Question: 1. identification issues 2. problem identification statement 3. devlope alternatives to address problem statement. 4. evaluate alternatives. Choose 1. 5. implement plan. 6. evaluate chosen

1. identification issues

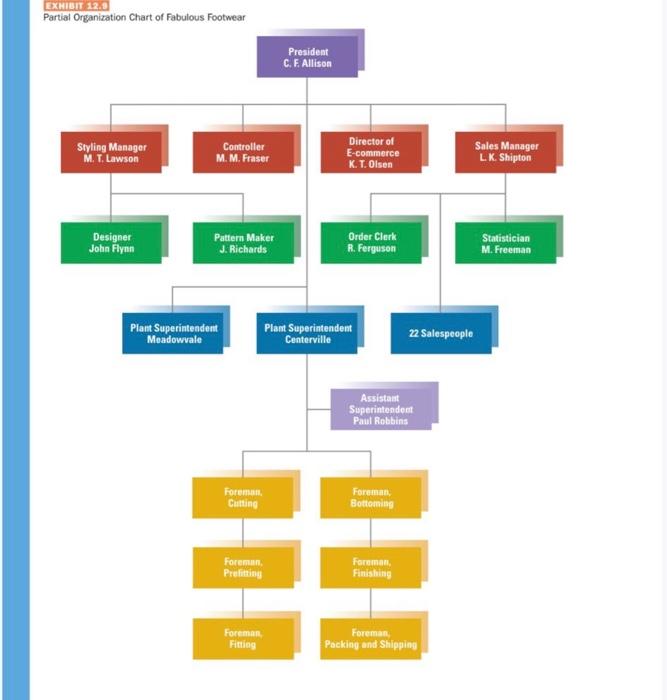

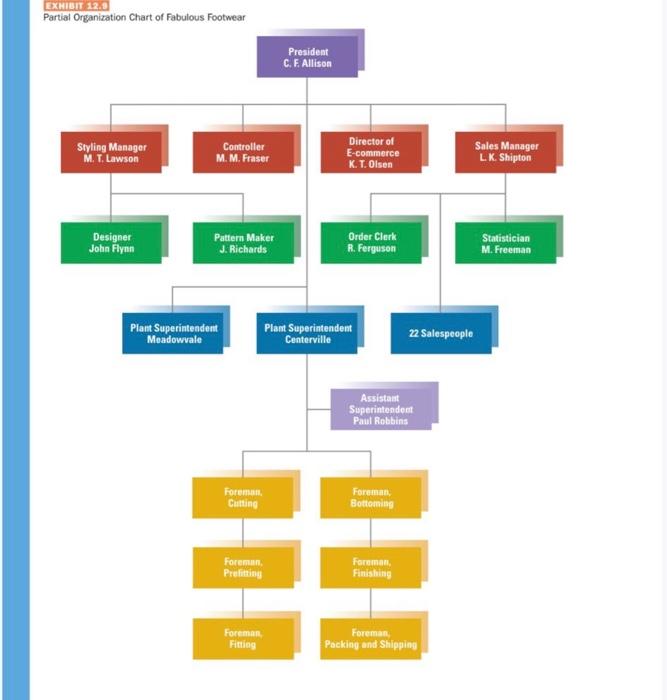

CASE FOR ANALYSIS Fabulous Footwear 139 Fabulous Footwear produces a line of women's shoes that advantage of the flexibility of a small organization to cre- sell in the lower-price market for $27.99 to $29.99 per ate designs that appeal to customers. Thus, demand can pair. Profits averaged 30 cents to 50 cents per pair 10 years be created and a price set high enough to make a profit. ago, but according to the president and the controller, Allison, incidentally, appears to have an artistic talent in labor and materials costs have risen so much in the inter styling and a record of successful judgments in approving vening period that profits today average only 25 cents to high-volume styles over the years. 30 cents per pair Regarding how Fabulous Footwear differs from its Production at both the company's plants totals 12,500 large competitors, Allison has said: pairs per day. The two factories are located within a radius You see, Brown and International Shoe Company both pro- of 60 miles of Chicago: one at Centerville, which produces duce hundreds of thousands of the same pair of shoes. They 4,500 pairs per day, and the other at Meadowvale, which produces 8,000 pairs per day. Company headquarters is store them in inventory at their factories. Their customers, the large wholesalers and retailers, simply know their line located in a building adjacent to the Centerville plant. It is difficult to give an accurate picture of the num as often as we do. Sometimes I wish we could do that, too. and send in orders. They do not have to change styles nearly ber of items in the company's product line. Shoes change it makes for a much more stable and orderly system. There in style perhaps more rapidly than any other style prod. is also less friction between people inside the company. The uct, including garments. This is chiefly because it is possi- historically, each company, in attempting to get ahead of sonnel are not shook up so often by someone coming in one ble to change production processes quickly and because, salespeople always know what they're selling: the produc- tion people know what is expected of them. The plant per competitors, gradually made style changes more frequently morning and tampering with their machine lines or their At present, including both major and minor style changes, schedules. The styling people are not shook up so often by Fabulous Footwear offers 100 to 120 different products to the plant saying, "We can't do your new style the way you customers each year. want it." A partial organizational chart, showing the depart- ments involved in this case, appears in Exhibit 12.9. To help Fabulous Footwear be more competitive against larger firms, Allison recently created an e-commerce and social media department. Although his main interest Competitive Structure of the was in marketing over the Internet, he also hoped new Industry technology would help reduce some of the internal fric- tion by giving people an easier way to communicate. He Very large general shoe houses, such as International and invested in sophisticated new information technology and Brown, carry a line of women's shoes and are able to hired consultants to set up a company intranet and pro- undercut prices charged by Fabulous Footwear, principally vide a few days' training to upper and middle managers. because of the policy in the big companies of producing Katherine Olsen came on board as director of e-commerce, large numbers of stable" shoes, such as the plain pump charged primarily with coordinating Internet marketing and the loafer . They do not attempt to change styles as rap and sales. When she took the job, she had visions of one idly as their smaller competitors. Thus, without constant day offering consumers the option of customized shoe changes in production processes and sales presentations, designs. However, Olsen was somewhat surprised to learn they are able to keep costs substantially lower. that most employees still refused to use the intranet even Charles E Allison, the president of Fabulous Footwear, for internal communication and coordination. The process feels that the only way for a small independent company for deciding on new styles, for example, had not changed to be competitive is to change styles frequently, taking since the 1980s. EXHIBIT 12.0 Partial Organization Chart of Fabulous Footwear President C. E Allison Styling Manager M. T. Lawson Controller M. M. Fraser Director of E-commerce K. T. Olsen Sales Manager LK. Shipton Designer John Flynn Pattern Maker J. Richards Order Clerk R. Ferguson Statistician M. Freeman Plant Superintendent Meadowvale Plant Superintendent Centerville 22 Salespeople Assistant Superintendent Paul Robbins Foreman. Cutting Foreman Bottoming Foreman Prefitting Foreman Finishing Foreman Fitting Foreman Packing and Shipping Chapter 12: Innovation and Change 517 Major Style Changes in process to the forman of the next department, the latter holds the inventory in storage and sends one pair each to The decision about whether to put a certain style into pro- Allison and Lawson. If they approve of the finished product, duction requires information from a number of different Allison instructs the shipping foreman to mail samples to people. Here is what typically happens in the company cach of the company's twenty-two salespeople throughout It may be helpful to follow the organization chart see the country. Olen also receives samples, photos, and draw Exhibit 12.9) tracing the procedure ings to post on the web page and gauge customer interest M.T. Lawson, the styling manager, and his designer, Salespeople have instructions to take the samples John Flynn, originate most of the ideas about shape, size of immediately within one week) to at least 10 customers. heel, use of flat sole or heels, and findings (the term used Orders for already established shoes are normally sent to for ornaments attached to, but not part of the shoes Ralph Ferguson, a clerk in Shipton's office, who records bows, straps, and so forth). They get their ideas principally them and forwards them to the plant superintendents for from reading style and trade magazines or by copying top production. However, salespeople have found by expe- flight designers. Lawson corresponds with publications rience that Martin Freeman has a greater interest in the and friends in large stores in New York, Rome, and Paris success of new trials, so they rush these orders to him to obtain pictures and samples of up-to-the-minute style by overnight mail, and he in turn places the first orders for innovations. Although he uses e-mail occasionally, Lawson a new style in the interoffice mail to the plant superinten prefers telephone contact and receiving drawings or sam dents. He then sends off a duplicate of the order, mailed in ples by overnight mail. Then, he and Flynn discuss various by the salespeople, to Ferguson for entering in his statisti ideas and come up with design options cal record of all orders received by the company When Lawson decides on a design, he takes a sketch Three weeks after the salespeople receive samples, to Allison, who either approves or disapproves it. If Allison Allison requires Ralph Ferguson to give him a tabulation approves, he (Allison) then passes the sketch on to L. K of orders. At that time, he decide whether the salespeople Shipton, the sales manager, to find out what lasts (widths) and the web page should push the item and the superinten should be chosen. Shipton, in turn, forwards the design dents should produce large quantities, or whether he will to Martin Freeman, a statistician in the sales department, tell them that although existing orders will be produced, who maintains summary information on customer demand the item will be discontinued in a short time. for colors and lasts According to Allison, the procedures outlined here To compile this information, Freeman visits salespeople have worked reasonably well. twice a year to get their opinions on the colors and lasts that the average time from where Lesen decides on a design are selling best, and he keeps records of shipments by color til we notify the Centerville plant to produce the palestrant is and by last. For these needs, he simply totals data that are nowwks to a month. Of course, if we could spend tutup sent to him by the shipping foreman in cach of the two plants. it would make the company jest that much more secure When Freeman has decided on the lasts and colors, he sends Allison a form that lists the colors and lasts in which was away from our competitors. There seems to be endless staying in the game against the big commies, and in taking the shoe should be produced. Allison, if he approves this list, forwards the information to Lawson, who puts it please of the business. That's to be expand where you have brackering among people around here more in the styling on to Jenna Richards, an expert pattern maker. Richards to mow there ich im to stop and one all makes a paper pattern and then constructs a prototype in of the social mesties. I have thote that a formal a leather and paper. She sends this to Lawson, who in turn approves or disapproves it. He forwards any approved wisation dat would be good in this company's prototype to Allison. Allison, if he, too, approves, notifies turked out a castomary system here that fonctions well Lawson, who takes the prototype to Paul Robbins, assis M.T. Lawson, manager of styling, said that within his tant to the superintendent of the Centerville plant. Oaly department all work seems to get out in minimum time, he this plant produces small quantities of new or experimen also stated that both Flynn and Richards are good employ, tal shne styles. This is referred to as a "pilot run" by exec ces and skilled in their work. He mentioned that Hymn had utives at the plant been in to see him twice in the last year: Robbins then literally carries the prototype through to inquire about Iris !Hy future in the company. Hea the six production departments of the plant-from cutting 33 years old and has three children. I know that he is eager to finishing-discusing it with cach foreman, who in turn to make money, and I assured from that ouer the years we works with employees on the machines in having a sam- ple lot of several thousand paits made. When the finished can raise bant raght along from the $65,000 we are lot is delivered by the finishing foreman to the shipping playing. Actually, he has learned a lot about shoe styles since we hired home from se design department of a fabric foreman because of the importance of styling, Allison has directed that each foreman personally deliver styling goods company six years ago 518 Part : Managing Dynamie Processes John Flynn revealed The result of a second, similar project (Y) was put into I was actually becoming dissatisfied with this jobAll side production the next year, but this time sales were discon compumes copy styles-it's a generally accepted practice tinued after three weeks within the industry. But the picked up a real feel for de siges, and evral times we sted that the com make all its own original styles. We could make Fabulous Problem Between Lawson and Footavara style leader and also increase ourse. Wh Robbins I ask Lawson about thes, he says it takes too much time for Frequently, perhaps 10 to 12 times a year, disagreement the designer to create original--hut we have all we can handle to do research in trade magazines and maintain.com arisies between Mel Lawson, manager of styling, and Paul Practs feeding as the results of experti. Besides, he says Robbins, assistant to the superintendent of the Centerville styles are standing the test of the marketplace. plant. Robbins and The styling people don't understand what it means to pro- duce a short the quantities that we do, and to make the Projects X and Y changes in production that we have to. They dream up leicht out of the air. They do not realise that we Flynn also said that he and Martin Freeman had frequently have a lot of machines that has to be adjusted and that talked about the styling problem. They felt that: some shops they dramp take much longer or a Allison is really a great president, and the company sure machines thorolers, thus creating a bottleneck in the hy would be lost without him. However, we've seen times production line. If they put a bow or strap on position weben be lost a lot of money on bud judgments in styles, Norther than other, it muy more to keep people Unti-perlaps sx or se times in the last eighteen die or later machines while there is a pileup on the sete months. Also, he is of cows, extremely busy as presidenting machines on which this complicated little operation is of the corporation. He must look after rything from performed. This cost the plant money. Purthermore, there cing from the banks to burgaining with the nion. The are times when they get the prototype here late, and either read that he is sometimes nailable to do this styling the former and I work overtime or the trial run wont get approval for several days. or een two weeks. In a times through in time to a new production SON Hewstyles, like this, the kind of delay can cost money. It also makes to take the plant capacity liberated by our stopping pre him slightly edgx It tends, at times where be any other doctor or old styles. Les doesn't know much about things to do, to make her look quickly at the style web production and sales and the whole company. I thank all le mit, or the prototypes Richards mukes, or the finished does is to bring shoes down here to the plant, sort of like shoes that are sent for approval by the shippung foreman memperboy Why should be be solurd to get along Sometimes I worry that he makro kinds of errors. He ? He's getting paid any more than I am, and wory simply rubber stamps www done, which makes send position in the plant is just as portant ass. ing these things to manaste of time. At the times makes snap judgments of his outling those of ting along with Robbins Lawson, in turn, said that he has a difficult time get who have spent so much time and expertise on the shoe. We do think he has good judgment, but hemel has said There are times when Robbe is just able 1 ar ties that he wishes he had more time to concentrate tabe prototypes to him for times a month and other styling and approval of prototypes and final products. minor style changes to be six or eight times I tell him y time that we have problem s gring these ready Flynn further explained and this was corroborated by but he knows only about the plant and telling me does Freeman that the two had worked out two plans, which set to do wygood. We first joined the company, w they referred to a "project and project in the first go along all right , but he has gotten burder and burder to Flynn created an original design that was not copied from get along with existing styles. Freeman then gave special attention to color and last research for the shoe and recommended a color line that didn't exactly fit past recorda ce consumer Other Problems purchaser-but one he and Flynn thought would have great consumer appeal." This design and color recom Ralph Ferguson, the clerk in the sales department who mendation was accepted by Lawson and Allison the shoe receives orders from salespeople and forwards totals for went into production and was one of the three top sellers production schedules to the two plant superintendents, has during the calendar year. The latter women did not know complained that the salespeople and Freeman are bypassing that the shoe was styled in a different way from the al him in their practice of ending experimental shoc order to procedure Freeman. He insisted that his job description one of only 519 Chapter 12: Innovation and Change two written descriptions in the company) gives him respon approached Charles Allison several times about the need sibility for receiving all orders throughout the company and to make greater use of the expensive and sophisticated for maintaining historical statistics on shipments. computer information systems he had installed. Although Both the salespeople and Freeman, on the other hand, Allison always agrees with her, he has so far done nothing said that before they started the new practice that is when to help solve the problem. Olsen thinks the new technol- Ferguson still received the experimental shoe orders), ogy could dramatically improve coordination at Fabulous there were at least 8 or 10 instances a year when these Footwear were delayed from 1 to 3 days on Ferguson's desk. They Everyone needs to be working from the same data at reported that Ferguson just wasn't interested in new styles. the same time. As soon as Lawson and Flynn come up so the salespeople just started sending them to Freeman." with a new design, it should be posted on the intranet Ferguson acknowledged that there were times of short so all of us can be informed. And everyone needs ao delay, but said that there were good reasons for them cess to sales and order information, production sched- They (the salespeople and Freeman) are so interested in mles, and shipping deadlines. If everyone--from Allison new designs, colors, and lasts that they can't understand down to the people in the production plants-was kept the importance of a systematic handling of the whole order up to date throughout the entire process, we wouldn't procedure, including both old and new shoe styles. There have all this confusion and bickering. But no one around must be accuracy. Sure, I give some priority to experimen here wants to give up any control-they all have their tal orders, but sometimes when rush orders for existing own little operations and don't want to share informa company products are piling mp, and when there's a lot tion with anyone else. For example. I sometimes don't of planning I have to do to allocate production between even know there's a new style in the works until I get Centerville and Meadowvale, I decide which comes first finished samples and photos. No one seems to recognize processing of these, or processing the experimental shoe that one of the biggest advantages of the Internet is to orders. Shipron is my boss, nor the salespeople or Freeman. help stay ahead of changing styles. I know that Flyon has I'm going to insist that these orders come to me. 4 good feel for design, and we're not taking advantage of his abilities. But I also have information and ideas that could belp this company keep pace with changes and re- The Push for New Technology ally stand out from the crowd. I don't know how long we expect to remain competitive using this cumbersome, Katherine Olsen believes many of these problems could slow-moving process and putting out shoes that are al be solved through better use of technology. She has ready behind the times. CASE FOR ANALYSIS Fabulous Footwear 139 Fabulous Footwear produces a line of women's shoes that advantage of the flexibility of a small organization to cre- sell in the lower-price market for $27.99 to $29.99 per ate designs that appeal to customers. Thus, demand can pair. Profits averaged 30 cents to 50 cents per pair 10 years be created and a price set high enough to make a profit. ago, but according to the president and the controller, Allison, incidentally, appears to have an artistic talent in labor and materials costs have risen so much in the inter styling and a record of successful judgments in approving vening period that profits today average only 25 cents to high-volume styles over the years. 30 cents per pair Regarding how Fabulous Footwear differs from its Production at both the company's plants totals 12,500 large competitors, Allison has said: pairs per day. The two factories are located within a radius You see, Brown and International Shoe Company both pro- of 60 miles of Chicago: one at Centerville, which produces duce hundreds of thousands of the same pair of shoes. They 4,500 pairs per day, and the other at Meadowvale, which produces 8,000 pairs per day. Company headquarters is store them in inventory at their factories. Their customers, the large wholesalers and retailers, simply know their line located in a building adjacent to the Centerville plant. It is difficult to give an accurate picture of the num as often as we do. Sometimes I wish we could do that, too. and send in orders. They do not have to change styles nearly ber of items in the company's product line. Shoes change it makes for a much more stable and orderly system. There in style perhaps more rapidly than any other style prod. is also less friction between people inside the company. The uct, including garments. This is chiefly because it is possi- historically, each company, in attempting to get ahead of sonnel are not shook up so often by someone coming in one ble to change production processes quickly and because, salespeople always know what they're selling: the produc- tion people know what is expected of them. The plant per competitors, gradually made style changes more frequently morning and tampering with their machine lines or their At present, including both major and minor style changes, schedules. The styling people are not shook up so often by Fabulous Footwear offers 100 to 120 different products to the plant saying, "We can't do your new style the way you customers each year. want it." A partial organizational chart, showing the depart- ments involved in this case, appears in Exhibit 12.9. To help Fabulous Footwear be more competitive against larger firms, Allison recently created an e-commerce and social media department. Although his main interest Competitive Structure of the was in marketing over the Internet, he also hoped new Industry technology would help reduce some of the internal fric- tion by giving people an easier way to communicate. He Very large general shoe houses, such as International and invested in sophisticated new information technology and Brown, carry a line of women's shoes and are able to hired consultants to set up a company intranet and pro- undercut prices charged by Fabulous Footwear, principally vide a few days' training to upper and middle managers. because of the policy in the big companies of producing Katherine Olsen came on board as director of e-commerce, large numbers of stable" shoes, such as the plain pump charged primarily with coordinating Internet marketing and the loafer . They do not attempt to change styles as rap and sales. When she took the job, she had visions of one idly as their smaller competitors. Thus, without constant day offering consumers the option of customized shoe changes in production processes and sales presentations, designs. However, Olsen was somewhat surprised to learn they are able to keep costs substantially lower. that most employees still refused to use the intranet even Charles E Allison, the president of Fabulous Footwear, for internal communication and coordination. The process feels that the only way for a small independent company for deciding on new styles, for example, had not changed to be competitive is to change styles frequently, taking since the 1980s. EXHIBIT 12.0 Partial Organization Chart of Fabulous Footwear President C. E Allison Styling Manager M. T. Lawson Controller M. M. Fraser Director of E-commerce K. T. Olsen Sales Manager LK. Shipton Designer John Flynn Pattern Maker J. Richards Order Clerk R. Ferguson Statistician M. Freeman Plant Superintendent Meadowvale Plant Superintendent Centerville 22 Salespeople Assistant Superintendent Paul Robbins Foreman. Cutting Foreman Bottoming Foreman Prefitting Foreman Finishing Foreman Fitting Foreman Packing and Shipping Chapter 12: Innovation and Change 517 Major Style Changes in process to the forman of the next department, the latter holds the inventory in storage and sends one pair each to The decision about whether to put a certain style into pro- Allison and Lawson. If they approve of the finished product, duction requires information from a number of different Allison instructs the shipping foreman to mail samples to people. Here is what typically happens in the company cach of the company's twenty-two salespeople throughout It may be helpful to follow the organization chart see the country. Olen also receives samples, photos, and draw Exhibit 12.9) tracing the procedure ings to post on the web page and gauge customer interest M.T. Lawson, the styling manager, and his designer, Salespeople have instructions to take the samples John Flynn, originate most of the ideas about shape, size of immediately within one week) to at least 10 customers. heel, use of flat sole or heels, and findings (the term used Orders for already established shoes are normally sent to for ornaments attached to, but not part of the shoes Ralph Ferguson, a clerk in Shipton's office, who records bows, straps, and so forth). They get their ideas principally them and forwards them to the plant superintendents for from reading style and trade magazines or by copying top production. However, salespeople have found by expe- flight designers. Lawson corresponds with publications rience that Martin Freeman has a greater interest in the and friends in large stores in New York, Rome, and Paris success of new trials, so they rush these orders to him to obtain pictures and samples of up-to-the-minute style by overnight mail, and he in turn places the first orders for innovations. Although he uses e-mail occasionally, Lawson a new style in the interoffice mail to the plant superinten prefers telephone contact and receiving drawings or sam dents. He then sends off a duplicate of the order, mailed in ples by overnight mail. Then, he and Flynn discuss various by the salespeople, to Ferguson for entering in his statisti ideas and come up with design options cal record of all orders received by the company When Lawson decides on a design, he takes a sketch Three weeks after the salespeople receive samples, to Allison, who either approves or disapproves it. If Allison Allison requires Ralph Ferguson to give him a tabulation approves, he (Allison) then passes the sketch on to L. K of orders. At that time, he decide whether the salespeople Shipton, the sales manager, to find out what lasts (widths) and the web page should push the item and the superinten should be chosen. Shipton, in turn, forwards the design dents should produce large quantities, or whether he will to Martin Freeman, a statistician in the sales department, tell them that although existing orders will be produced, who maintains summary information on customer demand the item will be discontinued in a short time. for colors and lasts According to Allison, the procedures outlined here To compile this information, Freeman visits salespeople have worked reasonably well. twice a year to get their opinions on the colors and lasts that the average time from where Lesen decides on a design are selling best, and he keeps records of shipments by color til we notify the Centerville plant to produce the palestrant is and by last. For these needs, he simply totals data that are nowwks to a month. Of course, if we could spend tutup sent to him by the shipping foreman in cach of the two plants. it would make the company jest that much more secure When Freeman has decided on the lasts and colors, he sends Allison a form that lists the colors and lasts in which was away from our competitors. There seems to be endless staying in the game against the big commies, and in taking the shoe should be produced. Allison, if he approves this list, forwards the information to Lawson, who puts it please of the business. That's to be expand where you have brackering among people around here more in the styling on to Jenna Richards, an expert pattern maker. Richards to mow there ich im to stop and one all makes a paper pattern and then constructs a prototype in of the social mesties. I have thote that a formal a leather and paper. She sends this to Lawson, who in turn approves or disapproves it. He forwards any approved wisation dat would be good in this company's prototype to Allison. Allison, if he, too, approves, notifies turked out a castomary system here that fonctions well Lawson, who takes the prototype to Paul Robbins, assis M.T. Lawson, manager of styling, said that within his tant to the superintendent of the Centerville plant. Oaly department all work seems to get out in minimum time, he this plant produces small quantities of new or experimen also stated that both Flynn and Richards are good employ, tal shne styles. This is referred to as a "pilot run" by exec ces and skilled in their work. He mentioned that Hymn had utives at the plant been in to see him twice in the last year: Robbins then literally carries the prototype through to inquire about Iris !Hy future in the company. Hea the six production departments of the plant-from cutting 33 years old and has three children. I know that he is eager to finishing-discusing it with cach foreman, who in turn to make money, and I assured from that ouer the years we works with employees on the machines in having a sam- ple lot of several thousand paits made. When the finished can raise bant raght along from the $65,000 we are lot is delivered by the finishing foreman to the shipping playing. Actually, he has learned a lot about shoe styles since we hired home from se design department of a fabric foreman because of the importance of styling, Allison has directed that each foreman personally deliver styling goods company six years ago 518 Part : Managing Dynamie Processes John Flynn revealed The result of a second, similar project (Y) was put into I was actually becoming dissatisfied with this jobAll side production the next year, but this time sales were discon compumes copy styles-it's a generally accepted practice tinued after three weeks within the industry. But the picked up a real feel for de siges, and evral times we sted that the com make all its own original styles. We could make Fabulous Problem Between Lawson and Footavara style leader and also increase ourse. Wh Robbins I ask Lawson about thes, he says it takes too much time for Frequently, perhaps 10 to 12 times a year, disagreement the designer to create original--hut we have all we can handle to do research in trade magazines and maintain.com arisies between Mel Lawson, manager of styling, and Paul Practs feeding as the results of experti. Besides, he says Robbins, assistant to the superintendent of the Centerville styles are standing the test of the marketplace. plant. Robbins and The styling people don't understand what it means to pro- duce a short the quantities that we do, and to make the Projects X and Y changes in production that we have to. They dream up leicht out of the air. They do not realise that we Flynn also said that he and Martin Freeman had frequently have a lot of machines that has to be adjusted and that talked about the styling problem. They felt that: some shops they dramp take much longer or a Allison is really a great president, and the company sure machines thorolers, thus creating a bottleneck in the hy would be lost without him. However, we've seen times production line. If they put a bow or strap on position weben be lost a lot of money on bud judgments in styles, Norther than other, it muy more to keep people Unti-perlaps sx or se times in the last eighteen die or later machines while there is a pileup on the sete months. Also, he is of cows, extremely busy as presidenting machines on which this complicated little operation is of the corporation. He must look after rything from performed. This cost the plant money. Purthermore, there cing from the banks to burgaining with the nion. The are times when they get the prototype here late, and either read that he is sometimes nailable to do this styling the former and I work overtime or the trial run wont get approval for several days. or een two weeks. In a times through in time to a new production SON Hewstyles, like this, the kind of delay can cost money. It also makes to take the plant capacity liberated by our stopping pre him slightly edgx It tends, at times where be any other doctor or old styles. Les doesn't know much about things to do, to make her look quickly at the style web production and sales and the whole company. I thank all le mit, or the prototypes Richards mukes, or the finished does is to bring shoes down here to the plant, sort of like shoes that are sent for approval by the shippung foreman memperboy Why should be be solurd to get along Sometimes I worry that he makro kinds of errors. He ? He's getting paid any more than I am, and wory simply rubber stamps www done, which makes send position in the plant is just as portant ass. ing these things to manaste of time. At the times makes snap judgments of his outling those of ting along with Robbins Lawson, in turn, said that he has a difficult time get who have spent so much time and expertise on the shoe. We do think he has good judgment, but hemel has said There are times when Robbe is just able 1 ar ties that he wishes he had more time to concentrate tabe prototypes to him for times a month and other styling and approval of prototypes and final products. minor style changes to be six or eight times I tell him y time that we have problem s gring these ready Flynn further explained and this was corroborated by but he knows only about the plant and telling me does Freeman that the two had worked out two plans, which set to do wygood. We first joined the company, w they referred to a "project and project in the first go along all right , but he has gotten burder and burder to Flynn created an original design that was not copied from get along with existing styles. Freeman then gave special attention to color and last research for the shoe and recommended a color line that didn't exactly fit past recorda ce consumer Other Problems purchaser-but one he and Flynn thought would have great consumer appeal." This design and color recom Ralph Ferguson, the clerk in the sales department who mendation was accepted by Lawson and Allison the shoe receives orders from salespeople and forwards totals for went into production and was one of the three top sellers production schedules to the two plant superintendents, has during the calendar year. The latter women did not know complained that the salespeople and Freeman are bypassing that the shoe was styled in a different way from the al him in their practice of ending experimental shoc order to procedure Freeman. He insisted that his job description one of only 519 Chapter 12: Innovation and Change two written descriptions in the company) gives him respon approached Charles Allison several times about the need sibility for receiving all orders throughout the company and to make greater use of the expensive and sophisticated for maintaining historical statistics on shipments. computer information systems he had installed. Although Both the salespeople and Freeman, on the other hand, Allison always agrees with her, he has so far done nothing said that before they started the new practice that is when to help solve the problem. Olsen thinks the new technol- Ferguson still received the experimental shoe orders), ogy could dramatically improve coordination at Fabulous there were at least 8 or 10 instances a year when these Footwear were delayed from 1 to 3 days on Ferguson's desk. They Everyone needs to be working from the same data at reported that Ferguson just wasn't interested in new styles. the same time. As soon as Lawson and Flynn come up so the salespeople just started sending them to Freeman." with a new design, it should be posted on the intranet Ferguson acknowledged that there were times of short so all of us can be informed. And everyone needs ao delay, but said that there were good reasons for them cess to sales and order information, production sched- They (the salespeople and Freeman) are so interested in mles, and shipping deadlines. If everyone--from Allison new designs, colors, and lasts that they can't understand down to the people in the production plants-was kept the importance of a systematic handling of the whole order up to date throughout the entire process, we wouldn't procedure, including both old and new shoe styles. There have all this confusion and bickering. But no one around must be accuracy. Sure, I give some priority to experimen here wants to give up any control-they all have their tal orders, but sometimes when rush orders for existing own little operations and don't want to share informa company products are piling mp, and when there's a lot tion with anyone else. For example. I sometimes don't of planning I have to do to allocate production between even know there's a new style in the works until I get Centerville and Meadowvale, I decide which comes first finished samples and photos. No one seems to recognize processing of these, or processing the experimental shoe that one of the biggest advantages of the Internet is to orders. Shipron is my boss, nor the salespeople or Freeman. help stay ahead of changing styles. I know that Flyon has I'm going to insist that these orders come to me. 4 good feel for design, and we're not taking advantage of his abilities. But I also have information and ideas that could belp this company keep pace with changes and re- The Push for New Technology ally stand out from the crowd. I don't know how long we expect to remain competitive using this cumbersome, Katherine Olsen believes many of these problems could slow-moving process and putting out shoes that are al be solved through better use of technology. She has ready behind the times 2. problem identification statement

3. devlope alternatives to address problem statement.

4. evaluate alternatives. Choose 1.

5. implement plan.

6. evaluate chosen alternative

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock