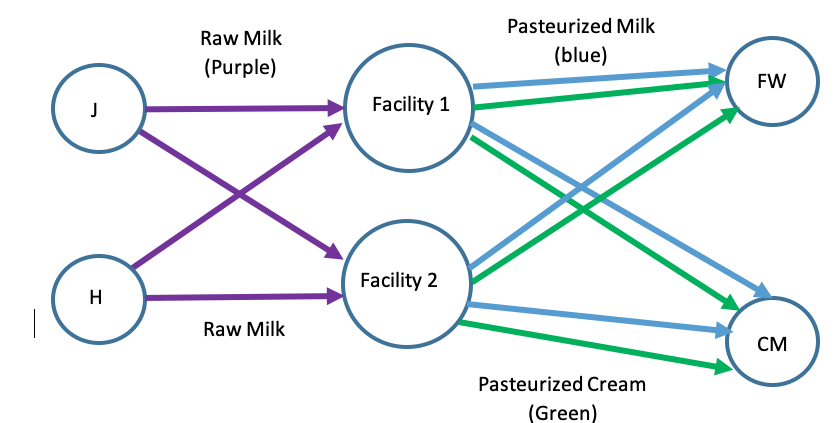

Question: #2. The Daisy Dairy Co. has two processing facilities that buy raw unpasteurized milk from two farms, Jersey Farms and Holstein Farms, and process it

#2. The Daisy Dairy Co. has two processing facilities that buy raw unpasteurized milk from two farms, Jersey Farms and Holstein Farms, and process it into pasteurized milk and cream for two local grocery chains, Food Wholes and Central Markup. The two farms pay for shipping to the dairys two processing facilities. Jersey can produce up to 14000 gallons of raw unpasteurized milk each day and Holstein can produce up to 12000 gallons. The purchasing costs, processing costs, and yields are summarized in the table below.

| Farm-Facility | Raw Milk Price (/gal) | Processing Costs (/gal) | Milk Yield | Cream Yield |

| Jersey - Facility 1 | $1.88 | $0.90 | 0.78 gal | 0.18 gal |

| Holstein - Facility 1 | $1.73 | $0.90 | 0.85 gal | 0.12 gal |

| Jersey - Facility 2 | $1.69 | $1.00 | 0.80 gal | 0.16 gal |

| Holstein - Facility 2 | $1.79 | $1.00 | 0.83 gal | 0.10 gal |

(Interpretation: A gallon of raw milk purchased from the Jersey Farm by Facility 1 costs Daisy $1.88, plus $.90/gal to process at Facility 1, and yields .78 gallons of pasteurized milk and .18 gallons of cream.)

Food Wholes requires 8000 gallons of pasteurized milk and 1500 gallons of pasteurized cream per day; Central Markup requires 11000 gallons of pasteurized milk and 1850 gallons of pasteurized cream per day. Daisy Dairy Co. incurs all shipping costs for moving pasteurized milk and cream from their two facilities to the two grocery chains. These costs are summarized in the table below.

| Chain | Shipping Costs Milk (/gal) | Shipping Costs Cream (/gal)) |

| Facility 1 - Food Wholes | $0.35 | $0.45 |

| Facility 1 - Central Markup | $0.45 | $0.55 |

| Facility 2 - Food Wholes | $0.40 | $0.50 |

| Facility 2 - Central Markup | $0.37 | $0.47 |

Formulate an LP that helps Daisy Dairy determine how much raw milk to buy and process from each farm for each facility per day. Use decision variables J1 = gallons of raw milk to buy from Jersey Farm to process at Facility 1, H1 = gallons of raw milk from Holstein Farm at Facility 1, etc. Use M1F = gallons of milk to ship from Facility 1 to Food Wholes, C1F = gallons of cream to ship from Facility 1 to Food Wholes, etc. You may assume that Daisy Dairy can dispose of any surplus pasteurized milk or cream that is produced at their facilities but not needed for shipment to the two grocery chains (this may facilitate your flow balance equations).

A. Write down your model formulation in its entirety. (Note: This is a variant of a transshipment model; unpasteurized raw milk goes into the processing facilities but two productspasteurized milk and cream come out. You need to figure out how to model these new and different flow/balance equations.)

B. Solve your model in Excel and determine the optimal solution (i.e., optimal purchasing plan) and the total cost.

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts