Question: 1 Warehouse Order Picking Optimization A warehouse processes orders with the following tasks, their times, and dependencies: Additional Information The warehouse needs to process 6

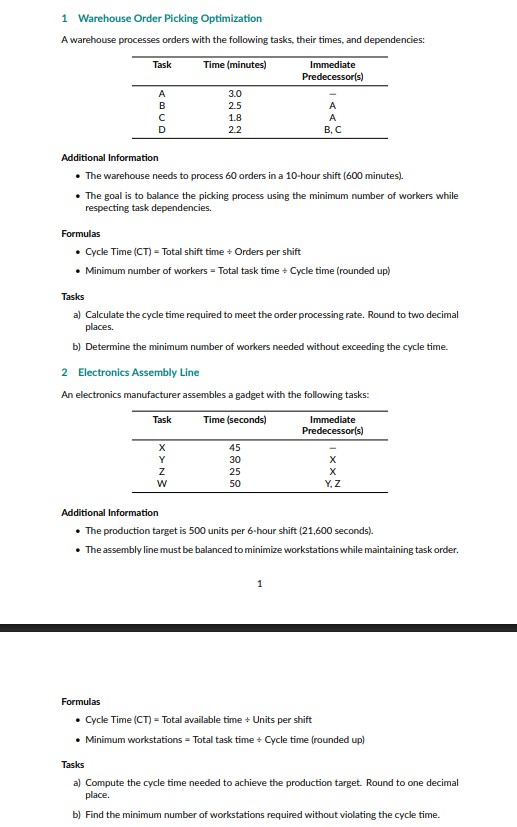

Warehouse Order Picking Optimization

A warehouse processes orders with the following tasks, their times, and dependencies:

Additional Information

The warehouse needs to process orders in a hour shift minutes

The goal is to balance the picking process using the minimum number of workers while

respecting task dependencies.

Formulas

Cycle Time CT Total shift time : Orders per shift

Minimum number of workers Total task time : Cycle time rounded up

Tasks

a Calculate the cycle time required to meet the order processing rate. Round to two decimal

places.

b Determine the minimum number of workers needed without exceeding the cycle time.

Electronics Assembly Line

An electronics manufacturer assembles a gadget with the following tasks:

Additional Information

The production target is units per hour shift seconds

The assembly line must be balanced to minimize workstations while maintaining task order.

Formulas

Cycle Time CT Total available time : Units per shift

Minimum workstations Total task time : Cycle time rounded up

Tasks

a Compute the cycle time needed to achieve the production target. Round to one decimal

place.

b Find the minimum number of workstations required without violating the cycle time.

A bakery produces cakes with the following tasks and dependencies:

Additional Information

The bakery aims to produce cakes during a hour shift minutes

The goal is to balance the production line with the fewest workstations possible.

Formulas

Cycle Time CT Total shift time : Cakes per shift

Minimum workstations Total task time Cycle time rounded up

Tasks

a Determine the cycle time required for the production goal. Round to two decimal places.

b Calculate the minimum number of workstations needed to stay within the cycle time.

Automotive Parts Assembly

An automotive supplier assembles a component with the following tasks:

Additional Information

The target is to assemble components in an hour shift minutes

The assembly process must be optimized to use the minimum number of stations.

Formulas

Cycle Time CT Available shift time : Components per shift

Minimum stations Total task time Cycle time rounded up

Tasks

a Calculate the cycle time needed to meet the production target. Round to two decimal

places.

b Determine the minimum number of stations required without exceeding the cycle time.

Furniture Manufacturing Line

A furniture company builds chairs with the following tasks:

Additional Information

The goal is to produce chairs in a hour shift minutes

The production line must be balanced to minimize workstations while respecting task or

der.

Formulas

Cycle Time CT Total shift time : Chairs per shift

Minimum workstations Total task time : Cycle time rounded up

Tasks

a Compute the cycle time required to achieve the production rate. Round to two decimal

places.

b Find the minimum number of workstations needed without violating the cycle time.

Packaging Line Optimization

A packag

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock