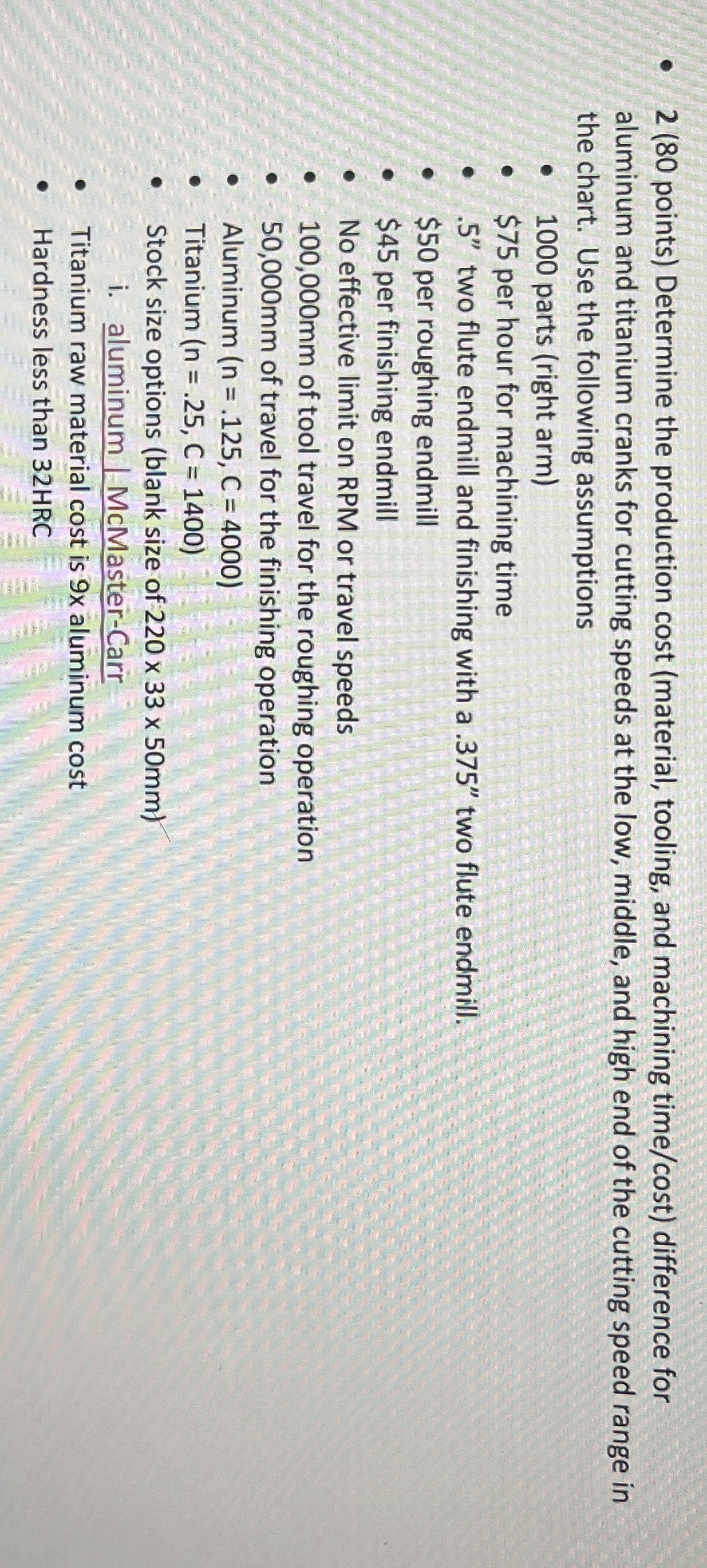

Question: 2 ( 8 0 points ) Determine the production cost ( material , tooling, and machining time / cost ) difference for aluminum and titanium

points Determine the production cost material tooling, and machining timecost difference for aluminum and titanium cranks for cutting speeds at the low, middle, and high end of the cutting speed range in the chart. Use the following assumptions

parts right arm

$ per hour for machining time

two flute endmill and finishing with a two flute endmill.

$ per roughing endmill

$ per finishing endmill

No effective limit on RPM or travel speeds

of tool travel for the roughing operation

of travel for the finishing operation

Aluminum

Titanium

Stock size options blank size of

i aluminum McMasterCarr

Titanium raw material cost is aluminum cost

Hardness less than HRC

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock