Question: #2: In a manufacturing process, an organic solvent (methyl ethyl ketone, MEK) is used to dissolve a thin coating of a polymer film away from

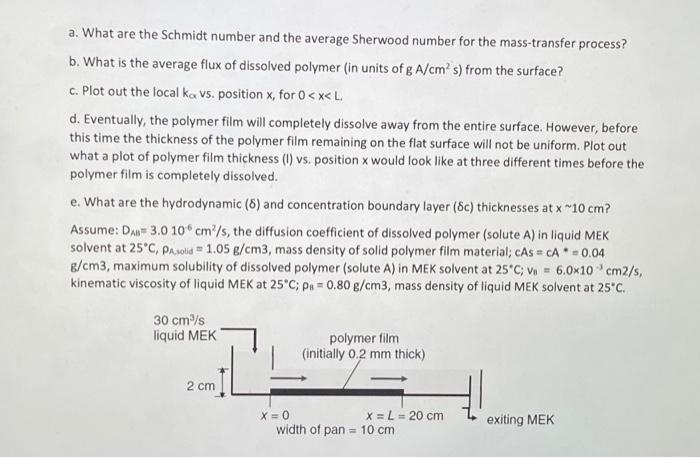

\#2: In a manufacturing process, an organic solvent (methyl ethyl ketone, MEK) is used to dissolve a thin coating of a polymer film away from a nonporous flat surface of length 30cm and width 10cm, as shown in the figure (below). The thickness of the polymer film is initially uniform at I=0.20mm. In the present process, a volumetric flow rate of 20cm3/s of MEK liquid solvent is added to an open flat pan of length 30cm and width 10cm. The depth of the liquid MEK solvent in the pan is maintained at 2.0cm. It may be assumed that the concentration of dissolved polymer in the bulk solvent is essentially zero, even though in reality the concentration of dissolved polymer in the solvent increases very slightly from the entrance to the exit of the pan. It may also be assumed that the change film thickness during the dissolution process does not affect the convection mass transfer process. Let A be the polymer (solute), B the MEK (liquid solvent). a. What are the Schmidt number and the average Sherwood number for the mass-transfer process? b. What is the average flux of dissolved polymer (in units of gA/cm2s ) from the surface? c. Plot out the local ka vs. position x, for 0

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts