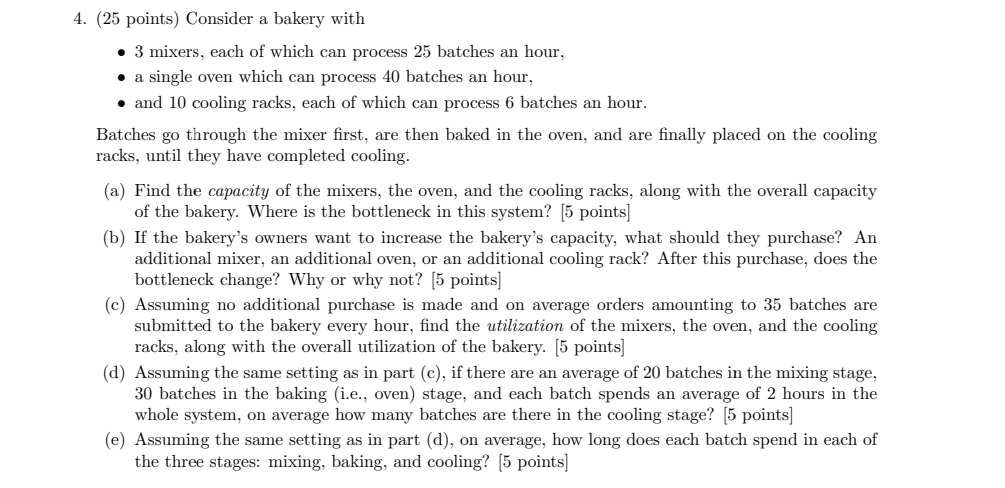

Question: ( 2 5 points ) Consider a bakery with 3 mixers, each of which can process 2 5 batches an hour, a single oven which

points Consider a bakery with

mixers, each of which can process batches an hour,

a single oven which can process batches an hour,

and cooling racks, each of which can process batches an hour.

Batches go through the mixer first, are then baked in the oven, and are finally placed on the cooling racks, until they have completed cooling.

a Find the capacity of the mixers, the oven, and the cooling racks, along with the overall capacity of the bakery. Where is the bottleneck in this system? points

b If the bakery's owners want to increase the bakery's capacity, what should they purchase? An additional mixer, an additional oven, or an additional cooling rack? After this purchase, does the bottleneck change? Why or why not? points

c Assuming no additional purchase is made and on average orders amounting to batches are submitted to the bakery every hour, find the utilization of the mixers, the oven, and the cooling racks, along with the overall utilization of the bakery. points

d Assuming the same setting as in part c if there are an average of batches in the mixing stage, batches in the baking ie oven stage, and each batch spends an average of hours in the whole system, on average how many batches are there in the cooling stage? points

e Assuming the same setting as in part d on average, how long does each batch spend in each of the three stages: mixing, baking, and cooling? points

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock