Question: 2. (SHOW YOUR COMPLETE WORK) A company has been using MRP to manufacture power tools for a number of years. Recently, Bianca Hill, the operations

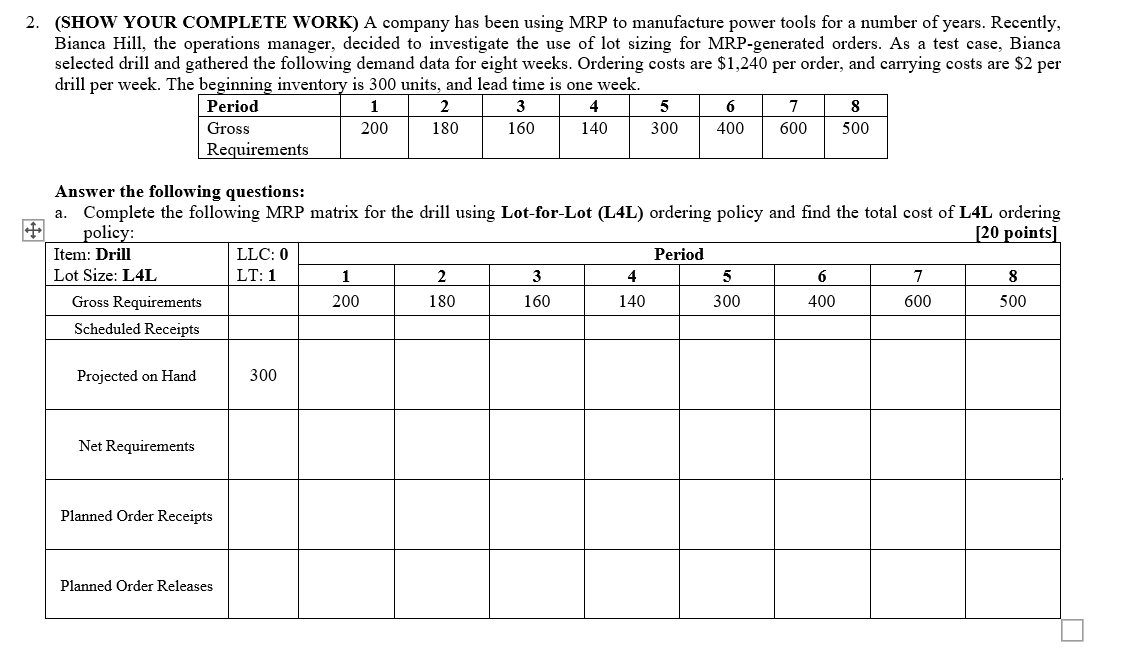

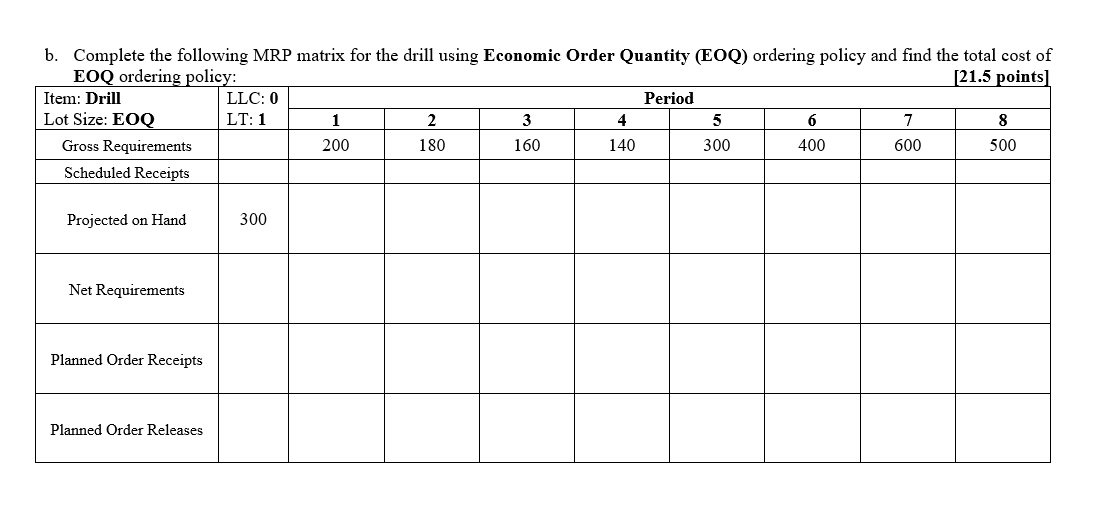

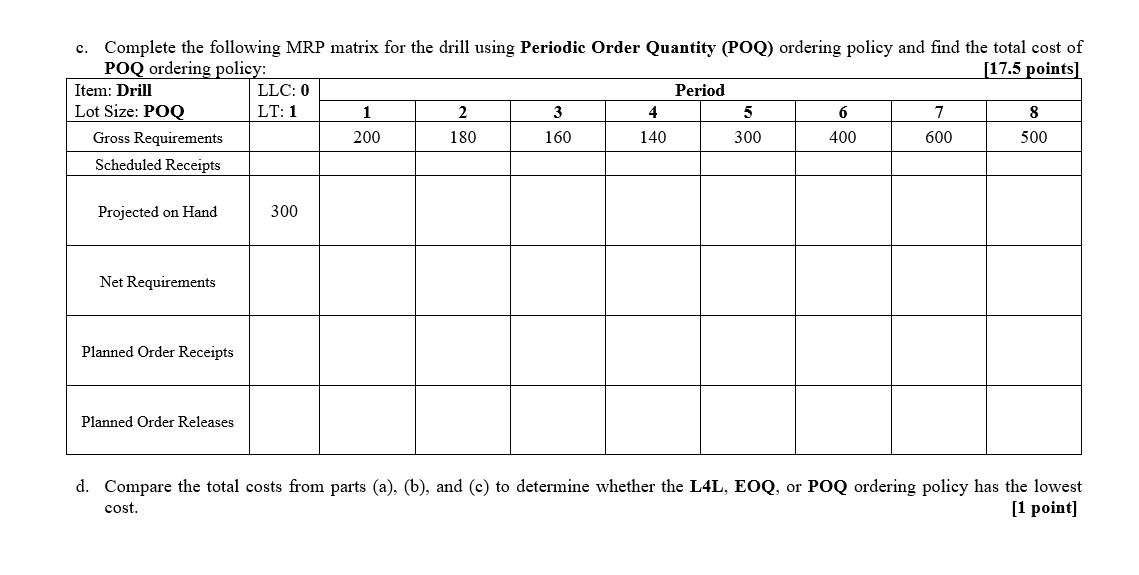

2. (SHOW YOUR COMPLETE WORK) A company has been using MRP to manufacture power tools for a number of years. Recently, Bianca Hill, the operations manager, decided to investigate the use of lot sizing for MRP-generated orders. As a test case, Bianca selected drill and gathered the following demand data for eight weeks. Ordering costs are $1,240 per order, and carrying costs are $2 per drill per week. The beginning inventory is 300 units, and lead time is one week. Period 1 2 3 5 7 8 Gross 200 180 160 140 300 400 600 500 Requirements 4 6 Answer the following questions: a. Complete the following MRP matrix for the drill using Lot-for-Lot (L4L) ordering policy and find the total cost of L4L ordering policy: [20 points) Item: Drill LLC: 0 Period Lot Size: L4L LT: 1 1 2 3 4 5 6 7 8 Gross Requirements 200 180 160 140 300 400 600 500 Scheduled Receipts Projected on Hand 300 Net Requirements Planned Order Receipts Planned Order Releases b. Complete the following MRP matrix for the drill using Economic Order Quantity (EOQ) ordering policy and find the total cost of EOQ ordering policy: (21.5 points) Item: Drill LLC: 0 Period Lot Size: EOQ LT: 1 1 2 3 4 5 6 7 8 Gross Requirements 200 180 160 140 300 400 600 500 Scheduled Receipts Projected on Hand 300 Net Requirements Planned Order Receipts Planned Order Releases c. Complete the following MRP matrix for the drill using Periodic Order Quantity (POQ) ordering policy and find the total cost of POQ ordering policy: (17.5 points) Item: Drill LLC: 0 Period Lot Size: POQ LT: 1 1 2 3 4 5 6 7 8 Gross Requirements 200 180 160 140 300 400 600 500 Scheduled Receipts Projected on Hand 300 Net Requirements Planned Order Receipts Planned Order Releases d. Compare the total costs from parts (a), (b), and (c) to determine whether the L4L, EOQ, or POQ ordering policy has the lowest [1 point] cost. 2. (SHOW YOUR COMPLETE WORK) A company has been using MRP to manufacture power tools for a number of years. Recently, Bianca Hill, the operations manager, decided to investigate the use of lot sizing for MRP-generated orders. As a test case, Bianca selected drill and gathered the following demand data for eight weeks. Ordering costs are $1,240 per order, and carrying costs are $2 per drill per week. The beginning inventory is 300 units, and lead time is one week. Period 1 2 3 5 7 8 Gross 200 180 160 140 300 400 600 500 Requirements 4 6 Answer the following questions: a. Complete the following MRP matrix for the drill using Lot-for-Lot (L4L) ordering policy and find the total cost of L4L ordering policy: [20 points) Item: Drill LLC: 0 Period Lot Size: L4L LT: 1 1 2 3 4 5 6 7 8 Gross Requirements 200 180 160 140 300 400 600 500 Scheduled Receipts Projected on Hand 300 Net Requirements Planned Order Receipts Planned Order Releases b. Complete the following MRP matrix for the drill using Economic Order Quantity (EOQ) ordering policy and find the total cost of EOQ ordering policy: (21.5 points) Item: Drill LLC: 0 Period Lot Size: EOQ LT: 1 1 2 3 4 5 6 7 8 Gross Requirements 200 180 160 140 300 400 600 500 Scheduled Receipts Projected on Hand 300 Net Requirements Planned Order Receipts Planned Order Releases c. Complete the following MRP matrix for the drill using Periodic Order Quantity (POQ) ordering policy and find the total cost of POQ ordering policy: (17.5 points) Item: Drill LLC: 0 Period Lot Size: POQ LT: 1 1 2 3 4 5 6 7 8 Gross Requirements 200 180 160 140 300 400 600 500 Scheduled Receipts Projected on Hand 300 Net Requirements Planned Order Receipts Planned Order Releases d. Compare the total costs from parts (a), (b), and (c) to determine whether the L4L, EOQ, or POQ ordering policy has the lowest [1 point] cost

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts