Question: 2.1.4 An Illustrative Example: Managing a Document Distribution Process The following example adapted from Melan (1993) illustrates the basic principles of pro- cess management discussed

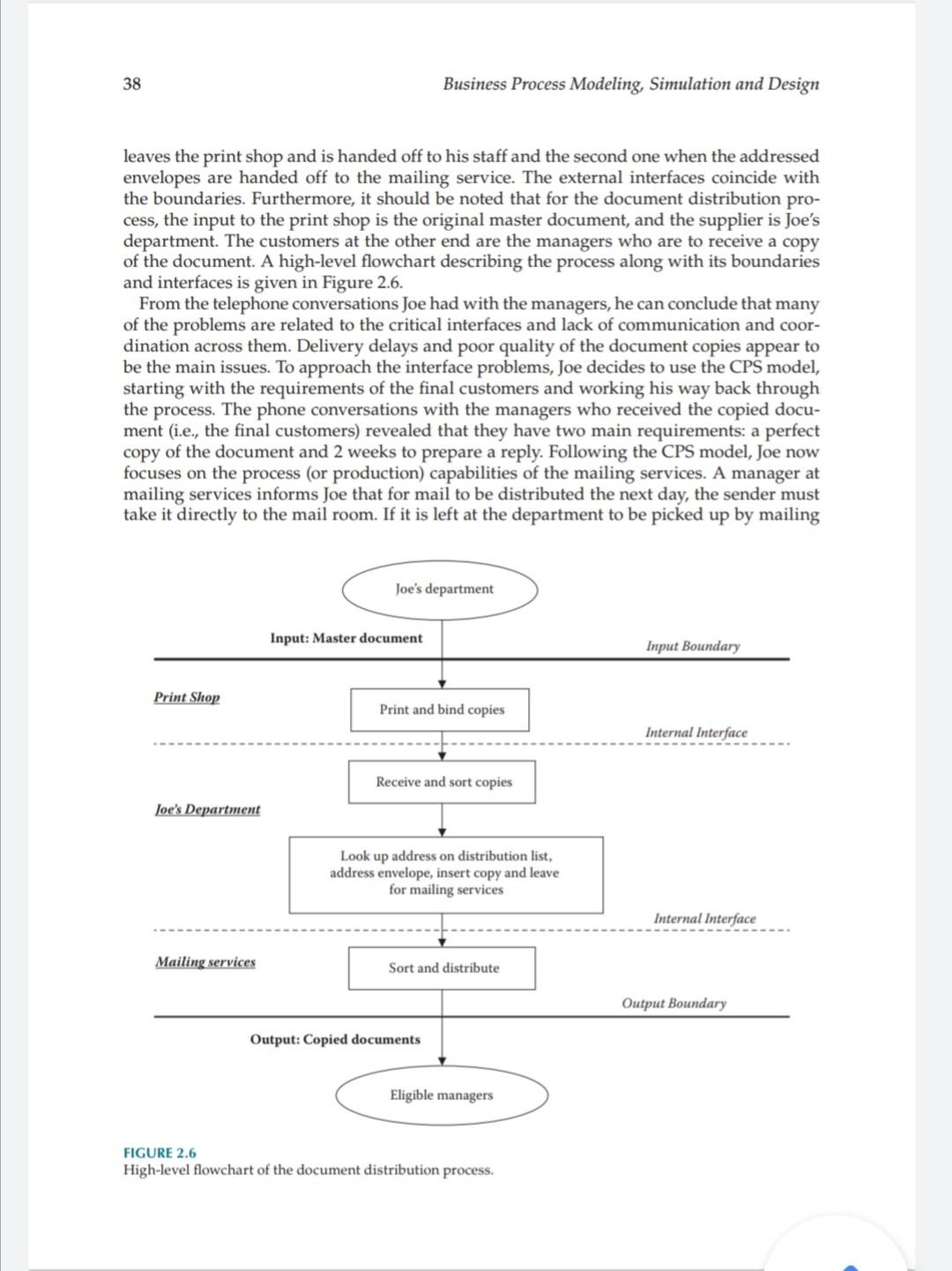

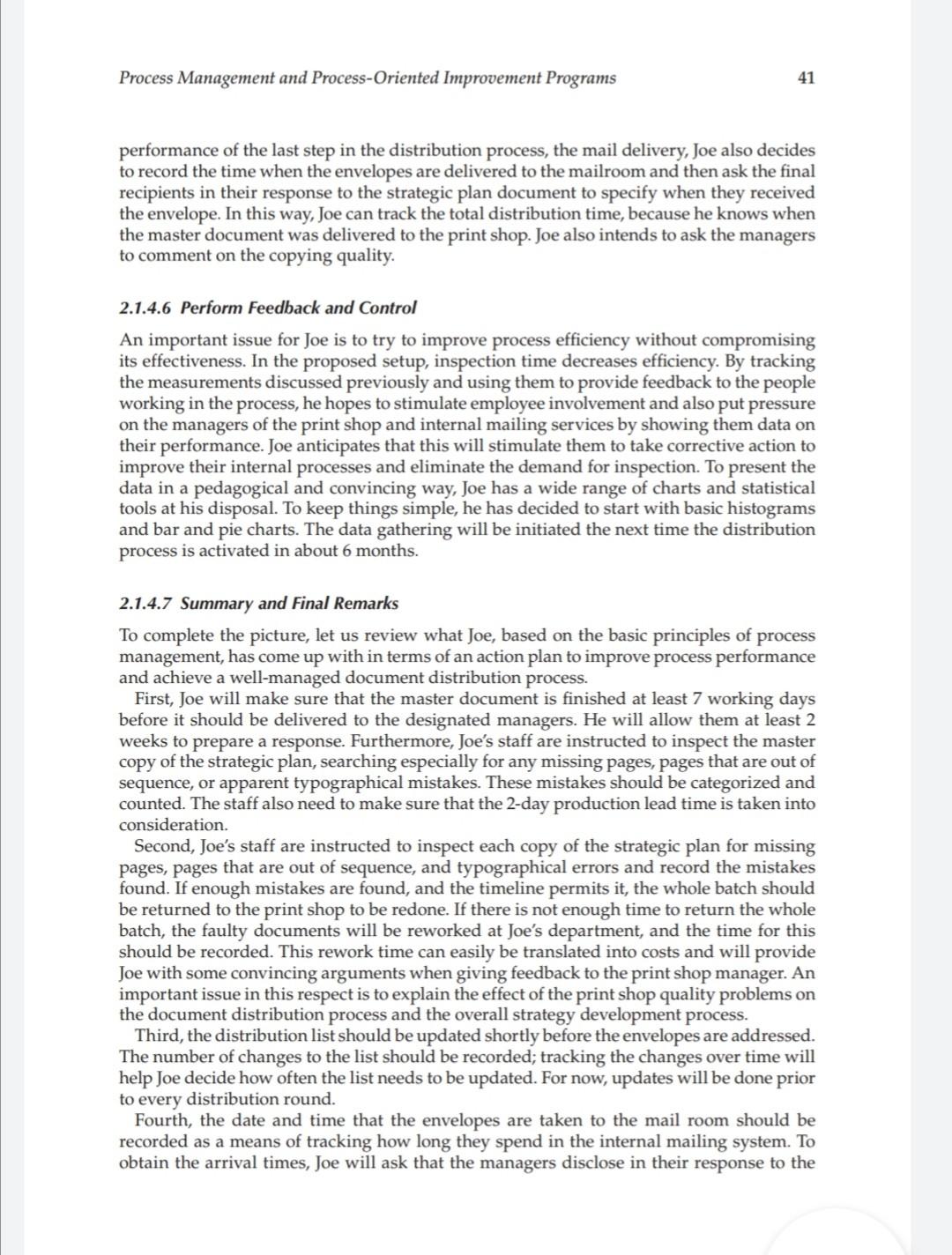

2.1.4 An Illustrative Example: Managing a Document Distribution Process The following example adapted from Melan (1993) illustrates the basic principles of pro- cess management discussed in this chapter thus far. Process Management and Process-Oriented Improvement Programs 37 Joe recently started his new position as associate manager of the business development department, with special responsibility for strategic planning. In January and in June, Joe is now responsible for formulating and issuing copies of the company's strategic plan to the firm's key managers. In fact, this is one of his more important functions. The manag- ers then have to respond to Joe within 2 weeks regarding a wide range of strategic issues before the plan can be finalized. The importance and visibility of this document mean that any kind of problems with the process will reflect badly on Joe personally and on his department. In early January, copies of the document were delivered from the print shop. Joe's staff then sorted the documents, put them in envelopes addressed to the designated managers, and left them to be picked up by internal mailing services. The address of each manager eligible to receive a copy was easily available from a distribution list kept by the depart- mental secretary. No mailing problems were reported to Joe. By mid-January, only four managers had responded to Joe, who was disappointed and embarrassed to report to his manager that he would not be able to finalize the strategic plan before the agreed dead- line. He then immediately began making phone calls to the 24 managers who had not responded and was astonished by their responses. Three had not yet received the document. Two had just received the document at their new location. Seven complained about missing pages. Four reported pages out of sequence. Five said they could not respond in only 1 week. Three had left the organization. The following day, Joe received a message from his manager asking him to be in the manager's office the next morning with an analysis of the problem and an action plan for how to avoid this type of debacle in the future. Clearly , this process was not well managed. The following pages will discuss how the basic principles of process management can be used to improve it. 2.1.4.1 Assign Process Ownership It is clear that Joe is the manager responsible for formulating and distributing the strategic plan document. Although he has no managerial control over the print shop or the mailing services, he is perceived as the owner of the entire process by his managers and is held accountable for its failure. Neither the print shop nor the mailing service is aware of its role in the process and that Joe is the owner of the process; they just perform an operation with- out understanding its impact. This is why it is important to clarify to all parties involved who the process owner is. 2.1.4.2 Analyze Boundaries and Interfaces With the process ownership in place, Joe needs to analyze the process boundaries and interfaces. Based on the detected problems, he decides to focus his attention on the docu- ment distribution process, starting when the print shop receives the original document to be copied and ending when the mailing services deliver the mailed copy to the managers. Joe also defines two critical internal interfaces: the first one when the job (i.e., the copies) 38 Business Process Modeling, Simulation and Design leaves the print shop and is handed off to his staff and the second one when the addressed envelopes are handed off to the mailing service. The external interfaces coincide with the boundaries. Furthermore, it should be noted that for the document distribution pro- cess, the input to the print shop is the original master document, and the supplier is Joe's department. The customers at the other end are the managers who are to receive a copy of the document. A high-level flowchart describing the process along with its boundaries and interfaces is given in Figure 2.6. From the telephone conversations Joe had with the managers, he can conclude that many of the problems are related to the critical interfaces and lack of communication and coor- dination across them. Delivery delays and poor quality of the document copies appear to be the main issues. To approach the interface problems, Joe decides to use the CPS model, starting with the requirements of the final customers and working his way back through the process. The phone conversations with the managers who received the copied docu- ment (i.e., the final customers) revealed that they have two main requirements: a perfect copy of the document and 2 weeks to prepare a reply. Following the CPS model, Joe now focuses on the process (or production) capabilities of the mailing services. A manager at mailing services informs Joe that for mail to be distributed the next day, the sender must take it directly to the mail room. If it is left at the department to be picked up by mailing Joe's department Input: Master document Input Boundary Print Shop Print and bind copies Internal Interface Receive and sort copies Joe's Department Look up address on distribution list, address envelope, insert copy and leave for mailing services Internal Interface Mailing services Sort and distribute Output Boundary Output: Copied documents Eligible managers FIGURE 2.6 High-level flowchart of the document distribution process. Process Management and Process-Oriented Improvement Programs 39 services, it takes an additional day before the envelopes are delivered to their recipients. Furthermore, if the mail is going to one of the company's satellite locations, which is the case for several managers on Joe's distribution list, it might take up to 4 days until the envelopes are delivered, assuming they are brought straight to the mail room. In the cur- rent process, the envelopes were left at Joe's department and the assumption was next-day delivery. The input to the mailing services is the addressed envelopes supplied by Joe's depart- ment. Consequently, following the CPS model and assuming that Joe intends to continue using the internal mailing services, the supplier requirements indicate that Joe needs to deliver the copied documents to the mail room 4 days earlier than was done this time to satisfy the customer requirements. Another option would be to use an external courier, but Joe has no room in his budget for that. An alternative would be to change the mailing services process to shorten the delivery time, but Joe has no managerial jurisdiction over mailing services, so this is not a viable option either. The next interface of interest is that between Joe's department and the print shop, where the former is the internal customer to the latter. The requirements posed by Joe's depart- ment are linked directly to the end-customer requirements: the copies should be of good quality and be delivered promptly. The manager of the print shop informs Joe that for a large-size document such as the strategic plan, a 2-day lead time is to be expected. A rush job increases the risk of receiving bad-quality copies. When the last job was done, Joe's secretary, not understanding the production capabilities, requested "same-day service" but received the copies 2 days later. Also, the print shop staff noticed a reversed sequence of page numbers but assumed that this was desired because that was how the original master document was arranged. The print shop just copies the master document as is. Assuming that Joe will continue using the print shop, understanding the print shop's capa- bilities renders some clear requirements on the supplier of the master document, which is Joe's department: the document must be in perfect shape and be delivered to the print shop 2 days before it needs to be sorted, addressed, and put in envelopes. To summarize, applying the CPS model has revealed some important requirements that Joe's department must take into account to get the copied documents out on a cer- tain day. Basically, the print shop needs the master document delivered in the morning of Day 1, and the master document must at this point be in perfect shape, because it is copied as is. The print shop delivers the copied documents to Joe's department in the morning of Day 3; then Joe's staff have half a day to sort, address, and deliver the sealed envelopes to the mail room. Internal mailing services guarantees delivery to all locations during Day 7. In addition to the timing issues that Joe must consider, his department also must pay special attention to the quality of the master document and the correctness of the distribution list. 2.1.4.3 Define the Process Having determined the scope of the process, Joe is in a position to define the activities and workflow that are within the boundaries. The most common approach is to start with a high-level flowchart, such as the one in Figure 2.6, and then create a hierarchy of successively more detailed flowcharts over the different subprocesses and activities until the right level of detail is obtained in the description. The right level is found when additional details no longer appear to offer further opportunities for improvement. In this particular case, Joe decides not to proceed beyond the high level or macro flowchart in Figure 2.6. 40 Business Process Modeling, Simulation and Design 2.1.4.4 Establish Control Points The current process does not contain any internal control points; as a result, Joe might not realize that something is wrong with the process until it is too late. This situation repre- sents a high failure cost for Joe in terms of lost credibility within the firm. Based on the customer feedback and the analysis so far, Joe finds three instances where control points appear to make sense. 1. Inspection of the master document before it is delivered to the print shop to ensure that what goes to the print shop is flawless. This responsibility falls on Joe's secre- tary and his other staff members. 2. Inspection of the copies received from the print shop by Joe's staff before they are put into envelopes and mailed. This is done to ensure that pages are not miss- ing and that pictures are not blurred due to quality problems in the print shop. Applying the CPS model, Joe should negotiate with the print shop and require them to change their process to avoid quality problems of this sort. This would make the inspection of the final copies redundant and save Joe some resources. However, even if Joe has enough clout to make this happen, it makes sense in the short run to install the control point to make sure the print shop process performs as intended, simply because the outcome is so important to Joe. 3. Verification that the distribution list is accurate (the right people are on it, and their addresses are correct). This job is appropriate for Joe's staff. The purpose is to avoid sending copies to those who are no longer with the company or sending copies to the wrong address. The problem is magnified by the confidentiality of the strategy document. As the quality of the process improves, these inspections will become redundant. Installing inspection points is not an efficient way to achieve quality output in the long run. However, it enables data gathering and identification of the root causes of problems occurring in dysfunctional processes. 2.1.4.5 Develop and Implement Measures After determining the control points, the next step for Joe is to specify what to measure. Starting with the inspection of the master document at Control Point 1, it is important to record not just that a mistake occurred but what the mistake is. This assures that the data can be used to facilitate root cause analysis and improve the process that produces the original master document. Based on the customer feedback, it appears that the frequency of missing pages and pages out of sequence should be tracked. In addition, it seems wise to look for typographical errors, the types of mistakes, and their frequency. Control Point 2, dealing with the quality of the copies coming out of the print shop, will focus again on document quality, so the same measures should be used (i.e., frequency of missing pages; pages out of sequence; and a range of typographical errors including blurred figures, text alignment, and so on). For Control Point 3, the verification of distribution list accuracy, interesting measures to track are the number of address changes and the turnover of managers on the list. Joe decides to use these categorized frequency measures to track the copying and address quality. In addition to the three internal control points, Joe also decides to solicit regular feed- back from the end customers regarding copy quality and delivery time. To track the Process Management and Process-Oriented Improvement Programs 41 performance of the last step in the distribution process, the mail delivery, Joe also decides to record the time when the envelopes are delivered to the mailroom and then ask the final recipients in their response to the strategic plan document to specify when they received the envelope. In this way, Joe can track the total distribution time, because he knows when the master document was delivered to the print shop. Joe also intends to ask the managers to comment on the copying quality. 2.1.4.6 Perform Feedback and Control An important issue for Joe is to try to improve process efficiency without compromising its effectiveness. In the proposed setup, inspection time decreases efficiency. By tracking the measurements discussed previously and using them to provide feedback to the people working in the process, he hopes to stimulate employee involvement and also put pressure on the managers of the print shop and internal mailing services by showing them data on their performance. Joe anticipates that this will stimulate them to take corrective action to improve their internal processes and eliminate the demand for inspection. To present the data in a pedagogical and convincing way, Joe has a wide range of charts and statistical tools at his disposal. To keep things simple, he has decided to start with basic histograms and bar and pie charts. The data gathering will be initiated the next time the distribution process is activated in about 6 months. 2.1.4.7 Summary and Final Remarks To complete the picture, let us review what Joe, based on the basic principles of process management, has come up with in terms of an action plan to improve process performance and achieve a well-managed document distribution process. First, Joe will make sure that the master document is finished at least 7 working days before it should be delivered to the designated managers. He will allow them at least 2 weeks to prepare a response. Furthermore, Joe's staff are instructed to inspect the master copy of the strategic plan, searching especially for any missing pages, pages that are out of sequence, or apparent typographical mistakes. These mistakes should be categorized and counted. The staff also need to make sure that the 2-day production lead time is taken into consideration Second, Joe's staff are instructed to inspect each copy of the strategic plan for missing pages, pages that are out of sequence, and typographical errors and record the mistakes found. If enough mistakes are found, and the timeline permits it, the whole batch should be returned to the print shop to be redone. If there is not enough time to return the whole batch, the faulty documents will be reworked at Joe's department, and the time for this should be recorded. This rework time can easily be translated into costs and will provide Joe with some convincing arguments when giving feedback to the print shop manager. An important issue in this respect is to explain the effect of the print shop quality problems on the document distribution process and the overall strategy development process. Third, the distribution list should be updated shortly before the envelopes are addressed. The number of changes to the list should be recorded, tracking the changes over time will help Joe decide how often the list needs to be updated. For now, updates will be done prior to every distribution round. Fourth, the date and time that the envelopes are taken to the mail room should be recorded as a means of tracking how long they spend in the internal mailing system. To obtain the arrival times, Joe will ask that the managers disclose in their response to the 42 Business Process Modeling, Simulation and Design strategic plan exactly when the document was delivered. He also will ask them to com- ment on the document copying quality. By implementing these changes, Joe takes a huge step toward proactive process man- agement, so that he can avoid situations in which the process problems are not discovered until it is too late to correct them. Joe is also in a good position to explain to his boss at their meeting the next day what caused the problems with the document distribution process and what he plans to do to prevent future mishaps of this kind. Apart from the immediate actions to assure the effectiveness of the process in the near future, Joe also can point to the necessary long-term improvements. If the print shop and mailing services improve their internal efficiency, Joe can eliminate the inspection activities and thereby improve the overall efficiency of the document distribution process. Most likely, drastic improvements could be made to the process performance in the print shop and the mailing services if their managers were willing to rethink their entire design. 5. Considering the document distribution example in Section 2.1.4: a. What would you say are the main problems with the management of this process? b. Do you agree with Joe's approach for arriving at a better-managed process? c. Is there anything you would do differently? d. Do you see any potential for radical redesign of the entire process? What do you suggest

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock