Question: 1.) Using the critical ratio rule, establish the priority for the eight jobs. 2.)Use a gant chart to load the operation according to the priority

1.) Using the critical ratio rule, establish the priority for the eight jobs.

2.)Use a gant chart to load the operation according to the priority rule established. In other words, load the most important job in all three work centers, then the next most important, and so forth. This is the method that John used.

3.) Analyze John's approach and try to determine if he has a problem, andif he does determine the source of the problem.

4.) Try to provide a long-term solution, i.e., a solution which will potentially work beyond the current set of jobs.

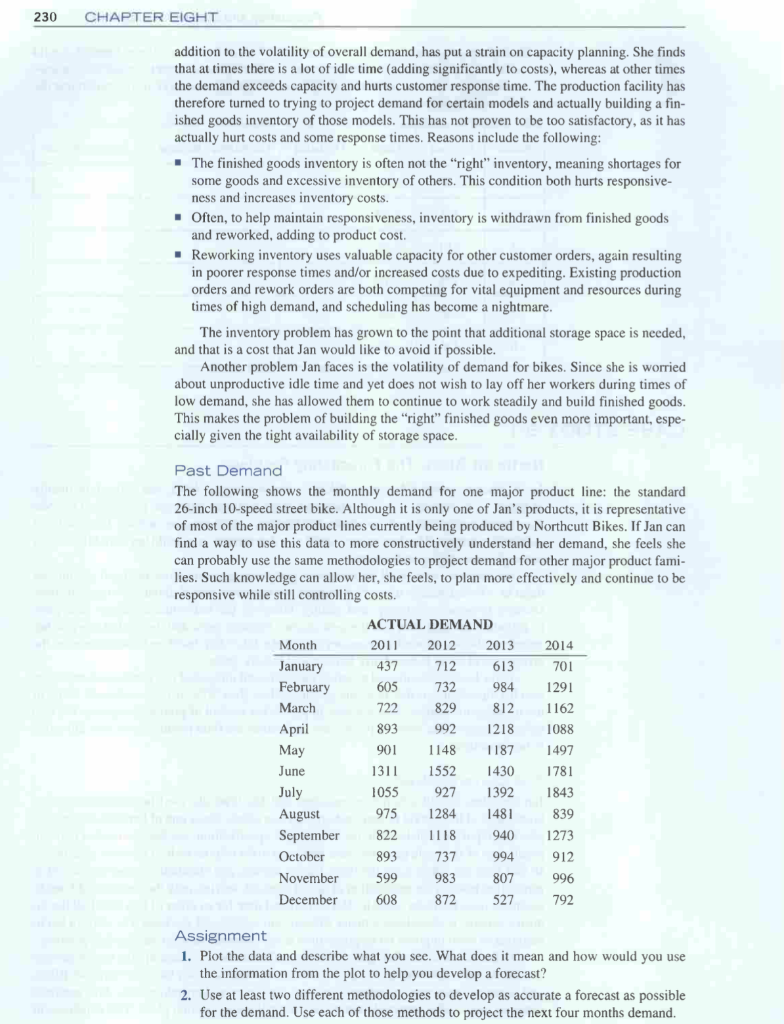

addition to the volatility of overall demand, has put a strain on capacity planning. She finds that at times there is a lot of idle time (adding significantly to costs), whereas at other times the demand exceeds capacity and hurts customer response time. The production facility has therefore turned to trying to project demand for certain models and actually building a finished goods inventory of those models. This has not proven to be too satisfactory, as it has actually hurt costs and some response times. Reasons include the following: The finished goods inventory is often not the "right" inventory, meaning shortages for some goods and excessive inventory of others. This condition both hurts responsiveness and increases inventory costs. - Often, to help maintain responsiveness, inventory is withdrawn from finished goods and reworked, adding to product cost. - Reworking inventory uses valuable capacity for other customer orders, again resulting in poorer response times and/or increased costs due to expediting. Existing production orders and rework orders are both competing for vital equipment and resources during times of high demand, and scheduling has become a nightmare. The inventory problem has grown to the point that additional storage space is needed, and that is a cost that Jan would like to avoid if possible. Another problem Jan faces is the volatility of demand for bikes. Since she is worried about unproductive idle time and yet does not wish to lay off her workers during times of low demand, she has allowed them to continue to work steadily and build finished goods. This makes the problem of building the "right" finished goods even more important, especially given the tight availability of storage space. Past Demand The following shows the monthly demand for one major product line: the standard 26-inch 10 -speed street bike. Although it is only one of Jan's products, it is representative of most of the major product lines currently being produced by Northcutt Bikes. If Jan can find a way to use this data to more constructively understand her demand, she feels she can probably use the same methodologies to project demand for other major product families. Such knowledge can allow her, she feels, to plan more effectively and continue to be responsive while still controlling costs. Assignment 1. Plot the data and describe what you see. What does it mean and how would you use the information from the plot to help you develop a forecast? 2. Use at least two different methodologies to develop as accurate a forecast as possible for the demand. Use each of those methods to project the next four months demand. 3. Which method from question 2 is "better"? How do you know thatStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts