Question: ( 2 0 ) Prob. 5 : An iron blast furnace is assumed to be reducing pure F e 2 O 3 to Fe and

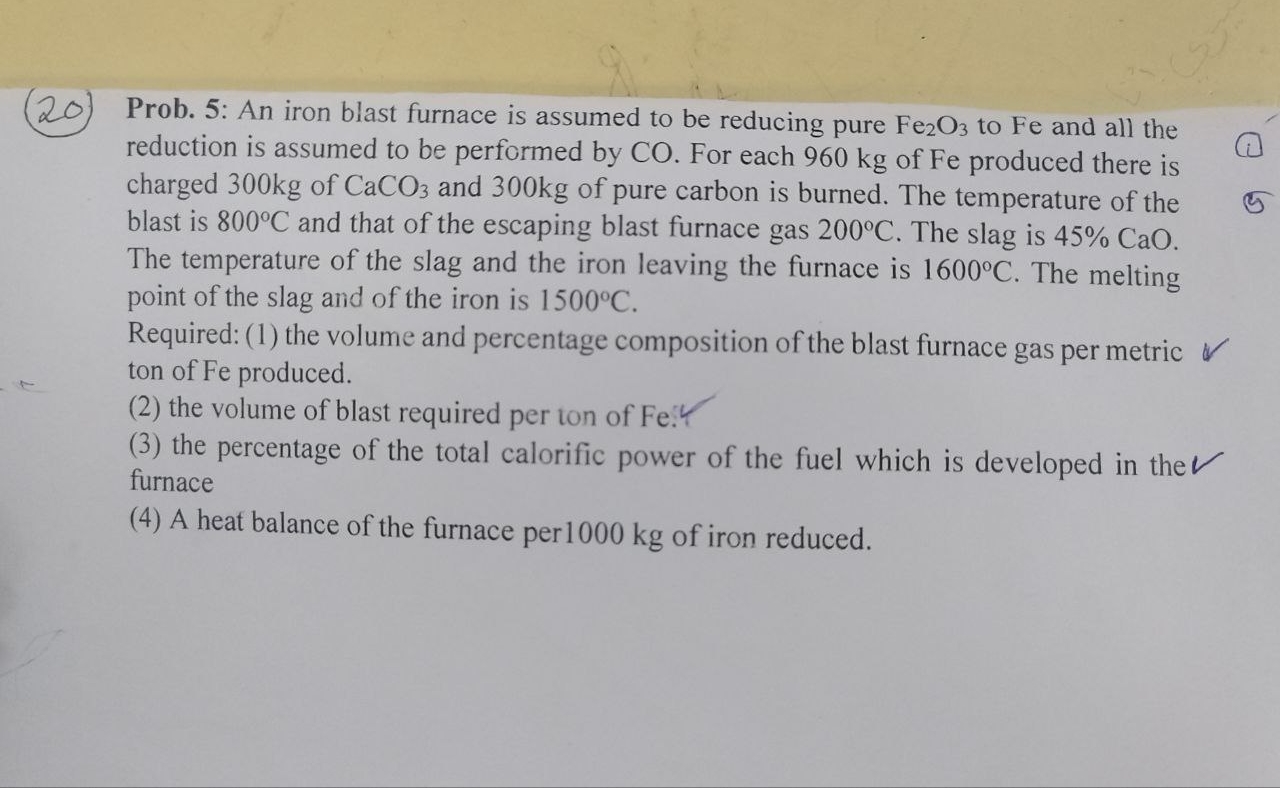

Prob. : An iron blast furnace is assumed to be reducing pure to Fe and all the reduction is assumed to be performed by CO For each kg of Fe produced there is charged kg of and kg of pure carbon is burned. The temperature of the blast is and that of the escaping blast furnace gas The slag is CaO. The temperature of the slag and the iron leaving the furnace is The melting point of the slag and of the iron is

Required: the volume and percentage composition of the blast furnace gas per metric ton of Fe produced.

the volume of blast required per ton of Fe :

the percentage of the total calorific power of the fuel which is developed in the furnace

A heat balance of the furnace per kg of iron reduced.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock