Question: 2- We are separating an ethanol-water mixture in a column operating at atmospheric pressure with a total condenser and a partial reboiler. CMO can be

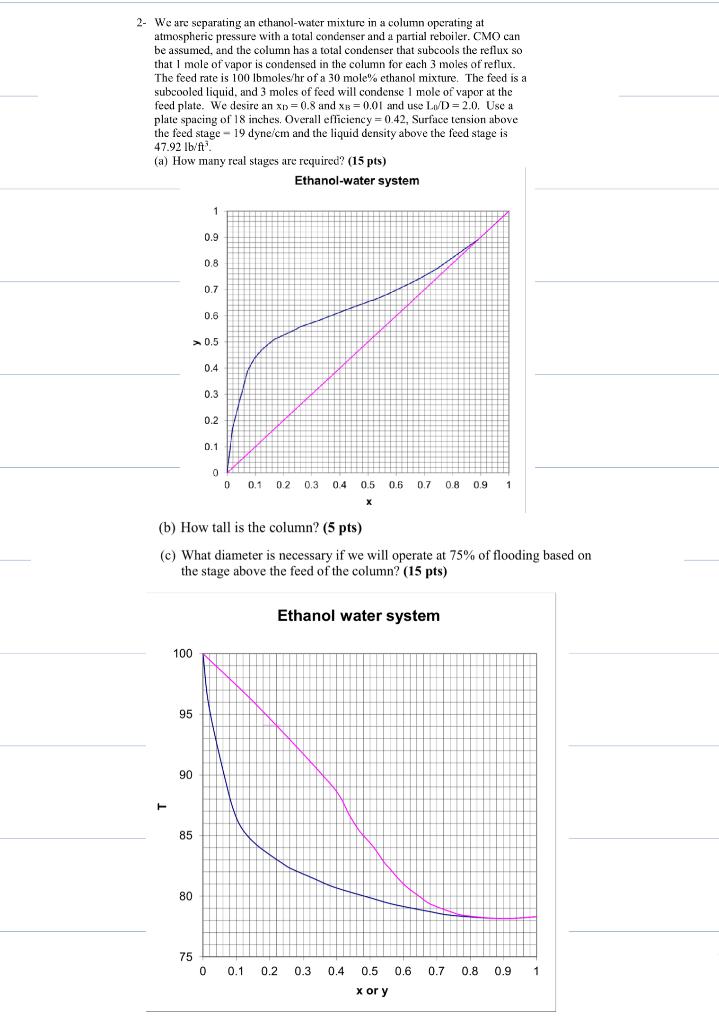

2- We are separating an ethanol-water mixture in a column operating at atmospheric pressure with a total condenser and a partial reboiler. CMO can be assumed, and the column has a total condenser that subcools the reflux so that 1 mole of vapor is condensed in the column for each 3 moles of reflux. The feed rate is 100lbmoles/hr of a 30mole% ethanol mixture. The feed is a subcooled liquid, and 3 moles of feed will condense 1 mole of vapor at the feed plate. We desire an xD=0.8 and xB=0.01 and use L0/D=2.0. Use a plate spacing of 18 inches. Overall efficiency =0.42, Surface tension above the feed stage -19 dyne/cm and the liquid density above the feed stage is 47.92lbft3 (a) How many real stages are required? (15 pts) (b) How tall is the column? (5 pts) (c) What diameter is necessary if we will operate at 75% of flooding based on the stage above the feed of the column? (15 pts)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts