Question: 2 - Why is time-to-market so important in the apparel industry? How does it impact supply chain processes? (10 Marks 3- Which trade-offs must be

2 - Why is time-to-market so important in the apparel industry? How does it impact supply chain processes? (10 Marks

3- Which trade-offs must be made when setting up a global SCM network for the apparel industry? Also, discuss the trade-offs regarding sourcing countries versus quality. (10 Marks)

plzz explain in brief both question

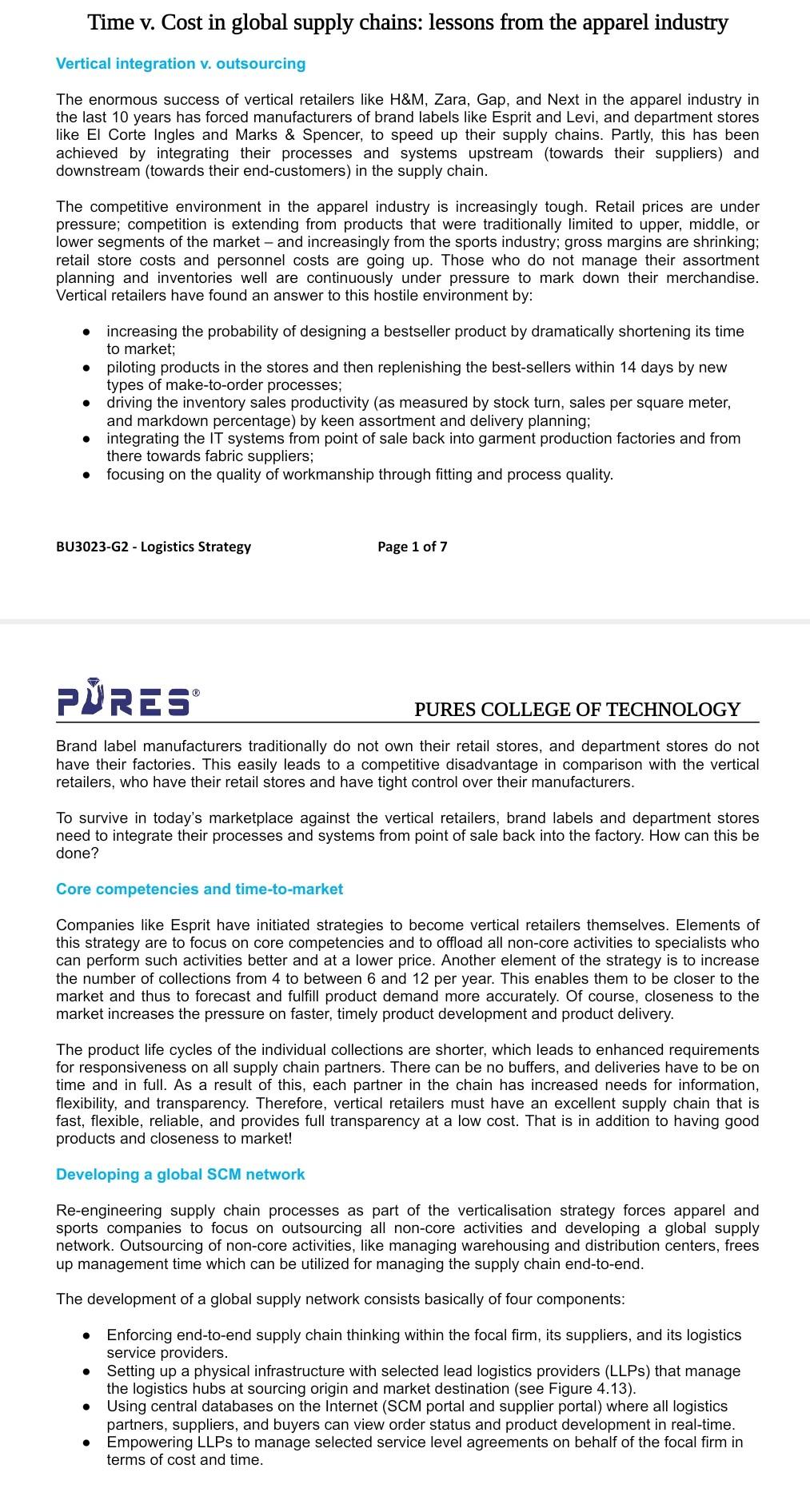

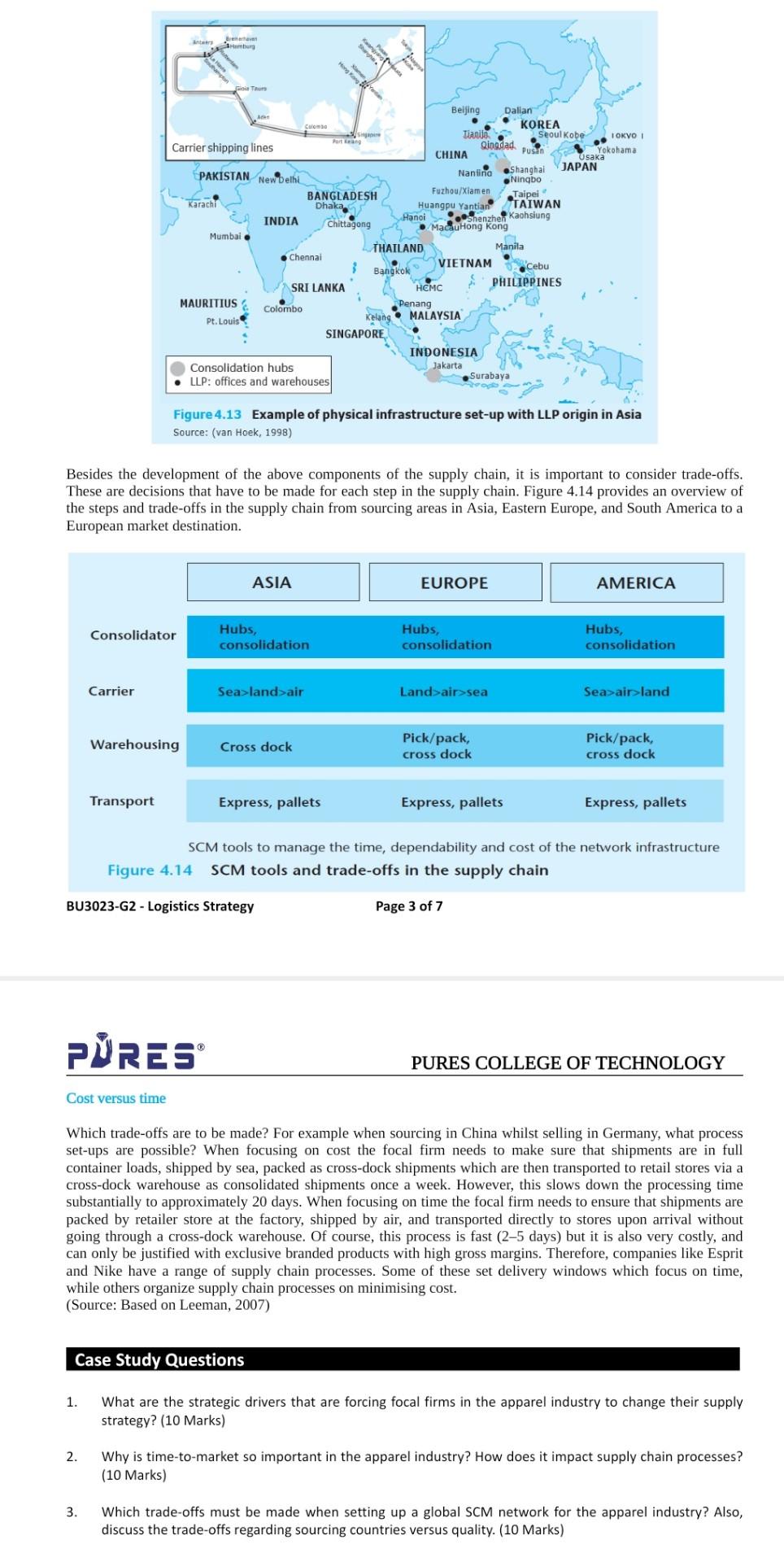

Time v. Cost in global supply chains: lessons from the apparel industry Vertical integration v. outsourcing The enormous success of vertical retailers like H\&M, Zara, Gap, and Next in the apparel industry in the last 10 years has forced manufacturers of brand labels like Esprit and Levi, and department stores like El Corte Ingles and Marks \& Spencer, to speed up their supply chains. Partly, this has been achieved by integrating their processes and systems upstream (towards their suppliers) and downstream (towards their end-customers) in the supply chain. The competitive environment in the apparel industry is increasingly tough. Retail prices are under pressure; competition is extending from products that were traditionally limited to upper, middle, or lower segments of the market - and increasingly from the sports industry; gross margins are shrinking; retail store costs and personnel costs are going up. Those who do not manage their assortment planning and inventories well are continuously under pressure to mark down their merchandise. Vertical retailers have found an answer to this hostile environment by: - increasing the probability of designing a bestseller product by dramatically shortening its time to market; - piloting products in the stores and then replenishing the best-sellers within 14 days by new types of make-to-order processes; - driving the inventory sales productivity (as measured by stock turn, sales per square meter, and markdown percentage) by keen assortment and delivery planning; - integrating the IT systems from point of sale back into garment production factories and from - there towards fabric suppliers; - focusing on the quality of workmanship through fitting and process quality. BU3023-G2 - Logistics Strategy Page 1 of 7 PURES COLLEGE OF TECHNOLOGY Brand label manufacturers traditionally do not own their retail stores, and department stores do not have their factories. This easily leads to a competitive disadvantage in comparison with the vertical retailers, who have their retail stores and have tight control over their manufacturers. To survive in today's marketplace against the vertical retailers, brand labels and department stores need to integrate their processes and systems from point of sale back into the factory. How can this be done? Core competencies and time-to-market Companies like Esprit have initiated strategies to become vertical retailers themselves. Elements of this strategy are to focus on core competencies and to offload all non-core activities to specialists who can perform such activities better and at a lower price. Another element of the strategy is to increase the number of collections from 4 to between 6 and 12 per year. This enables them to be closer to the market and thus to forecast and fulfill product demand more accurately. Of course, closeness to the market increases the pressure on faster, timely product development and product delivery. The product life cycles of the individual collections are shorter, which leads to enhanced requirements for responsiveness on all supply chain partners. There can be no buffers, and deliveries have to be on time and in full. As a result of this, each partner in the chain has increased needs for information, flexibility, and transparency. Therefore, vertical retailers must have an excellent supply chain that is fast, flexible, reliable, and provides full transparency at a low cost. That is in addition to having good products and closeness to market! Developing a global SCM network Re-engineering supply chain processes as part of the verticalisation strategy forces apparel and sports companies to focus on outsourcing all non-core activities and developing a global supply network. Outsourcing of non-core activities, like managing warehousing and distribution centers, frees up management time which can be utilized for managing the supply chain end-to-end. The development of a global supply network consists basically of four components: - Enforcing end-to-end supply chain thinking within the focal firm, its suppliers, and its logistics service providers. - Setting up a physical infrastructure with selected lead logistics providers (LLPs) that manage the logistics hubs at sourcing origin and market destination (see Figure 4.13). - Using central databases on the Internet (SCM portal and supplier portal) where all logistics partners, suppliers, and buyers can view order status and product development in real-time. - Empowering LLPs to manage selected service level agreements on behalf of the focal firm in terms of cost and time. Besides the development of the above components of the supply chain, it is important to consider trade-offs. These are decisions that have to be made for each step in the supply chain. Figure 4.14 provides an overview of the steps and trade-offs in the supply chain from sourcing areas in Asia, Eastern Europe, and South America to a European market destination. BU3023-G2 - Logistics Strategy Page 3 of 7 PURES COLLEGE OF TECHNOLOGY Cost versus time Which trade-offs are to be made? For example when sourcing in China whilst selling in Germany, what process set-ups are possible? When focusing on cost the focal firm needs to make sure that shipments are in full container loads, shipped by sea, packed as cross-dock shipments which are then transported to retail stores via a cross-dock warehouse as consolidated shipments once a week. However, this slows down the processing time substantially to approximately 20 days. When focusing on time the focal firm needs to ensure that shipments are packed by retailer store at the factory, shipped by air, and transported directly to stores upon arrival without going through a cross-dock warehouse. Of course, this process is fast (2-5 days) but it is also very costly, and can only be justified with exclusive branded products with high gross margins. Therefore, companies like Esprit and Nike have a range of supply chain processes. Some of these set delivery windows which focus on time, while others organize supply chain processes on minimising cost. (Source: Based on Leeman, 2007) Case Study Questions 1. What are the strategic drivers that are forcing focal firms in the apparel industry to change their supply strategy? (10 Marks) 2. Why is time-to-market so important in the apparel industry? How does it impact supply chain processes? (10 Marks) 3. Which trade-offs must be made when setting up a global SCM network for the apparel industry? Also, discuss the trade-offs regarding sourcing countries versus quality. (10 Marks)Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock