Question: 2. ( 25pts) Suppose the processing times for an automated (once the machine is running it doesn't require operator involvement) machining operation is 7 minutes

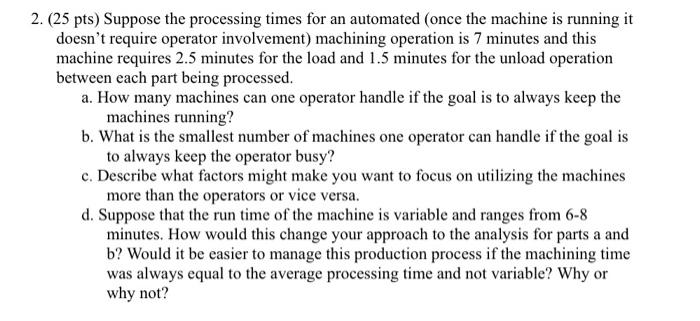

2. ( 25pts) Suppose the processing times for an automated (once the machine is running it doesn't require operator involvement) machining operation is 7 minutes and this machine requires 2.5 minutes for the load and 1.5 minutes for the unload operation between each part being processed. a. How many machines can one operator handle if the goal is to always keep the machines running? b. What is the smallest number of machines one operator can handle if the goal is to always keep the operator busy? c. Describe what factors might make you want to focus on utilizing the machines more than the operators or vice versa. d. Suppose that the run time of the machine is variable and ranges from 6-8 minutes. How would this change your approach to the analysis for parts a and b? Would it be easier to manage this production process if the machining time was always equal to the average processing time and not variable? Why or why not

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts