Question: 2. Consider the following manufacturing system where two distinct types of parts are processed on two distinct machines located at the first station and then

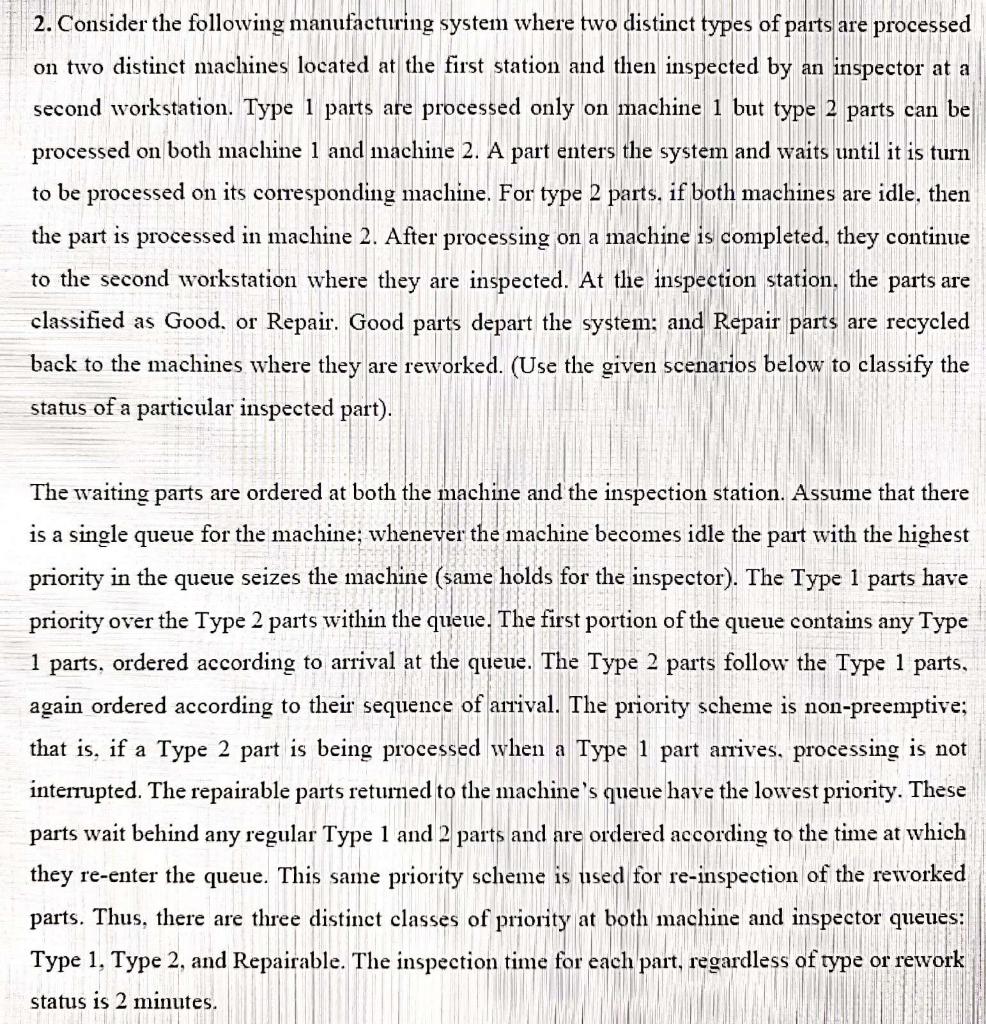

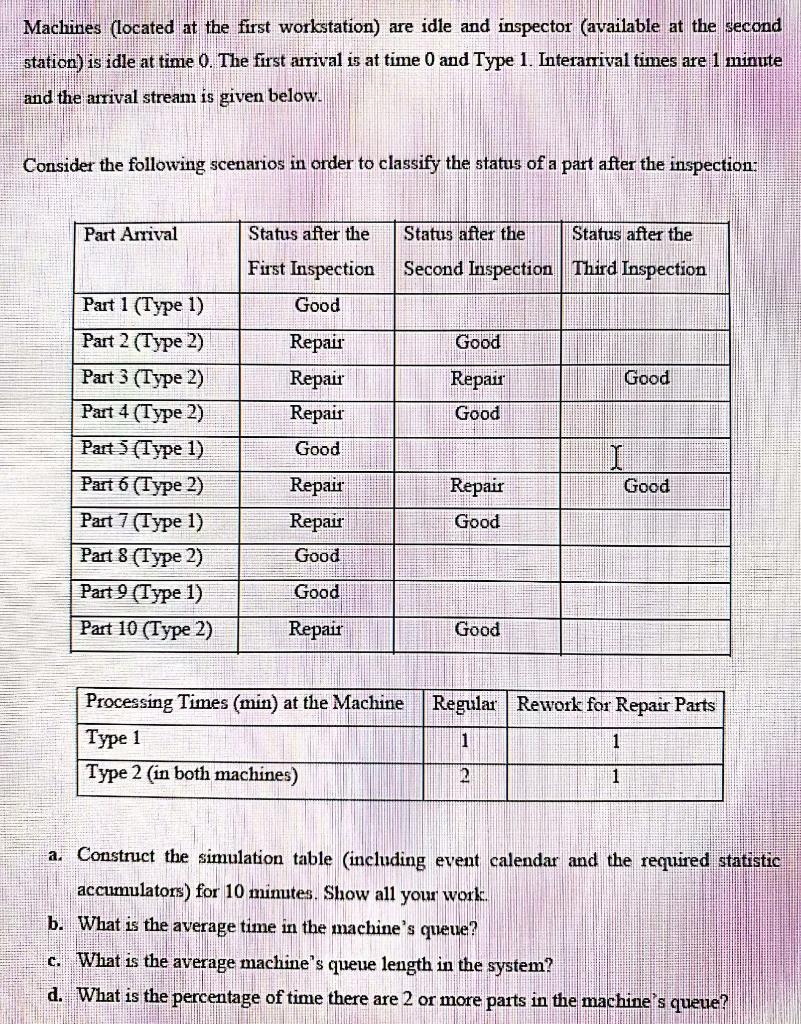

2. Consider the following manufacturing system where two distinct types of parts are processed on two distinct machines located at the first station and then inspected by an inspector at a second workstation. Type 1 parts are processed only on machine 1 but type 2 parts can be processed on both machine 1 and machine 2. A part enters the system and waits until it is turn to be processed on its corresponding machine. For type 2 parts. if both machines are idle, then the part is processed in machine 2. After processing on a machine is completed, they continue to the second workstation where they are inspected. At the inspection station, the parts are classified as Good, or Repair. Good parts depart the system; and Repair parts are recycled back to the machines where they are reworked. (Use the given scenarios below to classify the status of a particular inspected part). The waiting parts are ordered at both the machine and the inspection station. Assume that there is a single queue for the machine; whenever the machine becomes idle the part with the highest priority in the queue seizes the machine (same holds for the inspector). The Type 1 parts have priority over the Type 2 parts within the queue. The first portion of the queue contains any Type 1 parts, ordered according to arrival at the queue. The Type 2 parts follow the Type 1 parts, again ordered according to their sequence of arrival. The priority scheme is non-preemptive; that is, if a Type 2 part is being processed when a Type 1 part arrives, processing is not interrupted. The repairable parts returned to the machine's queue have the lowest priority. These parts wait behind any regular Type 1 and 2 parts and are ordered according to the time at which they re-enter the queue. This same priority scheme is used for re-inspection of the reworked parts. Thus, there are three distinct classes of priority at both machine and inspector queues: Type 1, Type 2, and Repairable. The inspection time for each part, regardless of type or rework status is 2 minutes, Machines (located at the first workstation) are idle and inspector (available at the second station) is idle at time 0. The first airival is at time 0 and Type 1. Interanrival times are 1 minute and the arrival stream is given below. Consider the following scenarios in order to classify the status of a part after the inspection: Part Arrival Status after the Status after the Status after the First Inspection Second Inspection Third Inspection Good Good Repair Repair Repair Repair Good Good Good Part 1 (Type 1) Part 2 (Type 2) Part 3 (Type 2) Part 4 (Type 2) Part 5 (Type 1) Part 6 (Type 2) Part 7 (Type 1) Part 8 (Type 2) Part 9 (Type 1) Part 10 (Type 2) Repair Good Repair Repair Good Good Good Repair Good Processing Times (min) at the Machine Type 1 Type 2 (in both machines) Regular Rework for Repair Parts 1 1 2 1 a. Construct the simulation table (including event calendar and the required statistic accumulators) for 10 minutes. Show all your work. b. What is the average time in the machine's queue? c. What is the average machine's queue length in the system? d. What is the percentage of time there are 2 or more parts in the machine's queue? 2. Consider the following manufacturing system where two distinct types of parts are processed on two distinct machines located at the first station and then inspected by an inspector at a second workstation. Type 1 parts are processed only on machine 1 but type 2 parts can be processed on both machine 1 and machine 2. A part enters the system and waits until it is turn to be processed on its corresponding machine. For type 2 parts. if both machines are idle, then the part is processed in machine 2. After processing on a machine is completed, they continue to the second workstation where they are inspected. At the inspection station, the parts are classified as Good, or Repair. Good parts depart the system; and Repair parts are recycled back to the machines where they are reworked. (Use the given scenarios below to classify the status of a particular inspected part). The waiting parts are ordered at both the machine and the inspection station. Assume that there is a single queue for the machine; whenever the machine becomes idle the part with the highest priority in the queue seizes the machine (same holds for the inspector). The Type 1 parts have priority over the Type 2 parts within the queue. The first portion of the queue contains any Type 1 parts, ordered according to arrival at the queue. The Type 2 parts follow the Type 1 parts, again ordered according to their sequence of arrival. The priority scheme is non-preemptive; that is, if a Type 2 part is being processed when a Type 1 part arrives, processing is not interrupted. The repairable parts returned to the machine's queue have the lowest priority. These parts wait behind any regular Type 1 and 2 parts and are ordered according to the time at which they re-enter the queue. This same priority scheme is used for re-inspection of the reworked parts. Thus, there are three distinct classes of priority at both machine and inspector queues: Type 1, Type 2, and Repairable. The inspection time for each part, regardless of type or rework status is 2 minutes, Machines (located at the first workstation) are idle and inspector (available at the second station) is idle at time 0. The first airival is at time 0 and Type 1. Interanrival times are 1 minute and the arrival stream is given below. Consider the following scenarios in order to classify the status of a part after the inspection: Part Arrival Status after the Status after the Status after the First Inspection Second Inspection Third Inspection Good Good Repair Repair Repair Repair Good Good Good Part 1 (Type 1) Part 2 (Type 2) Part 3 (Type 2) Part 4 (Type 2) Part 5 (Type 1) Part 6 (Type 2) Part 7 (Type 1) Part 8 (Type 2) Part 9 (Type 1) Part 10 (Type 2) Repair Good Repair Repair Good Good Good Repair Good Processing Times (min) at the Machine Type 1 Type 2 (in both machines) Regular Rework for Repair Parts 1 1 2 1 a. Construct the simulation table (including event calendar and the required statistic accumulators) for 10 minutes. Show all your work. b. What is the average time in the machine's queue? c. What is the average machine's queue length in the system? d. What is the percentage of time there are 2 or more parts in the machine's queue