Question: 2.10) Consider the production planning problem discussed in Example 2.14 (Section 2.17). Assume now that backorders are allowed, that is, if we do not have

2.10) Consider the production planning problem discussed in Example 2.14 (Section 2.17). Assume now that backorders are allowed, that is, if we do not have sufficient stock, we can backorder so that the order can be supplied in a later week. However, this incurs a backorder penalty cost of $4 per unit per week. Reformulate this problem as an LP model assuming that all backorders must be filled by the end of the 4th week. It is sufficient you define all the variables, write out the constraints and the objective function.

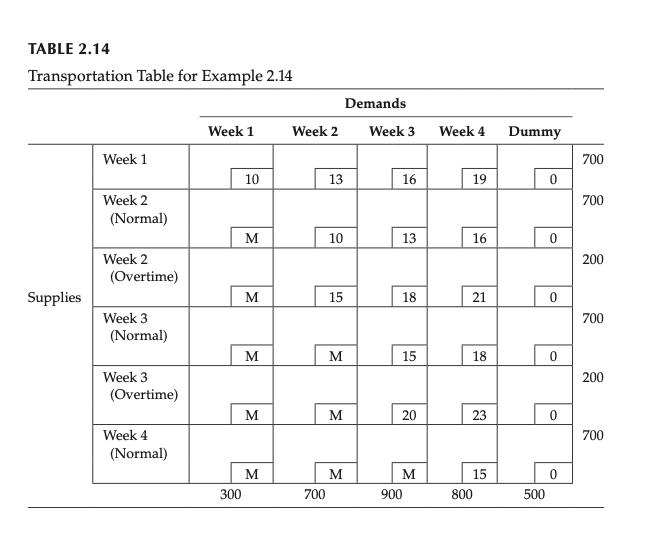

Example 2.14 (Ravindran et al., 1987)

Consider the problem of scheduling the weekly production of a certain item for the next 4 weeks. The production cost of the item is $10 for the first 2 weeks, and $15 for the last 2 weeks. The weekly demands are 300, 700, 900, and 800, which must be met. The plant can produce a maximum of 700 units each week. In addition the company can employ overtime during the 2nd and 3rd weeks. This increases the weekly production by an additional 200 units, but the production cost increases by $5 per item. Excess production can be stored at a unit cost of $3 per week. How should the production be scheduled so as to minimize the total costs?

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts