Question: 1.The optimal production lot size would be: 2.The maximum inventory would be: 3.The number of production setups in a year would be: 4. The length

1.The optimal production lot size would be:

1.The optimal production lot size would be:

2.The maximum inventory would be:

3.The number of production setups in a year would be:

4. The length of each order cycle would be:

5.The length of time the rolling mill is operated in each cycle would be:

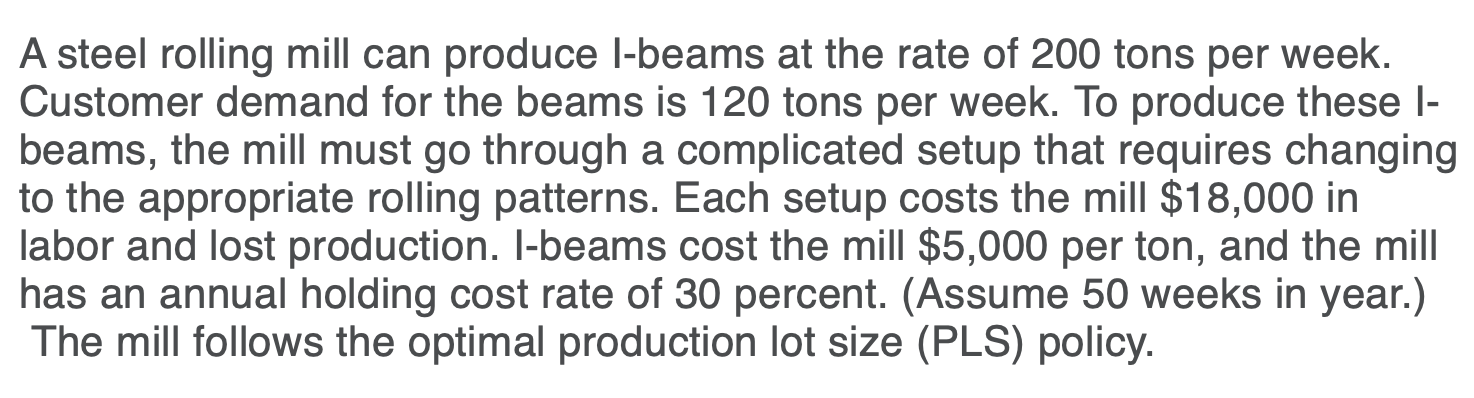

A steel rolling mill can produce l-beams at the rate of 200 tons per week. Customer demand for the beams is 120 tons per week. To produce these l- beams, the mill must go through a complicated setup that requires changing to the appropriate rolling patterns. Each setup costs the mill $18,000 in labor and lost production. I-beams cost the mill $5,000 per ton, and the mill has an annual holding cost rate of 30 percent. (Assume 50 weeks in year.) The mill follows the optimal production lot size (PLS) policy

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts