Question: 2. Fill in the following table to prepare a master production schedule for end item 'F' using the lot-for-lot rule. The beginning inventory for

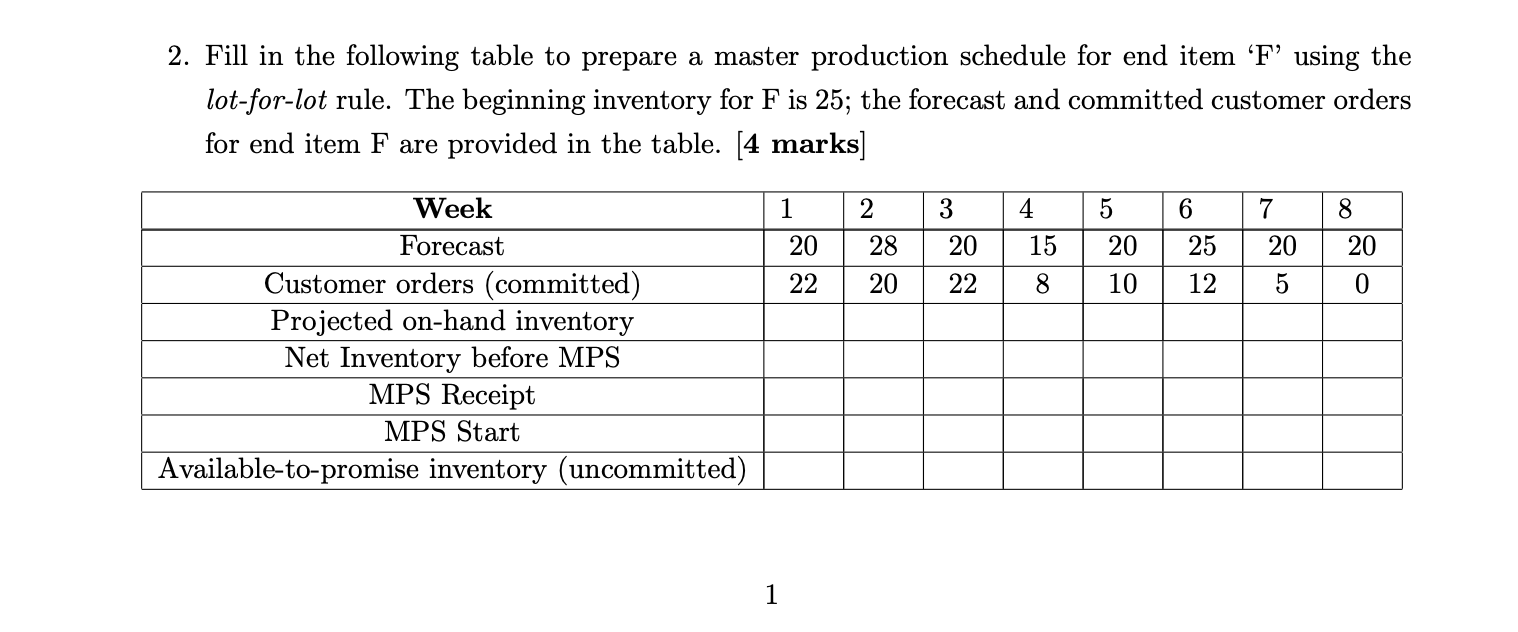

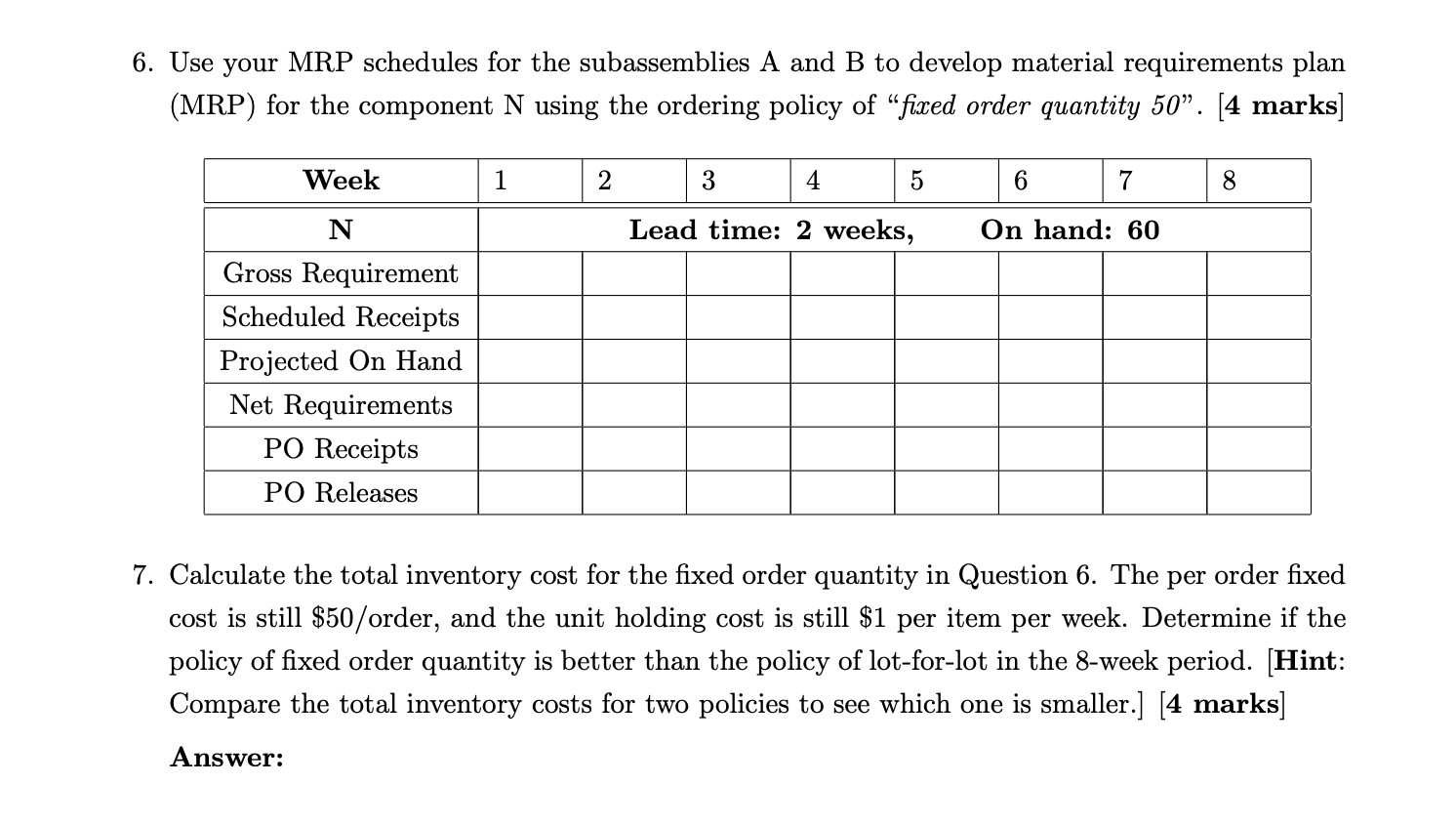

2. Fill in the following table to prepare a master production schedule for end item 'F' using the lot-for-lot rule. The beginning inventory for F is 25; the forecast and committed customer orders for end item F are provided in the table. [4 marks] Week Forecast Customer orders (committed) Projected on-hand inventory Net Inventory before MPS MPS Receipt MPS Start Available-to-promise inventory (uncommitted) 1 1 20 22 2 3 28 20 20 22 4 15 8 5 20 10 6 25 12 7 20 5 8 20 0 6. Use your MRP schedules for the subassemblies A and B to develop material requirements plan (MRP) for the component N using the ordering policy of "fixed order quantity 50". [4 marks] Week N Gross Requirement Scheduled Receipts Projected On Hand Net Requirements PO Receipts PO Releases 1 2 4 Lead time: 2 weeks, 3 5 7 6 On hand: 60 8 7. Calculate the total inventory cost for the fixed order quantity in Question 6. The per order fixed cost is still $50/order, and the unit holding cost is still $1 per item per week. Determine if the policy of fixed order quantity is better than the policy of lot-for-lot in the 8-week period. [Hint: Compare the total inventory costs for two policies to see which one is smaller.] [4 marks] Answer:

Step by Step Solution

3.48 Rating (165 Votes )

There are 3 Steps involved in it

To prepare a master production schedule MPS for end item F using the lotforlot rule we need to calcu... View full answer

Get step-by-step solutions from verified subject matter experts