Question: 1. Using a decision tree based on maximizing expected profit, decide which machine Toledo Leather should select. Should overtime be scheduled? Or should machine be

1. Using a decision tree based on maximizing expected profit, decide which machine Toledo Leather should select. Should overtime be scheduled? Or should machine be modified and, if so, under what circumstances? 2. Set up a payoff matrix for the sales volumes given (assume the machines cannot be modified and overtime is used), and assume that the probabilities for the five levels of sales are not known. Then decide which machine should be purchase using the maximax criterion, the maximin criterion, and the equally likely criterion.

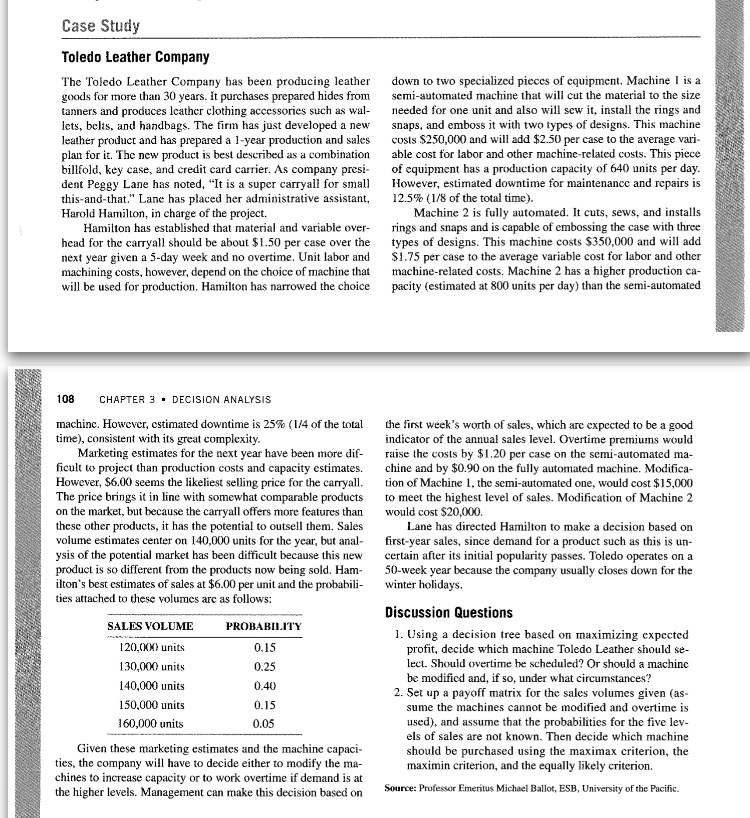

Case Study Toledo Leather Company The Toledo Leather Company has been producing leather goods for more than 30 years. It purchases prepared hides from tanners and produces .cather clothing accessories such as wal- lets, belts, and handbags. The firm has just developed a new leather product and has prepared a 1-year production and sales plan for it. The new product is best described as a combination billfold, key case, and credit card carrier. As company presi- dent Peggy Lane has noted, "It is a super carryall for small this-and-that." Lane has placed her administrative assistant, Harold Hamilton, in charge of the project. Hamilton has established that material and variable over- head for the carryall should be about $1.50 per case over the next year given a 5-day week and no overtime. Unit labor and machining costs, however, depend on the choice of machine that will be used for production. Hamilton has narrowed the choice down to two specialized pieces of equipment. Machine 1 is a semi-automated machine that will cut the material to the size needed for one unit and also will sew it, install the rings and snaps, and emboss it with two types of designs. This machine costs $250,000 and will add $2.50 per case to the average vari- able cost for labor and other machine-related costs. This piece of equipment has a production capacity of 640 units per day. However, estimated downtime for maintenance and repairs is 12.5% (1/8 of the total time). Machine 2 is fully automated. It cuts, sews, and installs rings and snaps and is capable of embossing the case with three types of designs. This machine costs $350,000 and will add $1.75 per case to the average variable cost for labor and other machine-related costs. Machine 2 has a higher production ca- pacity (estimated at 800 units per day) than the semi-automated 108 CHAPTER 3. DECISION ANALYSIS machinc. However, estimated downtime is 25% (1/4 of the total the first week's worth of sales, which are expected to be a good time), consistent with its great complexity. indicator of the annual sales level. Overtime premiums would Marketing estimates for the next year have been more dif- raise the costs by $1.20 per case on the semi-automated ma- ficult to project than production costs and capacity estimates. chine and by $0.90 on the fully automated machine. Modifica- However, $6.00 seems the likeliest selling price for the carryall. tion of Machine 1, the semi-automated one, would cost $15,000 The price brings it in line with somewhat comparable products to meet the highest level of sales. Modification of Machine 2 on the market, but because the carryall offers more features than would cost $20,000 these other products, it has the potential to outsell them. Sales Lane has directed Hamilton to make a decision based on volume estimates center on 140,000 units for the year, but anal first-year sales, since demand for a product such as this is un- ysis of the potential market has been difficult because this new certain after its initial popularity passes. Toledo operates on a product is so different from the products now being sold. Ham 50-week year because the company usually closes down for the ilton's best estimates of sales at $6.00 per unit and the probabili- winter holidays. ties attached to these volumes are as follows: Discussion Questions SALES VOLUME PROBABILITY 1. Using a decision tree based on maximizing expected 120,000 units 0.15 profit, decide which machine Toledo Leather should se- 130,000 units 0.25 lect. Should overtime he scheduled? Or should a machine be modified and, if so, under what circumstances? 140,000 units 0.40 2. Set up a payoff matrix for the sales volumes given (as- 150,000 units 0.15 sume the machines cannot be modified and overtime is 160,000 units 0.05 used), and assume that the probabilities for the five lev- els of sales are not known. Then decide which machine Given these marketing estimates and the machine capaci should be purchased using the maximax criterion, the ties, the company will have to decide either to modify the ma maximin criterion, and the equally likely criterion. chines to increase capacity or to work overtime if demand is at the higher levels. Management can make this decision based on Source: Professor Emeritus Michael Ballot, ESB, University of the PacificStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts