Question: 2. Chapter 6, problem 1. Statement of the problem A company has gathered the following financial information for itself and a competing firm. They wish

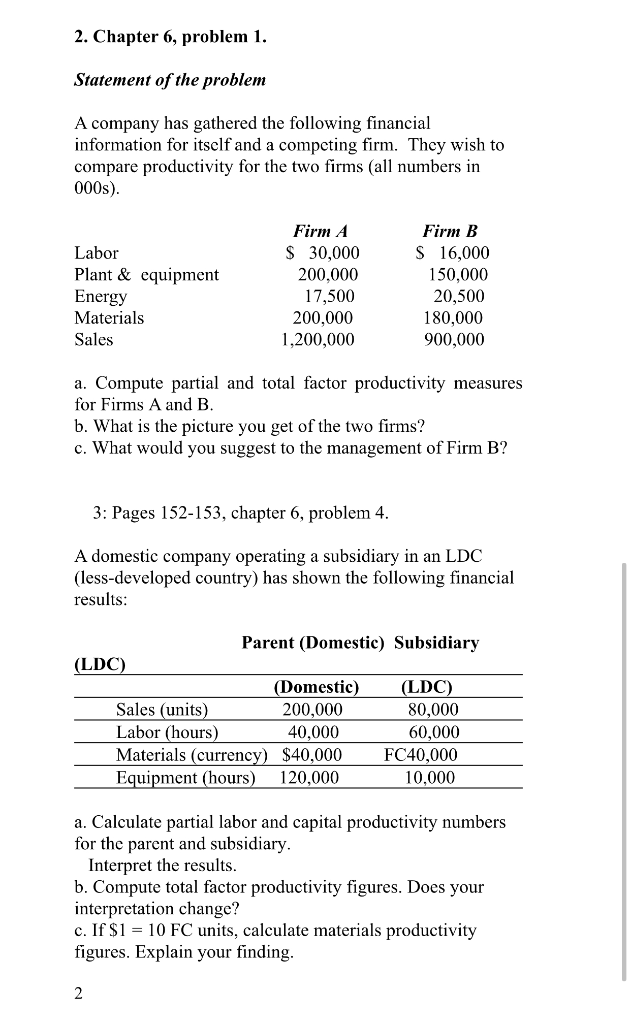

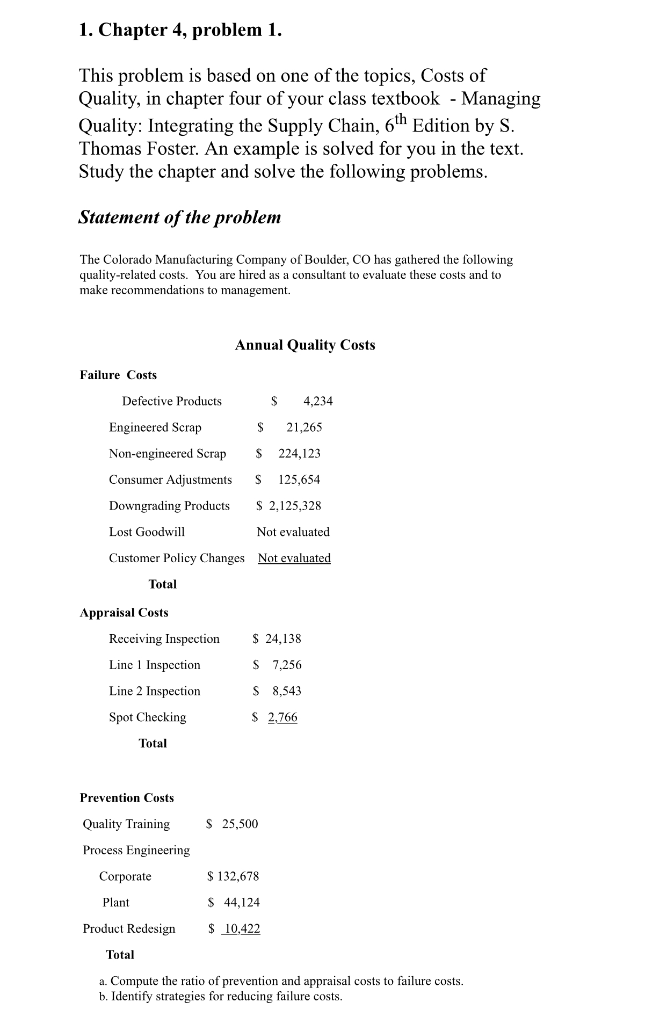

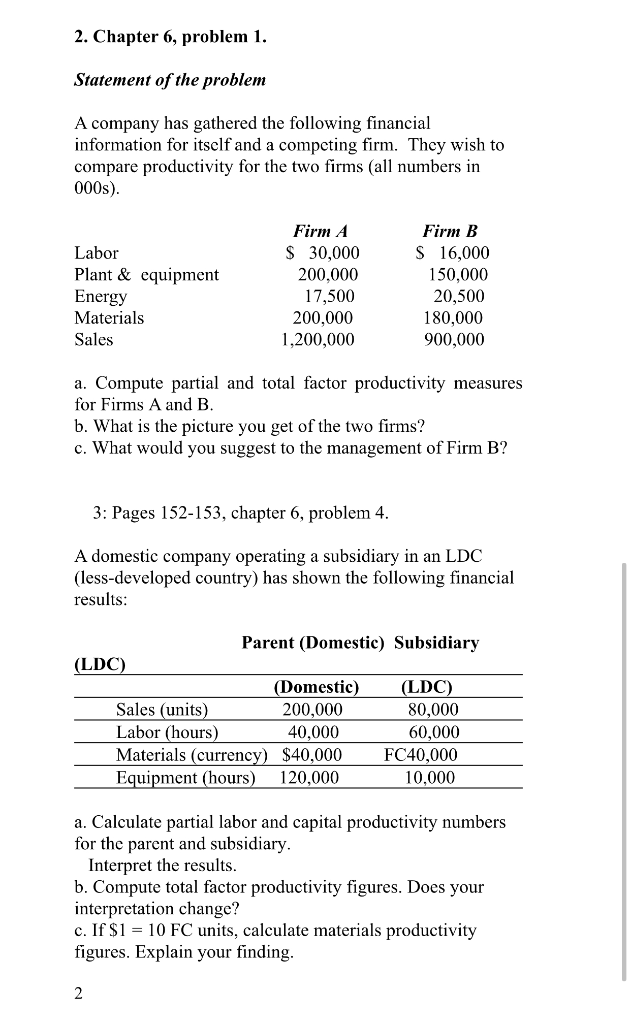

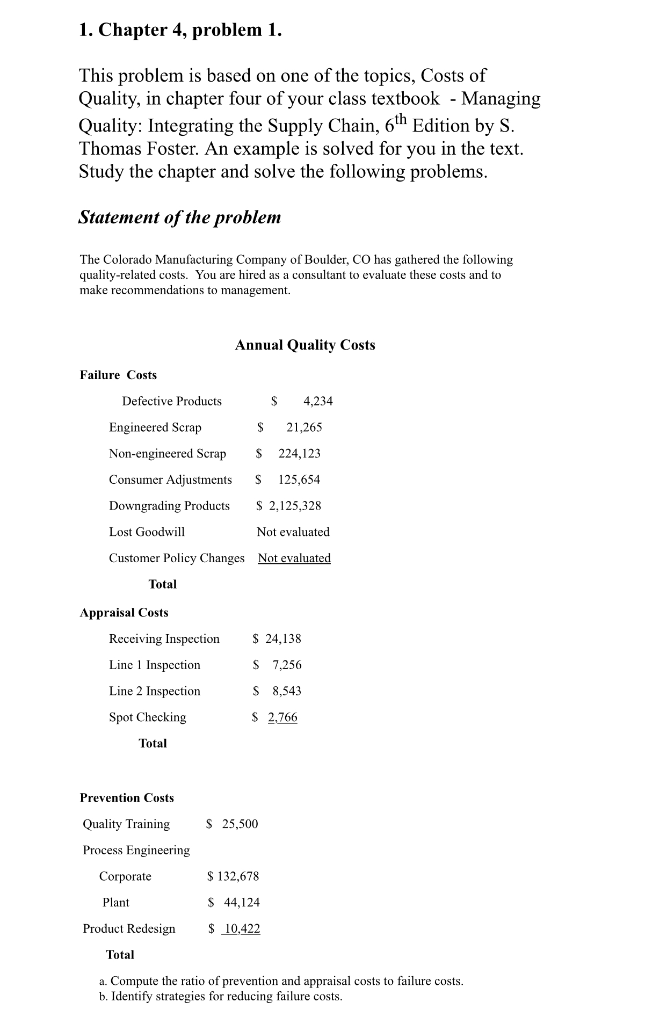

2. Chapter 6, problem 1. Statement of the problem A company has gathered the following financial information for itself and a competing firm. They wish to compare productivity for the two firms (all numbers in 000s). Labor Plant & equipment Energy Materials Sales Firm A $ 30,000 200.000 17,500 200,000 1,200,000 Firm B S 16,000 150,000 20,500 180,000 900,000 a. Compute partial and total factor productivity measures for Firms A and B. b. What is the picture you get of the two firms? c. What would you suggest to the management of Firm B? 3: Pages 152-153, chapter 6, problem 4. A domestic company operating a subsidiary in an LDC (less-developed country) has shown the following financial results: Parent (Domestic) Subsidiary (LDC) (Domestic) (LDC) Sales (units) 200,000 80,000 Labor (hours) 40,000 60,000 Materials (currency) $40,000 FC40,000 Equipment (hours) 120,000 10,000 a. Calculate partial labor and capital productivity numbers for the parent and subsidiary. Interpret the results. b. Compute total factor productivity figures. Does your interpretation change? c. If $1 = 10 FC units, calculate materials productivity figures. Explain your finding. 1. Chapter 4, problem 1. This problem is based on one of the topics, Costs of Quality, in chapter four of your class textbook - Managing Quality: Integrating the Supply Chain, 6th Edition by S. Thomas Foster. An example is solved for you in the text. Study the chapter and solve the following problems. Statement of the problem The Colorado Manufacturing Company of Boulder, CO has gathered the following quality-related costs. You are hired as a consultant to evaluate these costs and to make recommendations to management. Annual Quality Costs Failure Costs Defective Products Engineered Scrap Non-engineered Scrap Consumer Adjustments Downgrading Products $ 4,234 $ 21,265 $ 224,123 S 125,654 $2,125,328 Lost Goodwill Not evaluated Customer Policy Changes Not evaluated Total $ 24,138 Appraisal Costs Receiving Inspection Line 1 Inspection Line 2 Inspection Spot Checking $ 7,256 $ 8,543 $ 2,766 Total $ 25,500 Prevention Costs Quality Training Process Engineering Corporate Plant Product Redesign $ 132,678 S 44,124 $ 10,422 Total a. Compute the ratio of prevention and appraisal costs to failure costs. b. Identify strategies for reducing failure costs