Question: 2. Given the following data: - Actual production last week =32,000 units - Effective capacity =35,000 units - Design capacity =250 units per hour -

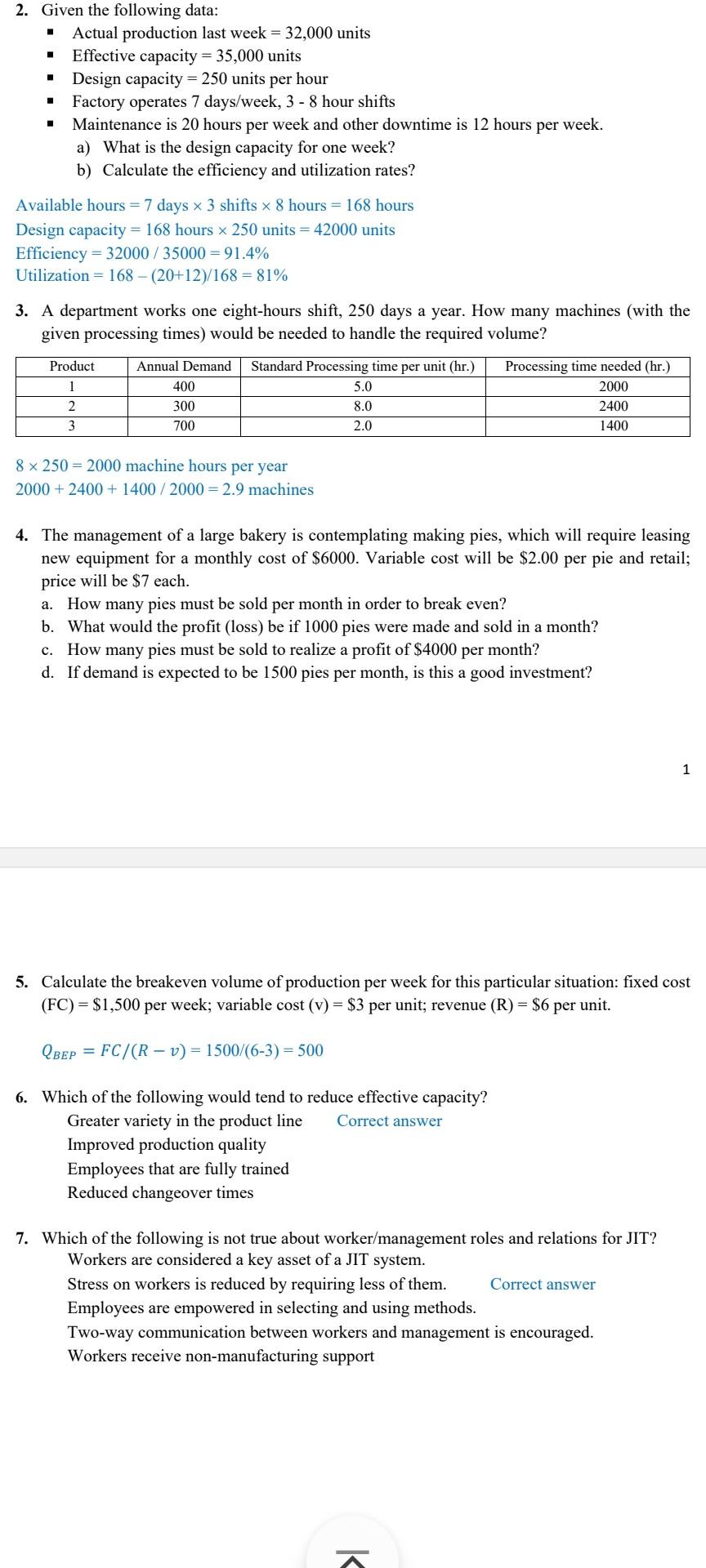

2. Given the following data: - Actual production last week =32,000 units - Effective capacity =35,000 units - Design capacity =250 units per hour - Factory operates 7 days/week, 3 - 8 hour shifts - Maintenance is 20 hours per week and other downtime is 12 hours per week. a) What is the design capacity for one week? b) Calculate the efficiency and utilization rates? Available hours =7 days 3 shifts 8 hours =168 hours Design capacity =168 hours 250 units =42000 units Efficiency =32000/35000=91.4% Utilization =168(20+12)/168=81% 3. A department works one eight-hours shift, 250 days a year. How many machines (with the given processing times) would be needed to handle the required volume? 8250=2000 machine hours per year 2000+2400+1400/2000=2.9 machines 4. The management of a large bakery is contemplating making pies, which will require leasing new equipment for a monthly cost of $6000. Variable cost will be $2.00 per pie and retail; price will be $7 each. a. How many pies must be sold per month in order to break even? b. What would the profit (loss) be if 1000 pies were made and sold in a month? c. How many pies must be sold to realize a profit of $4000 per month? d. If demand is expected to be 1500 pies per month, is this a good investment? 1 5. Calculate the breakeven volume of production per week for this particular situation: fixed cost (FC)=$1,500 per week; variable cost (v)=$3 per unit; revenue (R)=$6 per unit. QBEP=FC/(Rv)=1500/(63)=500 6. Which of the following would tend to reduce effective capacity? Greater variety in the product line Correct answer Improved production quality Employees that are fully trained Reduced changeover times 7. Which of the following is not true about worker/management roles and relations for JIT? Workers are considered a key asset of a JIT system. Stress on workers is reduced by requiring less of them. Correct answer Employees are empowered in selecting and using methods. Two-way communication between workers and management is encouraged. Workers receive non-manufacturing support

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts