Question: #2 please 13. Process Quality in Wound Closure (16 points) A start-up called Surgi-Stik, Inc. (SSI) has developed a wound closure adhesive intended for surgeons

#2 please

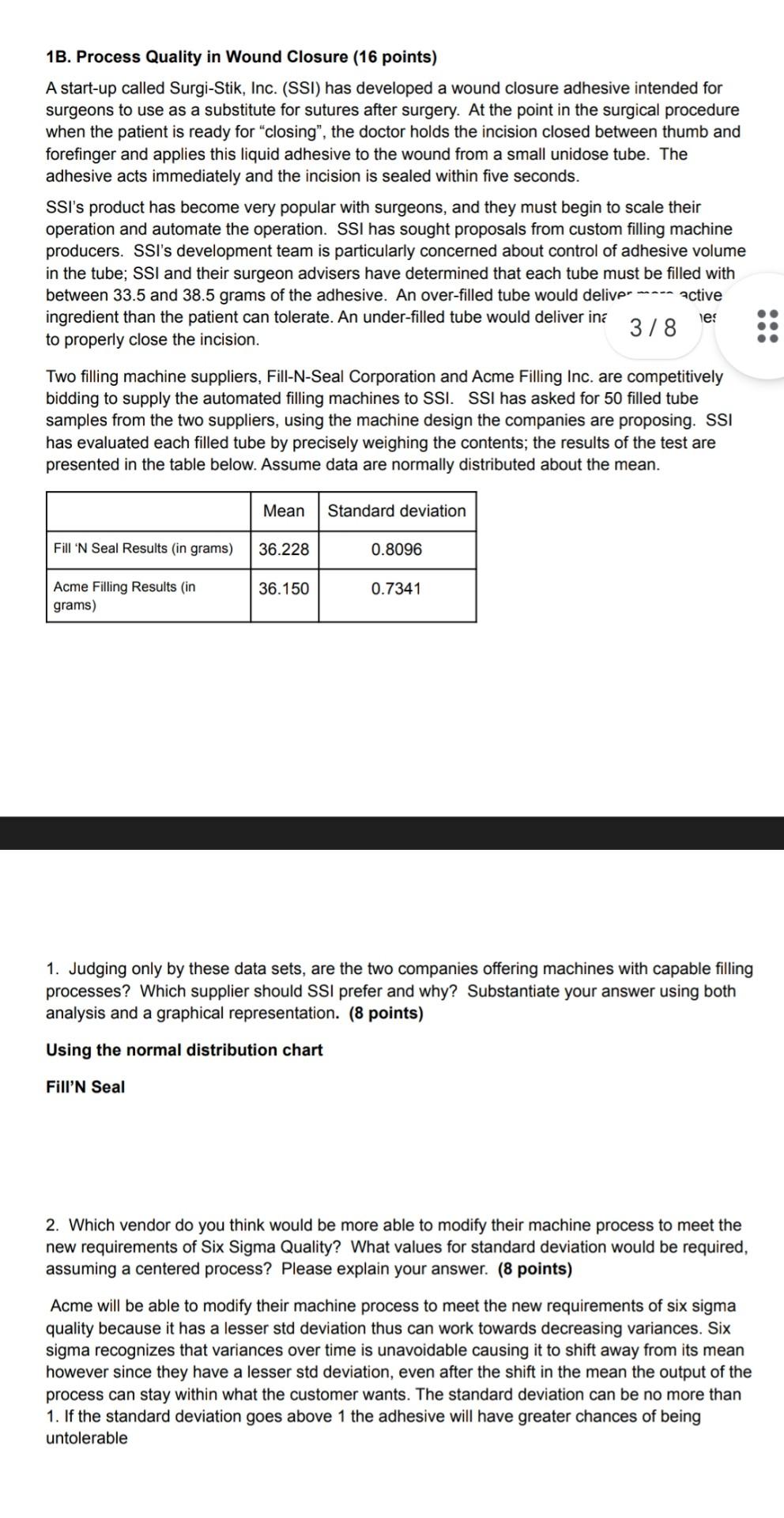

13. Process Quality in Wound Closure (16 points) A start-up called Surgi-Stik, Inc. (SSI) has developed a wound closure adhesive intended for surgeons to use as a substitute for sutures after surgery. At the point in the surgical procedure when the patient is ready for closing", the doctor holds the incision closed between thumb and forefinger and applies this liquid adhesive to the wound from a small unidose tube. The adhesive acts immediately and the incision is sealed within five seconds. SSI's product has become very popular with surgeons, and they must begin to scale their operation and automate the operation. SSI has sought proposals from custom filling machine producers. SSI's development team is particularly concerned about control of adhesive volume in the tube; SSI and their surgeon advisers have determined that each tube must be filled with between 33.5 and 38.5 grams of the adhesive. An over-filled tube would deliver ---- active ingredient than the patient can tolerate. An under-filled tube would deliver in les 3/8 to properly close the incision. .. Two filling machine suppliers, Fill-N-Seal Corporation and Acme Filling Inc. are competitively bidding to supply the automated filling machines to SSI. SSI has asked for 50 filled tube samples from the two suppliers, using the machine design the companies are proposing. SSI has evaluated each filled tube by precisely weighing the contents; the results of the test are presented in the table below. Assume data are normally distributed about the mean. Mean Standard deviation Fill 'N Seal Results (in grams) 36.228 0.8096 Acme Filling Results (in grams) 36.150 0.7341 1. Judging only by these data sets, are the two companies offering machines with capable filling processes? Which supplier should SSI prefer and why? Substantiate your answer using both analysis and a graphical representation. (8 points) Using the normal distribution chart FilI'N Seal 2. Which vendor do you think would be more able to modify their machine process to meet the new requirements of Six Sigma Quality? What values for standard deviation would be required, assuming a centered process? Please explain your answer. (8 points) Acme will be able to modify their machine process to meet the new requirements of six sigma quality because it has a lesser std deviation thus can work towards decreasing variances. Six sigma recognizes that variances over time is unavoidable causing it to shift away from its mean however since they have a lesser std deviation, even after the shift in the mean the output of the process can stay within what the customer wants. The standard deviation can be no more than 1. If the standard deviation goes above 1 the adhesive will have greater chances of being untolerableStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock