Question: 1. This question is about Machining: Describe the process plan for the machining of (1) the top flat surface (overall final-part desired dimensions: 30

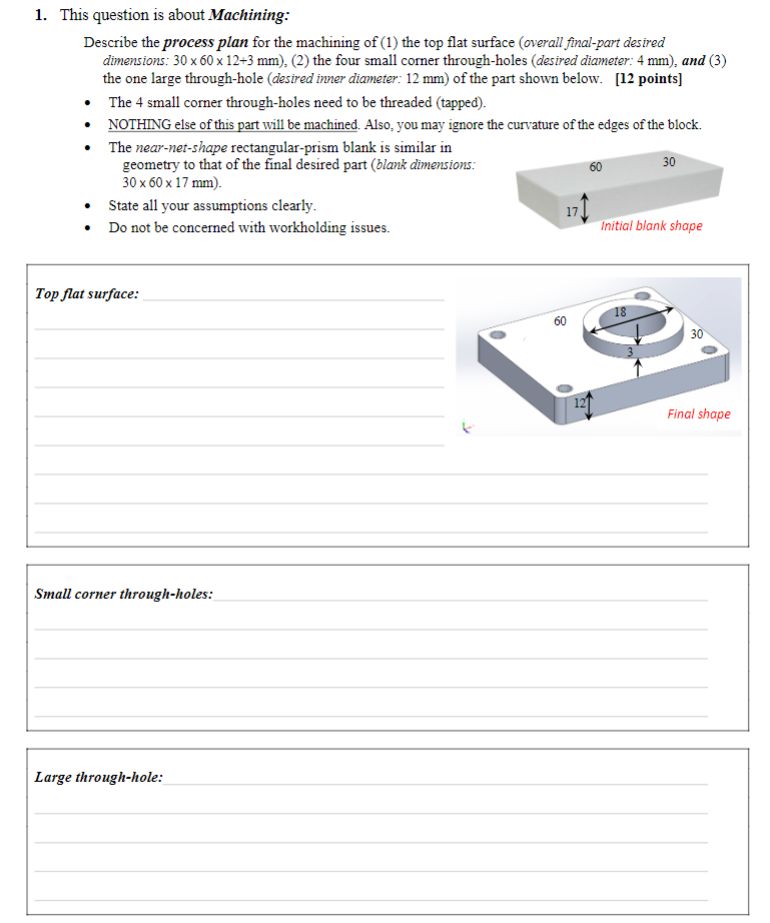

1. This question is about Machining: Describe the process plan for the machining of (1) the top flat surface (overall final-part desired dimensions: 30 x 60 x 12+3 mm), (2) the four small corner through-holes (desired diameter: 4 mm), and (3) the one large through-hole (desired inner diameter: 12 mm) of the part shown below. [12 points] The 4 small corner through-holes need to be threaded (tapped). NOTHING else of this part will be machined. Also, you may ignore the curvature of the edges of the block. The near-net-shape rectangular-prism blank is similar in geometry to that of the final desired part (blank dimensions: 30 x 60 x 17 mm). State all your assumptions clearly. Do not be concerned with workholding issues. 60 30 Initial blank shape Top flat surface: Small corner through-holes: Large through-hole: 18 60 30 Final shape

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts