Question: 11. How would you characterize the most important difference for the following issues when comparing a job shop and a flow shop? 12. The diagram

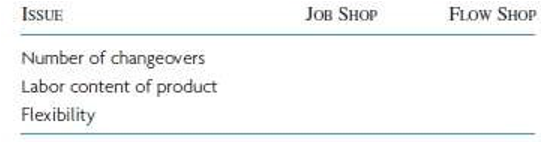

11. How would you characterize the most important difference for the following issues when comparing a job shop and a flow shop?

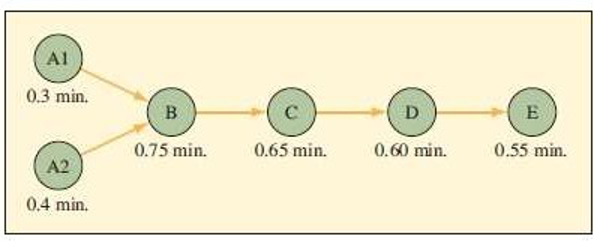

12. The diagram below represents a process where two components are made at stations A1 and A2 (one component is made at A1 and the other at A2). These components are then assembled at station B and moved through the rest of the process, where some additional work is completed at stations C, D, and E.

Assume that one and only one person is allowed at each station. Assume that the times given below for each station represent the amount of work that needs to be done at that station by that person, with no processing time variation. Assume that inventory is not allowed to build in the system.

- What is the average hourly output of the process when it is in normal operation?

13. A certain custom engraving shop has traditionally had orders for between 1 and 50 units of whatever a customer orders. A large company has contacted this shop about engraving reward plaques (which are essentially identical to each other). It wants the shop to place a bid for this order. The volume is expected to be 12,000 units per year and will most likely last four years.

- To successfully bid (low enough price) for such an order, what will the shop likely have to do?

14. The productprocess matrix is a convenient way of characterizing the relationship between product volumes (one-of-a-kind to continuous) and the processing system employed by a firm at a particular location. In the boxes presented below, describe the nature of the intersection between the type of shop (column) and process dimension (row).

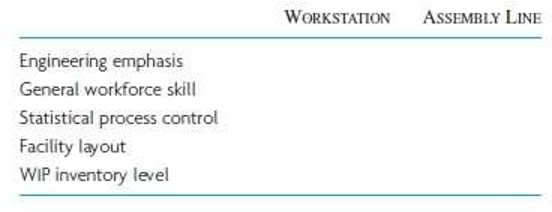

15. For each of the following variables, explain the differences (in general) as one moves from a workstation to an assembly line environment.

a. Throughput time (time to convert raw material into product).

b. Capital/labor intensity.

c. Bottlenecks.

A1 0.3min. B 0.75min. D 0.60min. E 0.55min. A2 0.65min. C. 0.4min. \begin{tabular}{l} WORKSTATION ASSEMBLY LINE \\ \hline Engineering emphasis \\ General workforce skill \\ Statistical process control \\ Facility layout \\ WIP inventory level \\ \hline \end{tabular}

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts