Question: 1 . Regional distributors are currently using continuous review inventory policy. Compute and describe their inventory management policy and associated cost. Ignore inbound and outbound

Regional distributors are currently using continuous review inventory policy. Compute and describe their inventory management policy and associated cost. Ignore inbound and outbound transportation cost. Provide answers and calculations for order quantity, demand during lead time, safety stock, average inventory level, inventory holding cost per week, ordering cost per week, and total cost per week.

Q Ddlt SS Avg Inv Inv cost Ord Cost Tot Cost

Atlanta

Boston

Chicago

Dallas

LA

Total cost of the distribution system

Demand and Inventory Management Strategy

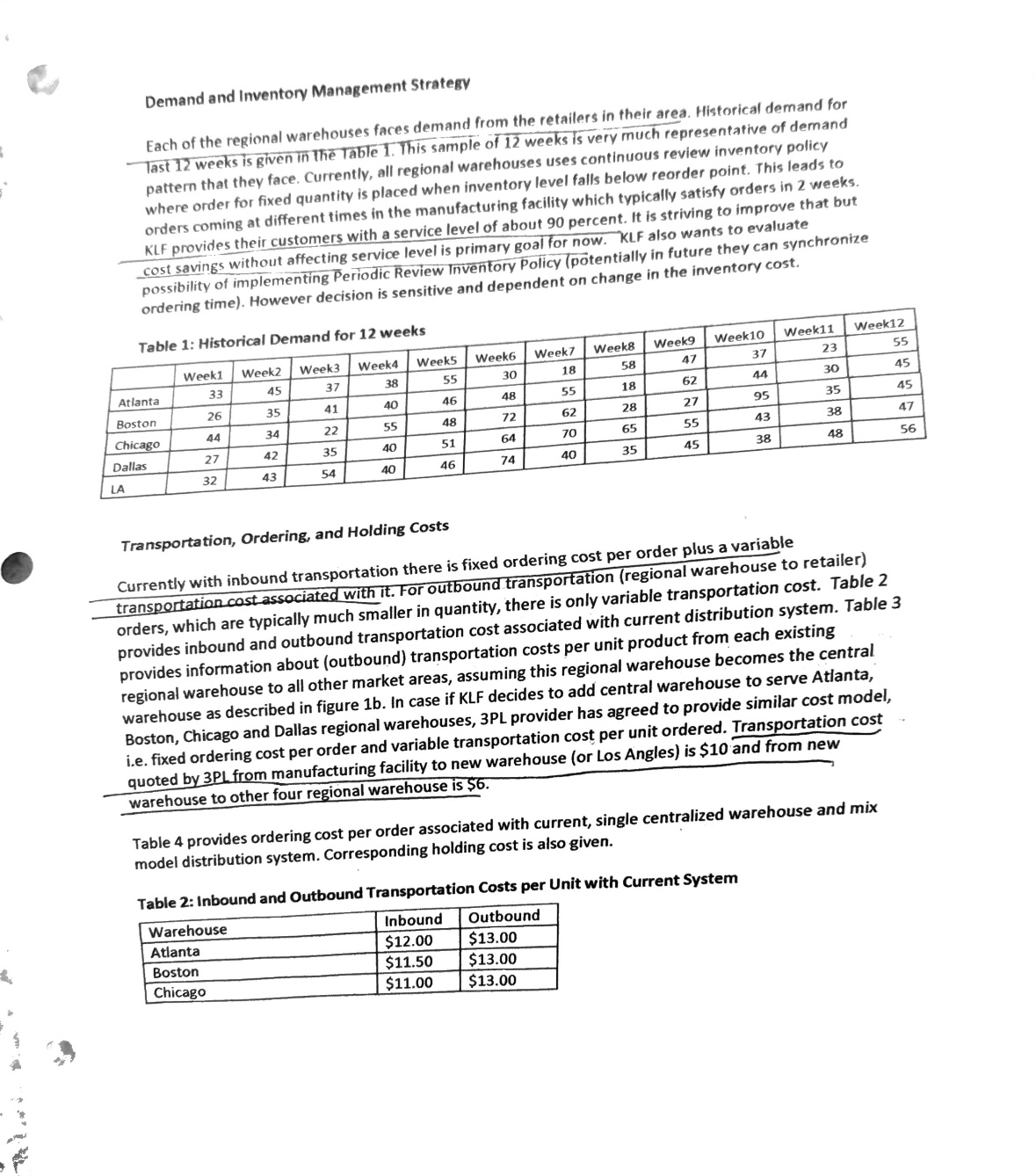

Each of the regional warehouses faces demand from the retailers in their area. Historical demand for

last weeks is given in the Table This sample of weeks is very much representative of demand

pattern that they face. Currently, all regional warehouses uses continuous review inventory policy

where order for fixed quantity is placed when inventory level falls below reorder point. This leads to

orders coming at different times in the manufacturing facility which typically satisfy orders in weeks.

KLF provides their customers with a service level of about percent. It is striving to improve that but

cost savings without affecting service level is primary goal for now. KLF also wants to evaluate

possibility of implementing Periodic Review Inventory Policy potentially in future they can synchronize

ordering time However decision is sensitive and dependent on change in the inventory cost.

Table : Historical Demand for weeks

Transportation, Ordering, and Holding Costs

Currently with inbound transportation there is fixed ordering cost per order plus a variable

transpertation costassociated with it For outbound the is only variable transportation

orders, which are typically much smaller in quantion cost associated with current distribution system

provides information about outbound transpors assuming this regional warehouse becomes the central

regional warehouse to all other market areas, KLF decides to add central warehouse to serve Atlanta,

warehouse as described in figure In case

Boston, Chicago and Dallas regional warehable transportation cost per unit ordered. Transportation cost

ie fixed ordering cost per order and variab to new warehouse or Los Angles is $ and from new

quoted by PL from manufacturing facility

Table provides ordering cost per order associated with current, single centralized warehouse and mix

model distribution system. Corresponding holding cost is also given.

Table : Inbound and Outbound Transportation Costs per Unit with Current System

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock