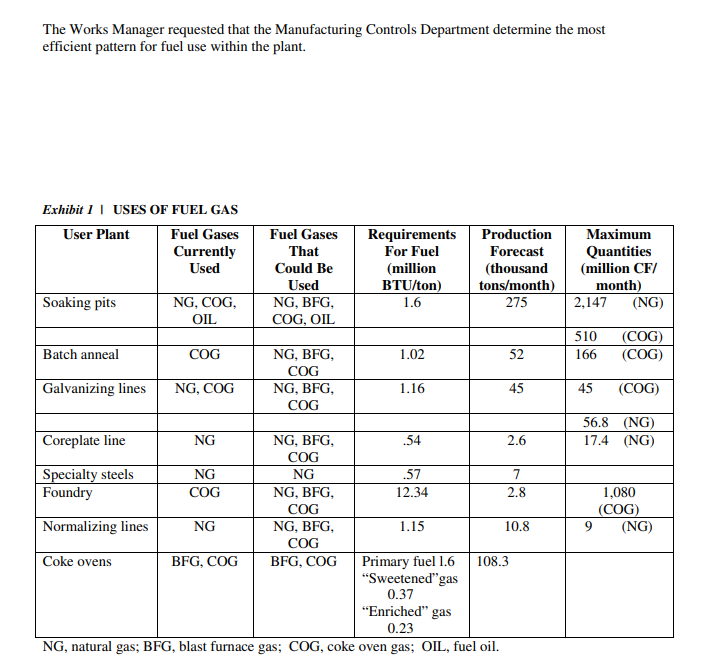

1. Formulate DOFASCO's problem as an LP problem. State all your assumptions. DOFASCO - FUEL MANAGEMENT The Works Manager at Dominion Foundries and Steel (DOFASCO) was faced with rapidly increasing market prices for fuel oil and natural gas. Anticipating that similar price increases were likely to continue for the foreseeable future, the Works Manager wanted to be certain that the steel works was making the best use of its energy dollars and, in particular, that the fuels produced as by products from plant operations were being efficiently used. THE COMPANY DOFASCO, founded in 1912, was an important steel producer that manufactured a variety of flat rolled steel products and castings. The company began as a foundry operation that supplied castings for the rail car manufacturing sector, but by the mid-1970s, it had grown into a fully integrated steel-making operation with over 10,000 employees. The company produced over 3 million ingot tons of steel and had annual sales of $621 million. Major production facilities located at its 700-acre plant included six coke oven batteries, four blast furnaces, two steel-making shops, a hot strip mill, and cold rolling and associated finishing lines. DOFASCO's product line included: Hot rolled sheet and strip - for automotive frames, wheels, and miscellaneous stampings, as well as construction and agricultural applications. Cold rolled sheet and strip - for automobile parts, appliances, metal containers, mechanical tubing, and agricultural equipment. Tin plate and chromium-coated steels - for food and beverage cans, crown, caps, and aerosol containers. Galvanized steel - for building and road construction, appliances, and automotive parts. Electrical steel - for transformers and motors Prepainted steel products - for building cladding, automobile parts, and miscellaneous end uses. Steel castings for railway components, gears, valves, and other industrial uses ENERGY SOURCES Fuel was produced within the plant from the blast furnaces and coke ovens. The blast furnaces produced 15,500 cubic feet (CF) of blast furnace gas (BFG) during production of each ton of iron. BFG had a low heat content (only 90 BTUs per CF), but because production was forecast at 3.3 million tons of iron, BFG represented a major energy source for DOFASCO. Furthermore, because BFG was an essential byproduct of blast furnace operation, the only cost associated with using BFG as a fuel gas was a cost of maintaining the BFG lines and necessary equipment. This cost was estimated at $5.00 per million CF used. Coke oven gas (COG) produced during coking by the coke ovens had a much higher BTU content than BFG (540 BTUs per CF), and each ton of coke produced was accompanied by the production of 12,000 CF at COG. Coke production was forecast at 1.3 million tons. The maintenance cost of the COG lines was estimated at $45.00 per million CF used. The fuel gas produced internally was augmented by natural gas and fuel oil purchased at market prices. Commercial fuel oil was currently available at $40 per 1,000 pounds and natural gas was available at $2,200 per 1,000,000 CF, although these prices were expected to increase dramatically in the future. One thousand pounds of fuel oil had a heat content of about 18.75 million BTUs, whereas natural gas produced 1,000 BTUs per CF. Maintenance costs for the natural gas lines were estimated at $0.10 per million CF, and those for the fuel oil lines at $8.00 per 1,000 pounds used. ENERGY REQUIREMENTS Production of steel was an energy-intensive process, consuming large quantities of electricity, coal, and fuel gas. There was considerable flexibility as to how the demands for fuel gas could be met from the available supplies. He coke ovens, annealing and finishing operations, and the foundry were major users of fuel gases. Each of these plants required a gas of a certain heat content (measured by BTU value) that could be made by combining different fuels. There were, however, restrictions on the amounts of some fuels that could be used to make up the BTUs necessary to produce 1 ton of steel by each process, which resulted from the physical characteristics of the process. Exhibit 1 summarizes the fuel gas requirements and restrictions for the eight major user plants. Coke ovens had somewhat different but strict requirements. There were three types of fuel used by the coke ovens: 1. Primary fuel (BFG), providing 1.6 million BTUs per ton. 2. Sweetened" gas, a mixture of BFG and COG averaging 100 BTUs per CF and providing 0.37 million BTUs per ton. 3. "Enriched gas, a mixture of BFG and COG averaging 250 BTUs per CF and providing 0.23 million BTUs per ton. The above three fuels, in combination, met the fuel requirement of 2.2 million BTUs per ton of coke produced DISTRIBUTION Although the actual flow of gas at the plant was complex and conditions, changed from hour to hour, the Works Manager decided to consider, for the purpose of long-run analysis, that the distribution of fuel gases in the steel works was limited only the requirements of the producer and user plants. If the analysis demonstrated that fuel costs could be reduced by improved allocation, then the necessary changes in equipment and operating rules could be implemented to effect this. The Works Manager requested that the Manufacturing Controls Department determine the most efficient pattern for fuel use within the plant. Exhibit 1 | USES OF FUEL GAS User Plant Fuel Gases Currently Used Fuel Gases That Could Be Used NG, BFG, COG, OIL Requirements For Fuel (million BTU/ton) 1.6 Production Forecast (thousand tons/month) 275 Maximum Quantities (million CF/ month) 2,147 (NG) Soaking pits NG, COG, OIL Batch anneal COG 1.02 52 510 166 (COG) (COG) NG, BFG, COG NG, BFG, COG Galvanizing lines NG, COG 1.16 45 45 (COG) 56.8 (NG) 17.4 (NG) .54 1,080 (COG) 9 (NG) Coreplate line NG NG, BFG, 2.6 COG Specialty steels NG NG .57 7 Foundry COG NG, BFG, 12.34 2.8 COG Normalizing lines NG NG, BFG, 1.15 10.8 COG Coke ovens BFG, COG BFG, COG Primary fuel 1.6 108.3 "Sweetened"gas 0.37 "Enriched" gas 0.23 NG, natural gas; BFG, blast furnace gas; COG, coke oven gas; OIL, fuel oil