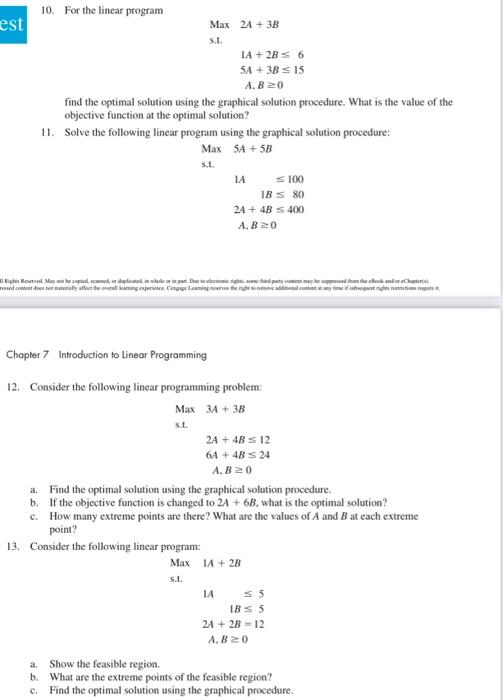

Question: 1For the linear program Max 2A 1 3B s.t. 1A12B# 6 5A 1 3B # 15 SELF test A, B $ 0 find the optimal

1For the linear program

Max 2A 1 3B s.t.

1A12B# 6

5A 1 3B # 15

SELF

test

A, B $ 0

find the optimal solution using the graphical solution procedure. what is the value of the

objective function at the optimal solution?

2 . Consider the following linear program:

Max 1A 1 2B s.t.

1A #5 1B# 5 2A 1 2B 512

A, B $ 0

a.show the feasible region .

b. what are the extreme points of the feasible region?

c. Find the optimal solution using the graphical procedure.

A semiconductor technically refers to the material, usu- ally silicon, used to build integrated circuits that become the main building components for electronic devices. But in casual usage, semiconductor manufacturing refers to the design and production of the actual integrated circuit that performs the calculations necessary to power your computers, smartphones, tablets, and virtually every other electronic device with which you are familiar.

Semiconductor supply chains are very complex be- cause they typically stretch across the globe and include many different suppliers, manufacturers, distributors, and customers. Hundreds of operations are required to produce semiconductors, and lead times are often very long. To produce a finished semiconductor, the three- dimensional circuits must be deposited onto the base layer of semiconductive material through a process of deposition, photolithography, etching, and ion implan- tation. The circuits must then be thoroughly tested and packaged for shipment to customers. Small deviations in the manufacturing process result in different quality (speed) of devices. These different devices can some- times be used as a substitute in times of shortages. For instance, if there are no medium-speed devices avail- able for a certain manufacturing step, a high-speed de- vice can be used instead, but a medium-speed device cannot be substituted for a high-speed device. This

*Based on Alfred Degbotse, Brian t. Denton, Kenneth Fordyce, R. John Milne, Robert orzell, Chi-tai Wang, IBM Blends Heuristics and optimization to Plan Its Semiconductor Supply Chain, Interfaces, 2012, 112.

creates a multitude of different possible flows through the supply chain that must be constantly managed.

IBM has been producing semiconductors for more than 50 years. IBM manufactures semiconductors in Asia and in North America, and they distribute them around the world. IBM has been using quantitative methods for many years to plan and execute its supply chain strategies. IBMs Central Planning Engine (CPE) is the set of tools the company uses to manage its supply chain activities for semiconductors. The CPE uses a combination of quantita- tive methods, including linear programming. The model constraints include limitations on production capacities, raw material availabilities, lead time delays, and demand requirements. There are also constraints to enforce the substitution possibilities for certain devices. while many different problem-solving methods are used in the CPE, linear programing is used in several different steps, in- cluding the allocation of production capacity to devices based on available capacities and materials.

IBM uses the CPE to perform both long-term stra- tegic planning and short-term operational execution for its semiconductor supply chain. Because of the clever use of specific quantitative methods, these complex cal- culations can be completed in just a few hours. These fast solution times allow IBM to run several different possible scenarios in a single day and implement sen- sitivity analysis to understand possible risks in its sup- ply chain. IBM credits the use of the CPE to increasing on-time deliveries by 15% and reducing inventory by 25 to 30%.

question 10 and 13 please .

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock