Question: 1.Prepare an aggregate plan for the coming year, assuming that the sales forecast is perfect. Use the spreadsheet Bradford Manufacturing. In the spreadsheet, an area

1.Prepare an aggregate plan for the coming year, assuming that the sales forecast is perfect. Use the spreadsheet Bradford Manufacturing. In the spreadsheet, an area has been designated for your aggregate plan solution. Supply the number of packaging lines to run and the number of overtime hours for each quarter. You will need to set up the cost calculations in the spreadsheet.

You may want to try using the Excel Solver to find a low-cost solution. Remember that your final solution needs an integer number of lines and an integer number of overtime hours for each quarter. (Solutions that require 8.9134 lines and 1.256 hours of overtime are not feasible.)

It is important that your spreadsheet calculations are set up so that any values in the number of lines and overtime hours rows evaluates correctly. Your spreadsheet will be evaluated based on this.

2.Find a solution to the problem that goes beyond just minimizing cost. Prepare a short write-up that describes the process you went through to find your solution and that justifies why you think it is a good solution.

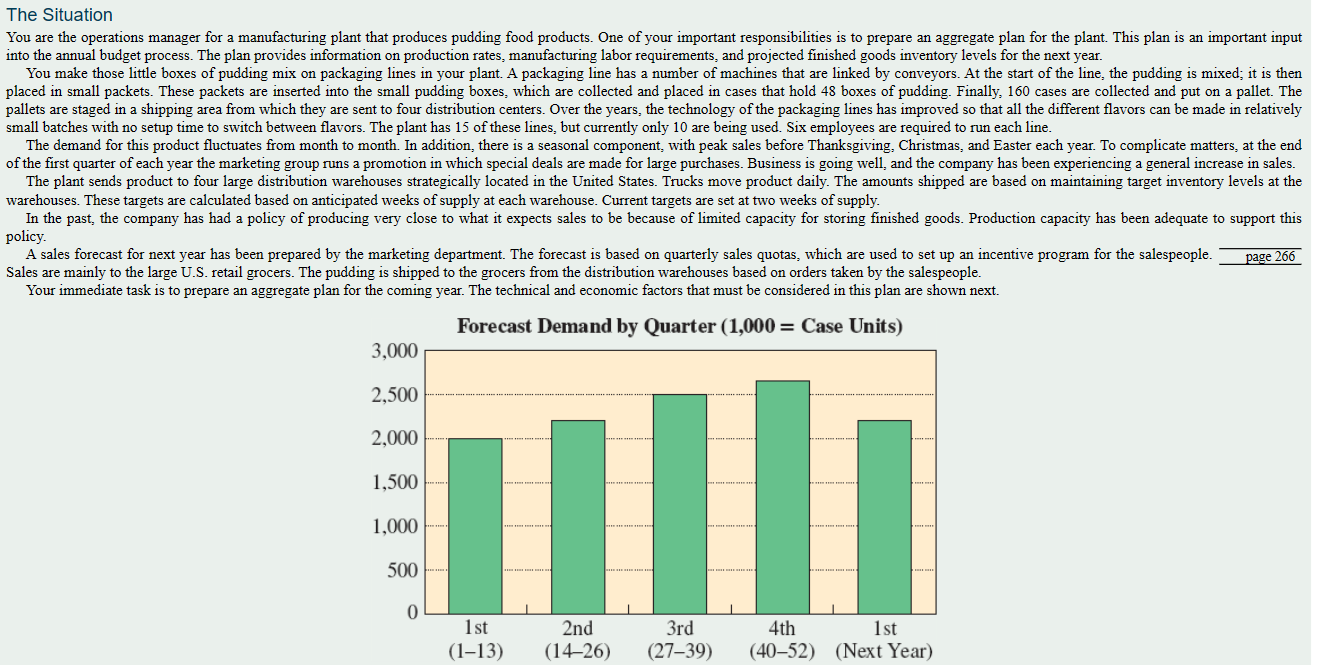

into the annual budget process. The plan provides information on production rates, manufacturing labor requirements, and projected finished goods inventory levels for the next year. small batches with no setup time to switch between flavors. The plant has 15 of these lines, but currently only 10 are being used. Six employees are required to run each line. warehouses. These targets are calculated based on anticipated weeks of supply at each warehouse. Current targets are set at two weeks of supply. policy. Sales are mainly to the large U.S. retail grocers. The pudding is shipped to the grocers from the distribution warehouses based on orders taken by the salespeople. Your immediate task is to prepare an aggregate plan for the coming year. The technical and economic factors that must be considered in this plan are shown next. cases/hour. stock requirement for each quarter: Q1-338; Q2-385; Q3-408; Q4-338. 6. The human resource group estimates that it costs $5,000 to hire and train a new production employee. It costs $3,000 to lay off a production worker. 7. Make the following assumptions in your cost calculations: - Inventory costs are based on inventory in excess of the safety stock requirement. - Backorder costs are incurred on the negative deviation from the planned safety stock requirement, even though planned inventory may be positive. - Overtime must be used over an entire quarter and should be based on hours per day over that time. Questions the number of overtime hours for each quarter. You will need to set up the cost calculations in the spreadsheet. It is important that your spreadsheet calculations are set up so that any values in the number of lines and overtime hours rows evaluates correctly. Your spreadsheet will be evaluated based on this. into the annual budget process. The plan provides information on production rates, manufacturing labor requirements, and projected finished goods inventory levels for the next year. small batches with no setup time to switch between flavors. The plant has 15 of these lines, but currently only 10 are being used. Six employees are required to run each line. warehouses. These targets are calculated based on anticipated weeks of supply at each warehouse. Current targets are set at two weeks of supply. policy. Sales are mainly to the large U.S. retail grocers. The pudding is shipped to the grocers from the distribution warehouses based on orders taken by the salespeople. Your immediate task is to prepare an aggregate plan for the coming year. The technical and economic factors that must be considered in this plan are shown next. cases/hour. stock requirement for each quarter: Q1-338; Q2-385; Q3-408; Q4-338. 6. The human resource group estimates that it costs $5,000 to hire and train a new production employee. It costs $3,000 to lay off a production worker. 7. Make the following assumptions in your cost calculations: - Inventory costs are based on inventory in excess of the safety stock requirement. - Backorder costs are incurred on the negative deviation from the planned safety stock requirement, even though planned inventory may be positive. - Overtime must be used over an entire quarter and should be based on hours per day over that time. Questions the number of overtime hours for each quarter. You will need to set up the cost calculations in the spreadsheet. It is important that your spreadsheet calculations are set up so that any values in the number of lines and overtime hours rows evaluates correctly. Your spreadsheet will be evaluated based on this

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts