Question: 2. A completely mixed activated sludge system is to be used to treat the wastewater from a food manufacturing plant. They produce 0.75 mgd. All

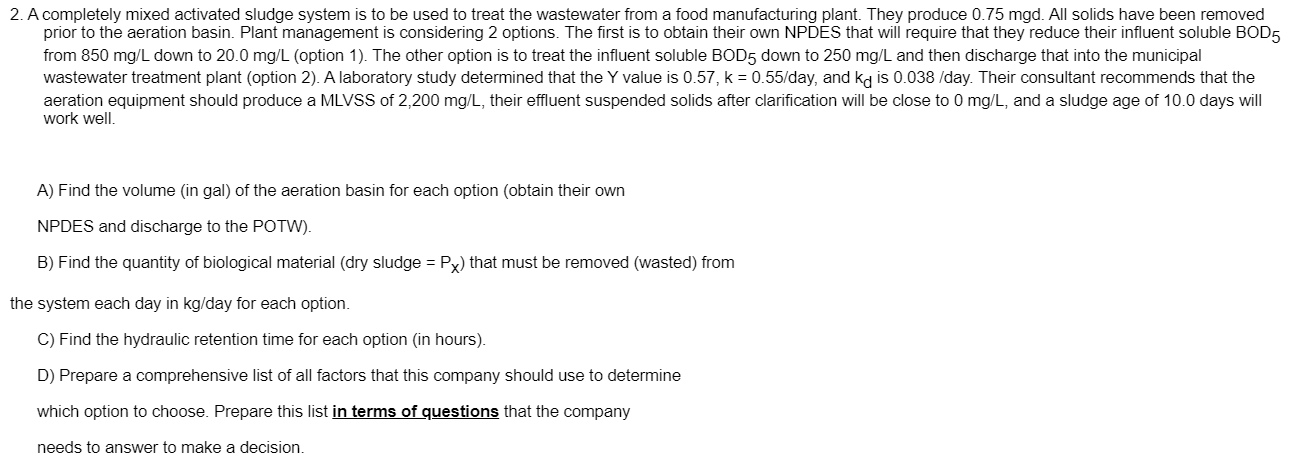

2. A completely mixed activated sludge system is to be used to treat the wastewater from a food manufacturing plant. They produce 0.75 mgd. All solids have been removed prior to the aeration basin. Plant management is considering 2 options. The first is to obtain their own NPDES that will require that they reduce their influent soluble BOD5 from 850 mg/L down to 20.0 mg/L (option 1). The other option is to treat the influent soluble BOD5 down to 250 mg/L and then discharge that into the municipal wastewater treatment plant (option 2). A laboratory study determined that the Y value is 0.57, k = 0.55/day, and ka is 0.038 /day. Their consultant recommends that the aeration equipment should produce a MLVSS of 2,200 mg/L, their effluent suspended solids after clarification will be close to 0 mg/L, and a sludge age of 10.0 days will work well. A) Find the volume (in gal) of the aeration basin for each option (obtain their own NPDES and discharge to the POTW). B) Find the quantity of biological material (dry sludge = Px) that must be removed (wasted) from the system each day in kg/day for each option. C) Find the hydraulic retention time for each option in hours). D) Prepare a comprehensive list of all factors that this company should use to determine which option to choose. Prepare this list in terms of questions that the company needs to answer to make a decision

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts